Creative Woodworks & crafts 2005-08, страница 33

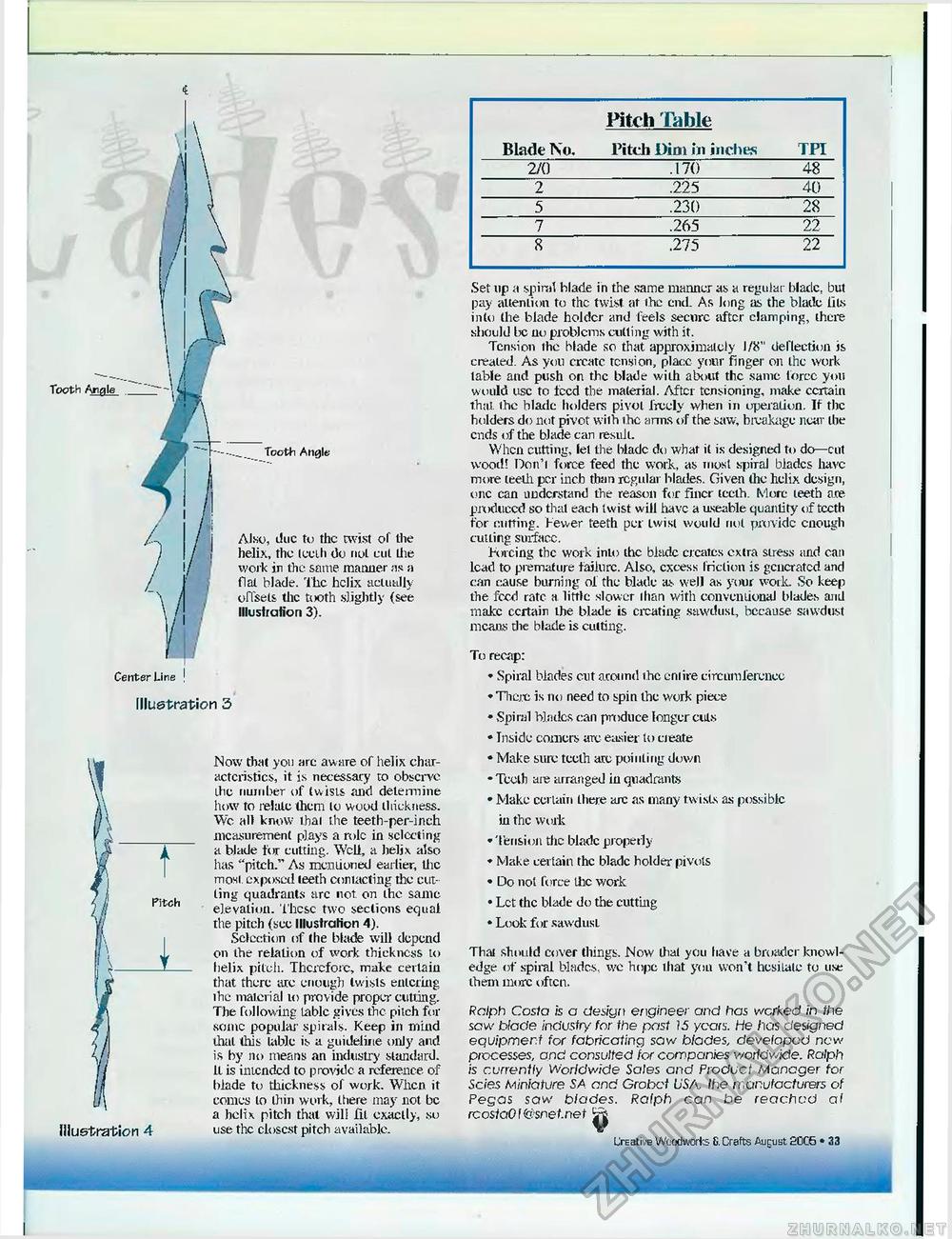

Tooth Angle A ----- Tooth Angle Also, due to the twist of the helix, the lecih do not cut the work in the same manner as a flat blade. The helix actually offsets the tooth slightly (see Illustration 3). Center Line ! Illustration 3 \1 t Pitch i Illustration 4 Now that you are aware of helix characteristics, it is necessary to observe the number of (wisis and determine how to relate them lo wood thickness. Wc alt know that the teeth-per-inch measurement plays a role in selecting a blade for cutting. Well, a helix also has "pitch." As mentioned earlier, the most. exposed teeth contacting the cutting quadrants arc not on the same elevation. These two sections equal the pitch (see Illustration 4). Selection of the blade will depend on the relation of work thickness to helix flitch. Therefore, make certain that there are enough twists entering the material to provide proper cutting. The following tabic gives the pitch for some popular spirals. Keep in mind that this table is a guideline only and is by no means an industry standard. 11 is inicndcd to provide a reference of blade to thickness of work. When it comes lo thin work, there may not be a helix pitch that will fit exactly, .so use the closest pitch available.

Set up a spiral blade in the same manner as a regular blade, but pay attention to the twist at the end. As long as the blade tils into the blade holder and feels seenre after clamping, there should lie no problems cutting with it. Tension ihe blade so that approximately 1/8" deflection is created. As you crcatc tension, placc your finger on the work table and push on the blade with about the same force you would use to feed the material. After tensioning, make certain that, the blade holders pi vol freely when in operation. If the holders do not pivot with the arms of the saw, breakage near ihe ends of the blade can result. When cutting, fel the blade do what i( is designed to do—cat wood! Don't force feed the work, as most spiral blades have more teeth per inch than regular blades. Given the helix design, one can understand the reason for finer teeth. More teeth ace produced so that each twist will have a useable quantity of teeth for cutting, hewer teeth per twisi would not provide enough cutting surfacc. forcing the work into the blade creates extra stress and can lead to premature failure. Also, cxcess friction is generated and can cause burning ol the blade at- well as your work. So keep the feed rate a little slower than with conventional blades and make certain the blade is creating sawdust, because sawdust means die blade is cutting. To recap: * Spiral blades cut around the entire circumference ♦ There is no need to spin the work piece * Spiral blades can produce longer euls • Inside comers are easier to cteate * Make sure teeth are pointing down - Teeth ate arranged in quadrants • Make certain there are as many twists as possible in the work * Tension the blade properly ♦ Make certain the blade holder pivots • Do not force the work • Let the blade do the cutting ♦ Look for sawdust That should cover things. Now thai you have a broader knowledge of spiral blades, we hope that you won't hesitate to use them more often. Ralph C.osla is a design engineer and has worked in fhe saw blade industry for the past 15 years. He has designed equipment for fabricating saw blades, developed new processes, and consulted for companies wortaV/ide. Ralph is currently Worldwide Sales and Product Manager for Scies Miniature SA and Grobct USA Ihe manufacturers of Pegas saw blades. Ralph can be reachcd al rcosfaOF@snef.net jjyj UrEstive Woodworks S. Crafts Aucuat 20C6 * 33 |