Creative Woodworks & crafts 2005-11, страница 70

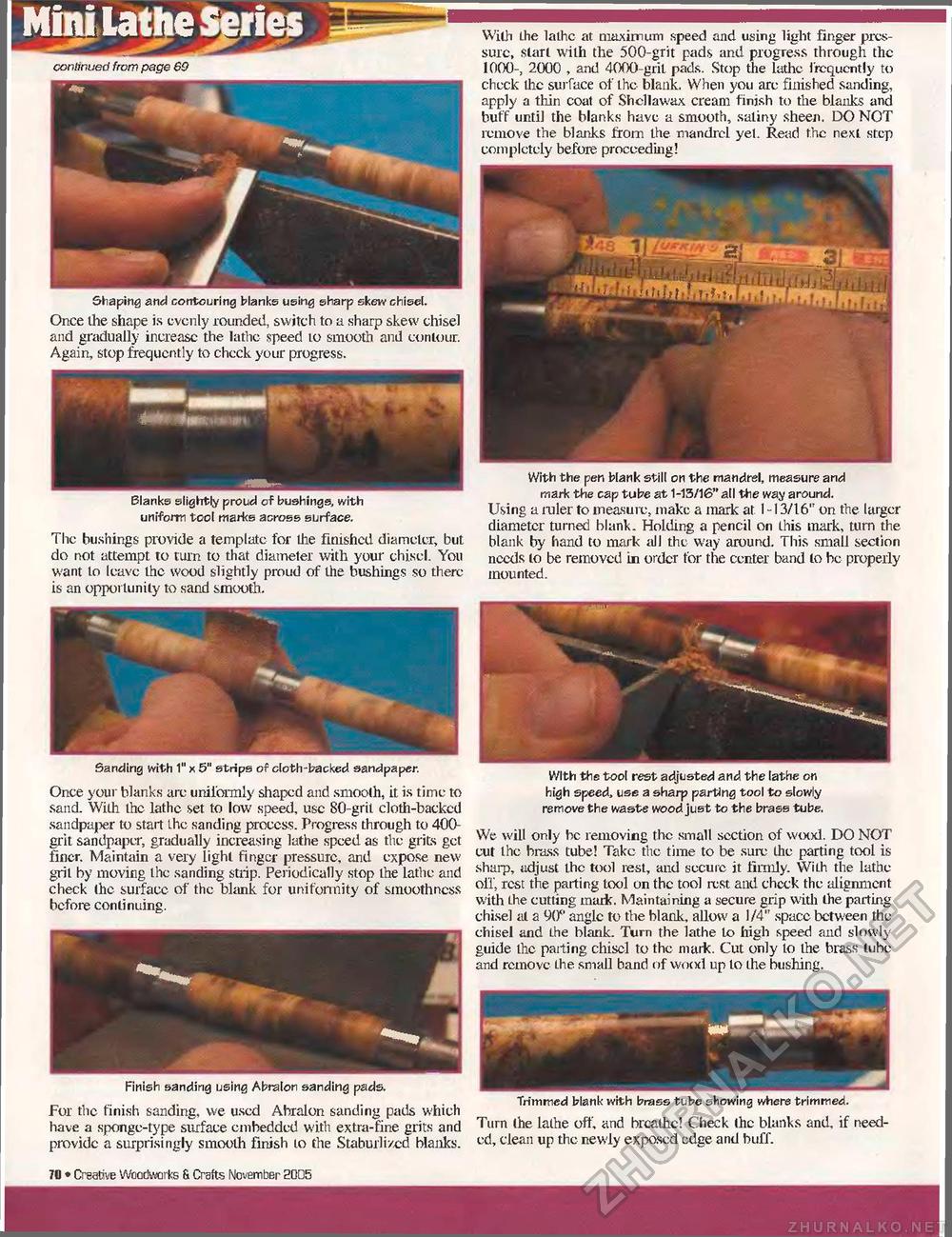

continued from page 29 1 Shaping and contouring blanks using sharp skew chisel. Once the shape is evenly rounded, switch to a sharp skew chisel and gradually increase the lathe speed to smooth and contour. Again, stop frequently to check your progress. Shaping and contouring blanks using sharp skew chisel. Once the shape is evenly rounded, switch to a sharp skew chisel and gradually increase the lathe speed to smooth and contour. Again, stop frequently to check your progress.

Sanding with 1" x 5" strips of cloth-backed sandpaper. Sanding with 1" x 5" strips of cloth-backed sandpaper. Once your blanks arc uniformly shaped and smooth, it is time to sand. With the lathe set to low speed, use 80-grit cloth-backcd sandpaper to start the sanding proccss. Progress through to 400-grit sandpaper, gradually increasing lathe speed as the grits get finer. Maintain a very light finger pressure, and expose new grit by moving the sanding strip. Periodically stop the lathe and check the surface of the blank for uniformity of smoothness before continuing. With the lathe at maximum speed and using light finger pressure, start with the 500-grit pads and progress through the 1000-, 2000 , and 4000-grit pads. Stop the lathe frequently to check the surface of the blauk. When you are finished sanding, apply a thin coat of Shcllawax cream finish to the blanks and buff until the blanks have a smooth, satiny sheen. DO NOT remove the blanks from the mandrel yet. Read the next step completely before proceeding! 2J ^MfSlffiDfl! With the pen blank still on the mandrel, measure and mark the cap tube at 1-13/16" all the way around. Using a ruler to measure, make a mark at I - 13/16" on the larger diameter turned blank. Holding a pencil on this mark, turn the blank by hand to mark all the way around. This small section needs to be removed in order for the center band lo be properly mounted. With the tool rest adjusted and the lathe on high speed, use a sharp parting tool to slowly remove the waste wood just to the brass tube. We will only be removing the small section of vvtxxl. DO NOT cut the brass tube! Take the time to be sure the parting tool is sharp, adjust the tool rest, and secure it firmly. WiLh the lathe off, rest the parting tool on the tool rest and check the alignment with the cutting mark. Maintaining a secure grip with the parting chisel ill a 90° angle to the blank, allow a 1/4" space between the chisel and Lhe blank. Turn the lathe to high speed and slowly guide the paiting chiscl to the mark. Cut only lo the brass lube and remove Lhe small band of wood up lo the bushing. Finish sanding using Abralon sanding pads. For the finish sanding, we used Abralon sanding pads which have a sponge-type surface embedded with extra-fine grits and provide a surprisingly smooth finish to the Staburlizcd blanks. Trimmed blank with brass tube showing where trimmed. Turn lhe lathe off, and breathe! Check lhe blanks and, if needed, clean up the newly exposed edge and buff. 70 • Creative Woodworks & Crafts November 2005 |

||||||||||||