Creative Woodworks & crafts 2005-08, страница 46

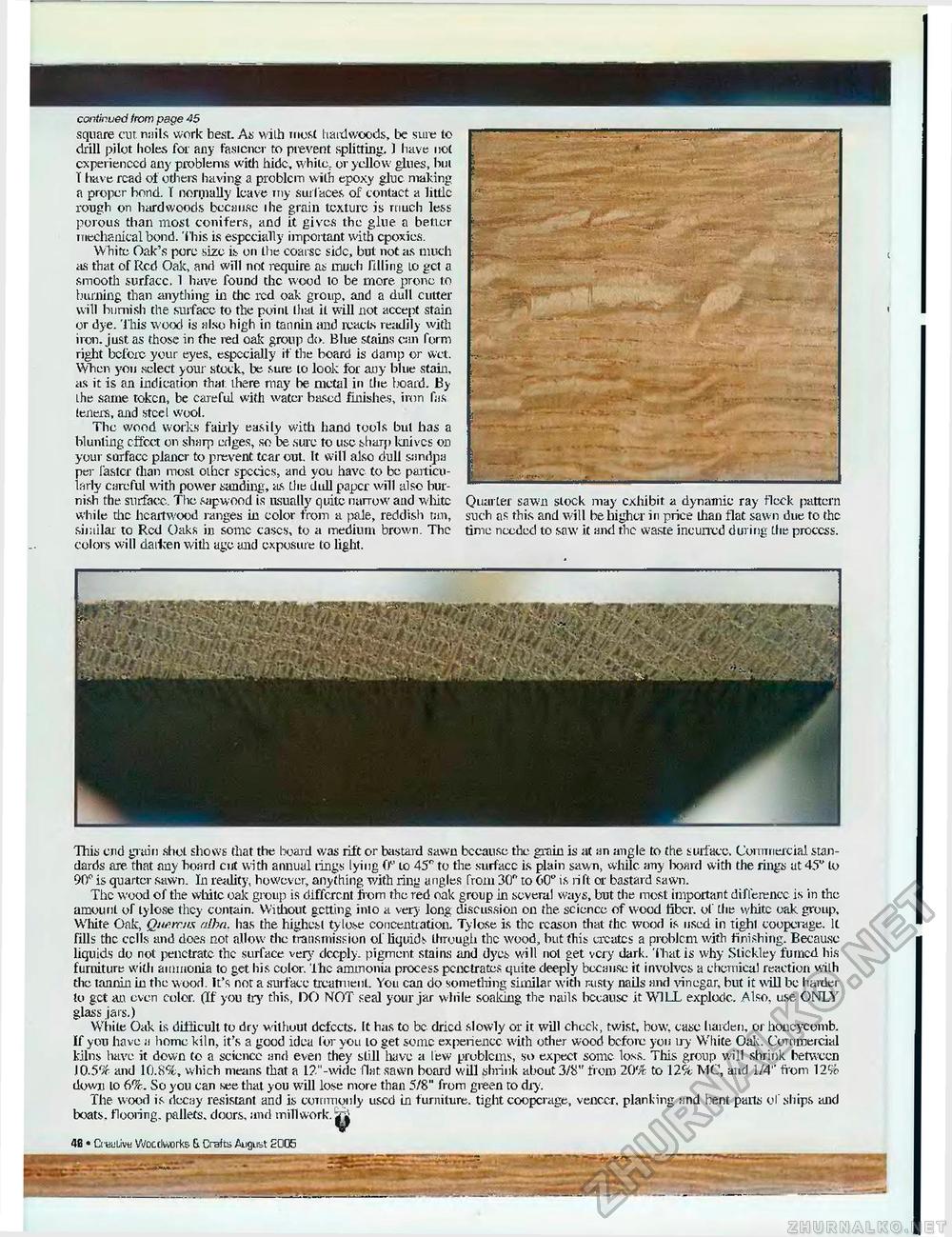

continued from page 45 square cut. nails work best. As wilh most haul woods, be sure to drill pilot holes for any fasicner to pr event splitting. 1 have not experienced any problems with hide, white, or yellow glues, but T have read of others having a problem with epoxy glue making a proper bond. 1 normally leave my surfaces of contact a little rough on hardwoods because ihe grain texture is much less porous than most conifers, and it gives the glue a better mechanical bond. This is especially important with cpoxies. White Oak's pore size is on the coaisc side, but not as much as that of Red Oak, and will not require as much filling to get a smooth surface. 1 have found the wood to be more prone to burning than anything in the red oak group, and a dull cutter will burnish the surface to the point lliat it will not accept stain or dye. This wood is also high in tannin and reacLs readily with iron, just as those in the red oak group do. Blue stains can form right before your eyes, especially if the board is damp or wet. When you select your stock, be sure to look for any blue stain, as it is an indication that, there may be metal in the board. By ihe same token, be careful with water based finishes, iron fas leners, and steel wool. The wood works fairly easily with hand tools but has a blunting effect on sharp edges, so be sure to use sharp knives on your surface planer to prevent tear out. It will also dull s; in dp a per faster than most oihcr species, and you have to be particularly careful with power sanding, <ls the dull paper will also burnish the surface. The sapwnod is usually quite narrow and white while die hcaitwood ranges in color from a pale, reddish tan, similar to Red Oaks in sonic eases, to a medium brown. The colors will daitcen with age and exposure to light. Quarter sawn stock may exhibit a dynamic ray fleck pattern such as this and will be higher in price than flat sawn due to the time needed to saw it and the waste incurred during the process. This end grain shot shows that the board was rift or bastard sawn because the grain is at an angle to the surface. Commercial standards are that any board cut with annual tings lying (P to 45" to the surfacc is plain sawn, while any lx>ard with the rings at 45" to 90° is quarter sawn. In reality, however, anything with ring angles from 30" to CO" is rift or bastard sawn. The wood of the white oak group is different from the red oak group in several ways, but the most important difference is in the amount of tylose they contain. Without getting into a very long discussion oil the. science of wood liber, of the white oak group, Wliite Oak, Que mis alhn. has the highest tylose concentration. Tylose is the reason that the wood is used in tighl cooperage. It fills the eclls and does not allow the transmission of liquids through the wood, but this creates a problem with finishing. Because liquids do not penetrate the surface very deeply, pigment stains and dyes will not get very dark. That is why Stickley fumed his furniture with ammonia to get his color, 'ihe ammonia process penetrates quite deeply because it involves a chemical reaction wilh the tannin in the wood. It's not a surface treatment. You can do something similar with rusty nails and vinegar, but it will be harder lo get an even color. (If you try this, DO NOT seal your jar while soaking the nails because it WILL explode. Also, use ONLY glass jars.) White Oak is difficult to dry without dcfccts. It has to be dried slowly or it will check, twist, bow, case harden, or honeycomb. If you have ;i home kiln, it's a good idea for you to get some experience with other wood before you iry White Oak. Commercial kilns have it down to a science and even they still have a lew prublcms, so expect some loss. This group will shrink between 10.5% and 10.8%, which means that a 12"-wide flat sawn board will shrink about 3/8" from 20% to 12% MC, and 1/4" from 12% down to 6%. So you can see that you will lose more than 5/8" from green to dry. The wood is decay resistant and is commonly used in furniture, tight coopcrage, veneer, planking and bent pans oI ships and boats, flooring, pallets, doors, and mill work, gi Ci euLivt; Woctlworks G. Crafts August £005 ___ -"-assi " *'" XiliV*-*0""!;- <w —p" .3.' - — —........ :**— I" ' ■ mix |