Creative Woodworks & crafts 2005-06, страница 77

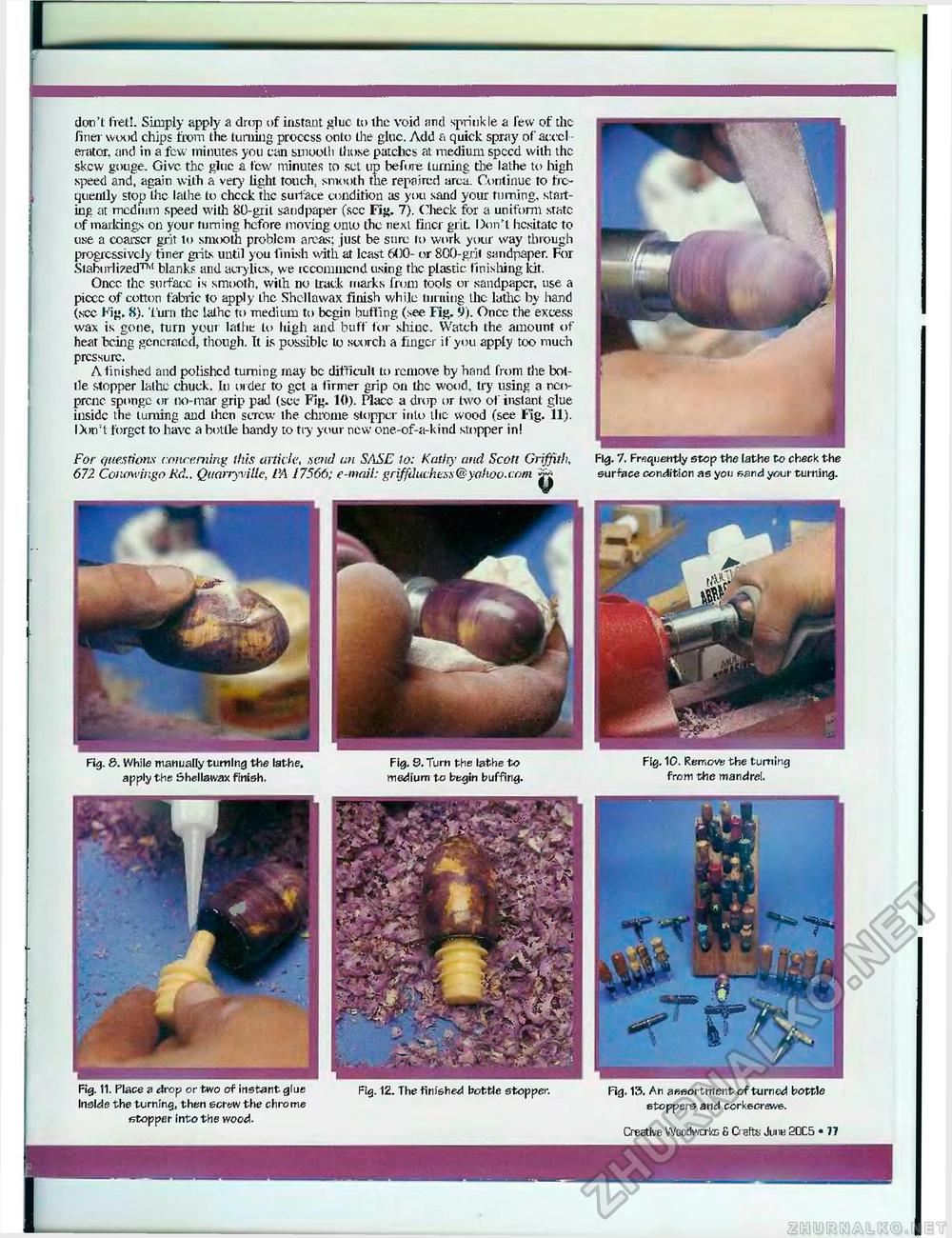

don't fret!. Simply apply a drop of instant glue to the void and sprinkle a few of the finer wood chips from the turning process onto the glue. Add fi quick spray of accelerator, and in a few minutes you can smooth those patchcs at medium speed with the skew gouge. Give the glue a few minutes to set up be fine turning the lathe to high speed and, again with a very light touch, smooth the. repaired area.. Continue to frequently stop the lathe to check the surface condition as you sand your turning, starting at medium speed with 80-grit sandpaper (see Fig. 7). Check for a uniform state of markings on your fuming before moving onto the next finer grit. Don't hesitate to use a coarscr grit to smooth problem areas; just be sure to work your way through progressively finer grits until you finish with at least 600- or 800-grii sandpaper. For Stahurlized™ blanks and. acrylics, we iccommcnd using the plastic finishing kit. Oncc. the snrfacc is smooth, wilh no track marks from tools or sandpaper, use a piece of cotton fabric to apply the Shellawax finish while turning the lathe by hand (see Fig. 8). Turn the Lathe to medium to begin buffing (see Fig. 9). Oncc the excess wax is gone, turn your lathe to high and buff for shine. Watch the amount of heat being generated, though. It is possible to scorch a finger if you apply too much pressure. A finished and polished turning may be difficult to remove by hand from the bottle stopper lalhe chuck, hi order to get a firmer grip on the wood, try using a nco-prc.nc sponge or no-mar grip pad (see Fig. 10). Place a drop or two of instant glue inside the turning and then screw the chrome stopper into the wood (see fig. 11). Don't forget to have a bottle handy to try your new one-of-a-kind stopper in! For questions concerning this article, send an SASE to: Kathy and Scott Griffith, 672 Conowingo Rcl. Quarryville, PA 17566; e-mail: griffduchess©yahoo.com jft Fig. 8. While manually turning the lathe. Fig. 9. Turn the lathe to apply the Shellawax finish. medium to begin buffing. Fig. 11. Place a drop or two of instant glue Fig. 12. The finished bottle stopper. Inside the turning, then screw the chrome stopper into the wood. Fig. 7. Frequently stop the lathe to check the surface condition as you sand your turning. Fig. 10. Remove the turning from the mandrel. Fig. 13. An assortment of turned bottle stoppers and corkscrews. Creative Woodwcrkc S Crafts Junu 20C5 • 11 |