Creative Woodworks & crafts 2005-04, страница 72

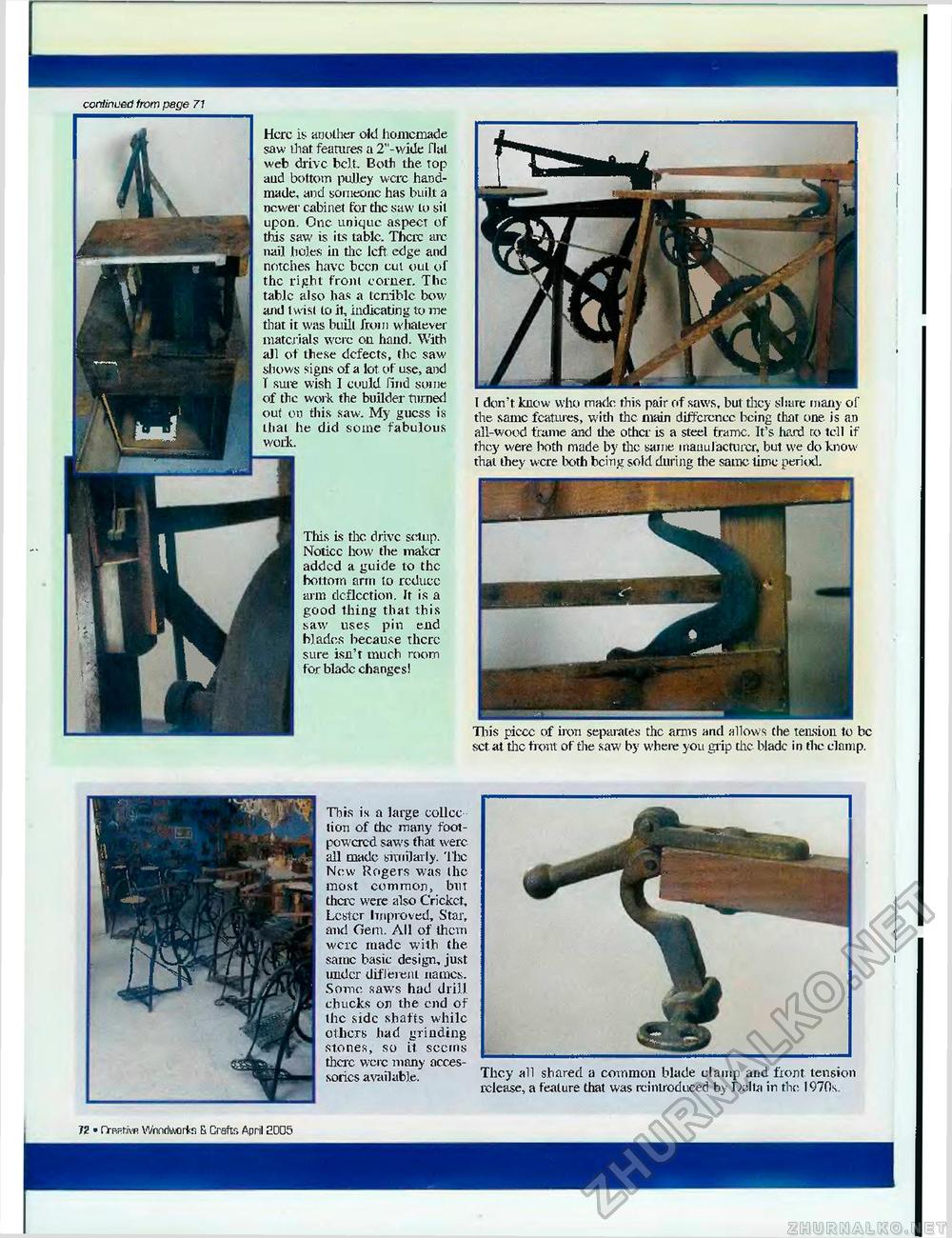

This is the drive setup. Noticc how the maker added a guide to the hottotn ami to reduce arm dcflcction. It is a good thing that this saw uses pin end blade,s because There sure isn't much room for blade changes! continued from page 7 J Here is another old homemade saw that features a 2"-wide flat web drive belt. Both the top and bottom pulley were handmade, and someone has built a newer cabinet tor die saw to sit upon. One unique aspect of this saw is its tabic. There arc nail holes ill the left edge and notches have been cut out of the light front corner. The tabic also has a terrible bow and twist to it, indicating to me that it was built from whatever materials were on hand. With all of these dcfects, the saw shows signs of a lot of use, and f sure wish I could find some of the work the builder turned out on this saw. My guess is that he did some fabulous work. Tliis piccc of iron separates the arms and allows the tension to be set at the front of the saw by where you grip the blade in the clamp. I don't know who made this pair of saws, but they share many of the same features, with the main difference being that one is an all-wood frame and tlie other is a steel frame. It's hard ro tell if they were both made by the same manufacturer, but. we do know that they w-cre both being sold during the same time period. This is a large collcc lion of the many foot-powered saws that were all made similarly. The New Rogers was the most common, but there were also Crickct, Lester Improved, Star, and Gem. All of them were made with the same basic design, just under diflereni names. Some saws had drill chucks on the end of the side shafts while others had grinding stones, so it seems there were many accessories available. They all shared a common blade clamp and front, tension release, a feature that was reintroduced by Delta in the 1970s IS ' n-RRtivn Wrinriworta & Crafts April 2005 |