Creative Woodworks & crafts 2005-08, страница 62

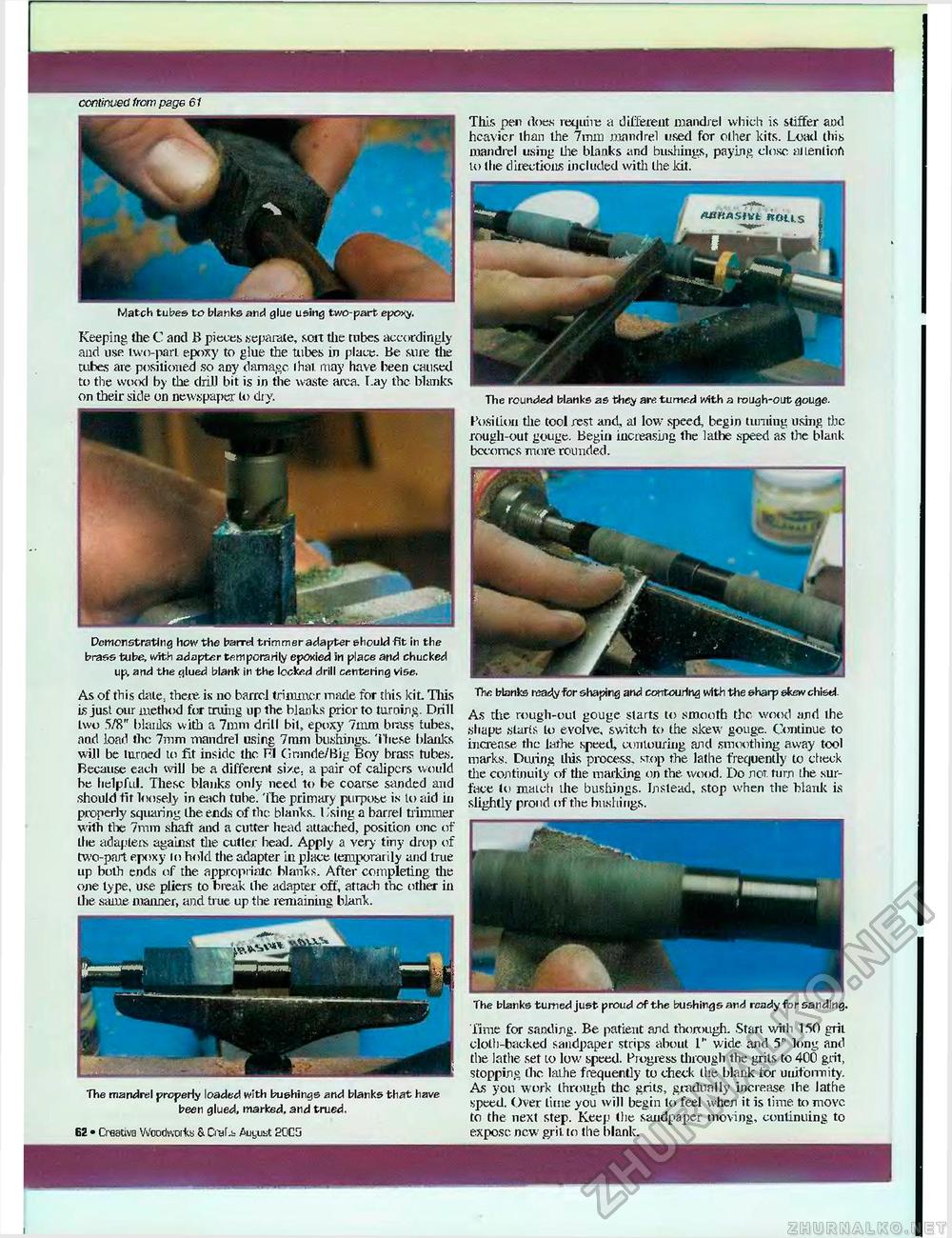

continued from page 61 This pen does require a different mandrel which is stiffer and heavier than the 7mm mandrel used for other kits. Load this mandrel using Lie blanks and bushings, paying close aitenlioft u> the directions included witli the kit. Match tubes to blanks and glue using two-part eposy. Keeping the C and B pieces separate, sort tlie tubes accordingly and use two-part epoxy to glue the tubes in place. Be sure tlie tubes are positioned so any damage-1 hat may have been caused to the wood by the drill bit is in the waste area. Lay the blanks on their side on newspaper to dry. Tlie rounded blanks as they are turned with a rough-out gouge. Position tlie tool .nest and, at low speed, begin turning using thorough-out gouge. Begin increasing the lathe speed as the blank becomcs more rounded. Demon strati 11 g how the barrel trimmer adapter should fit in the brass tube, with adapter temporarily epoxied in place and chucked up, and the cjtued blank in the locked drill centering vise. The blanks turned just proud of the bushings and ready for sanding. As of this date, there is 110 barrel trimmer made for this kit. This is just our method for truing up the blanks prior to turning. Drill two 5/8" blanks with a 7mm drill bit, epuxy 7mm brass tubes, and load the 7mm mandrel using 7mm bushings. These blanks will be lurried to fit inside the F1 Grande/Big Boy brass tubes. Because each will be a different size, a pair of calipers would be helpful. These blanks only need to be coarse sanded and should fir loosely in each tube, 'fhe primary purpose is to aid in properly squaring the ends of the blanks. L'sing a barrel trimmer with tlie 7mm shaft and a cutter head attached, position one of the adapters against tlie cutter head. Apply a very tiny drop of two-part epoxy lo hold the adapter in place temporarily and true up both ends of the appropriate blanks. After completing the one type, use pliers to break the adapter off, attach the other in tlie same manner, and true up the remaining blank. Ttie blanks ready for shaping arid contouring with the sharp skew chisel. As the rough-out gouge starts to smooth the wood and the shape starts to evolve, switch to the skew gouge. Continue to increase the lathe speed, contouring and smoothing away tool marks. Diuing this process, stop the lathe frequently to check tlie continuity of the marking on the, wood. Do not turn the surface to maich the bushings. Instead, stop when the blank is slightly proud of the bushings. The mandrel property loaded with bushings and blanks that have been glued, marked, and trued. 62 • Creative Woodworks & Ci-df-b August 20C5 Time for sanding. Be patient and thorough. Start with 150 grit cloth-backed sandpaper strips about 1" wide and 5" long and the lathe set to low speed. Progress through the grits to 400 grit, stopping the lathe frequently to check the blank for uniformity. As yon work through the grits, gradually increase ihe lathe speed. Over time you will begin to feel when it is lime to move to the next step. Keep the sandpaper moving, continuing to expose new grif. to the blank. /WfASIVt ROU S |