Creative Woodworks & crafts 2009-04, страница 49

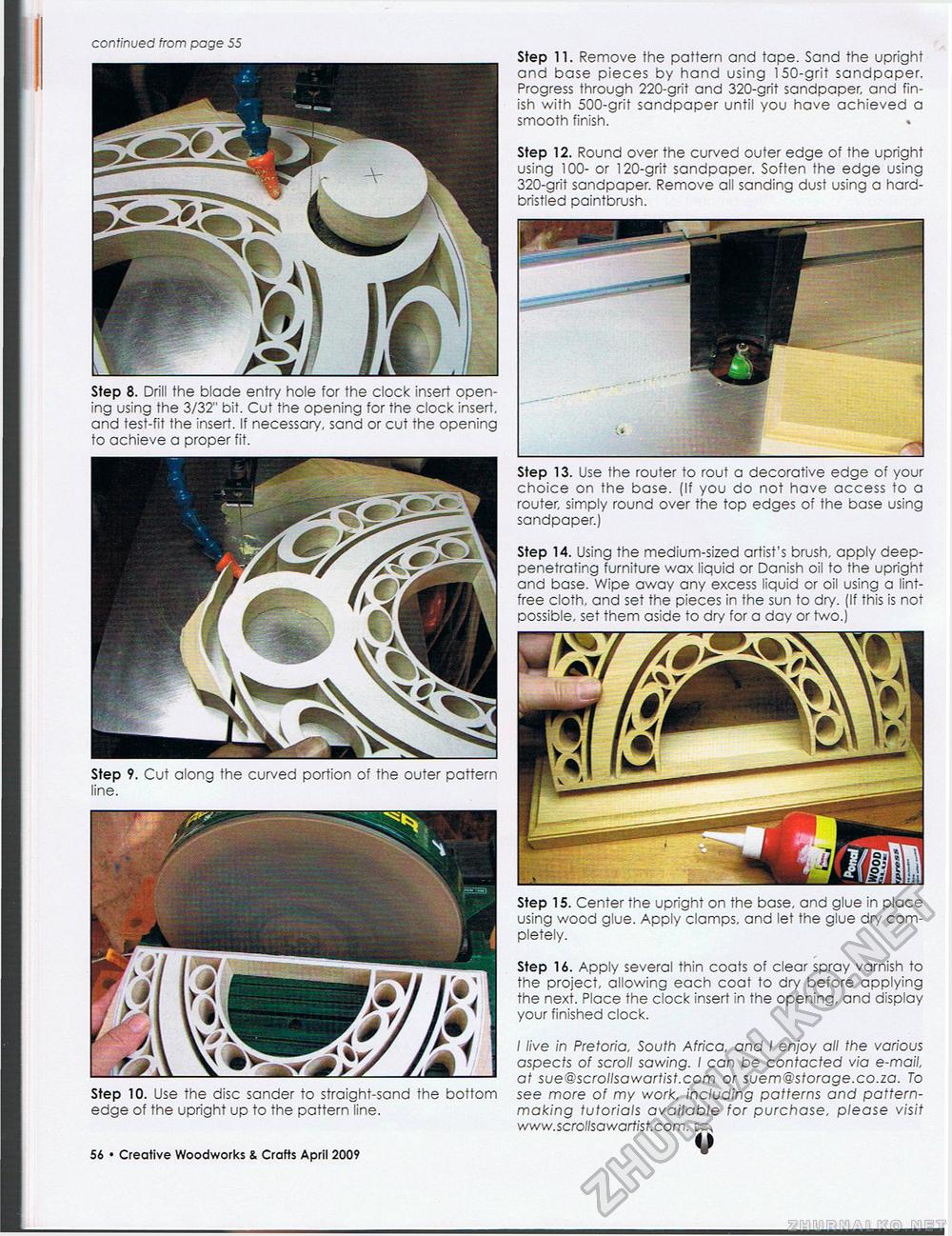

continued from page 55 Step 8. Drill the blade entry hole for the clock insert opening using the 3/32" bit. Cut the opening for the clock insert, and test-fit the insert. If necessary, sand or cut the opening to achieve a proper fit. Step 9. Cut along the curved portion of the outer pattern line. Step 10. Use the disc sander to straight-sand the bottom edge of the upright up to the pattern line. 56 • Creative Woodworks & Crafts April 2009 Step 11. Remove the pattern and tape. Sand the upright and base pieces by hand using 150-grit sandpaper. Progress through 220-grit and 320-grit sandpaper, and finish with 500-grit sandpaper until you have achieved a smooth finish. » Step 12. Round over the curved outer edge of the upright using 100- or 120-grit sandpaper. Soften the edge using 320-grit sandpaper. Remove all sanding dust using a hard-bristled paintbrush. Step 13. Use the router to rout a decorative edge of your choice on the base. (If you do not have access to a router, simply round over the top edges of the base using sandpaper.) Step 14. Using the medium-sized artist's brush, apply deep-penetrating furniture wax liquid or Danish oil to the upright and base. Wipe away any excess liquid or oil using a lint-free cloth, and set the pieces in the sun to dry. (If this is not possible, set them aside to dry for a day or two.) Step 15. Center the upright on the base, and glue in place using wood glue. Apply clamps, and let the glue dry completely. Step 16. Apply several thin coats of clear spray varnish to the project, allowing each coat to dry before applying the next. Place the clock insert in the opening, and display your finished clock. I live in Pretoria, South Africa, and I enjoy all the various aspects of scroll sawing. I can be contacted via e-mail, at sue@scrollsawartist.com or suem@storage.co.za. To see more of my work, including patterns and pattern-making tutorials available for purchase, please visit www.scrollsawartist.com. cc^ V |