Creative Woodworks & Crafts-059-1998-Fall, страница 34

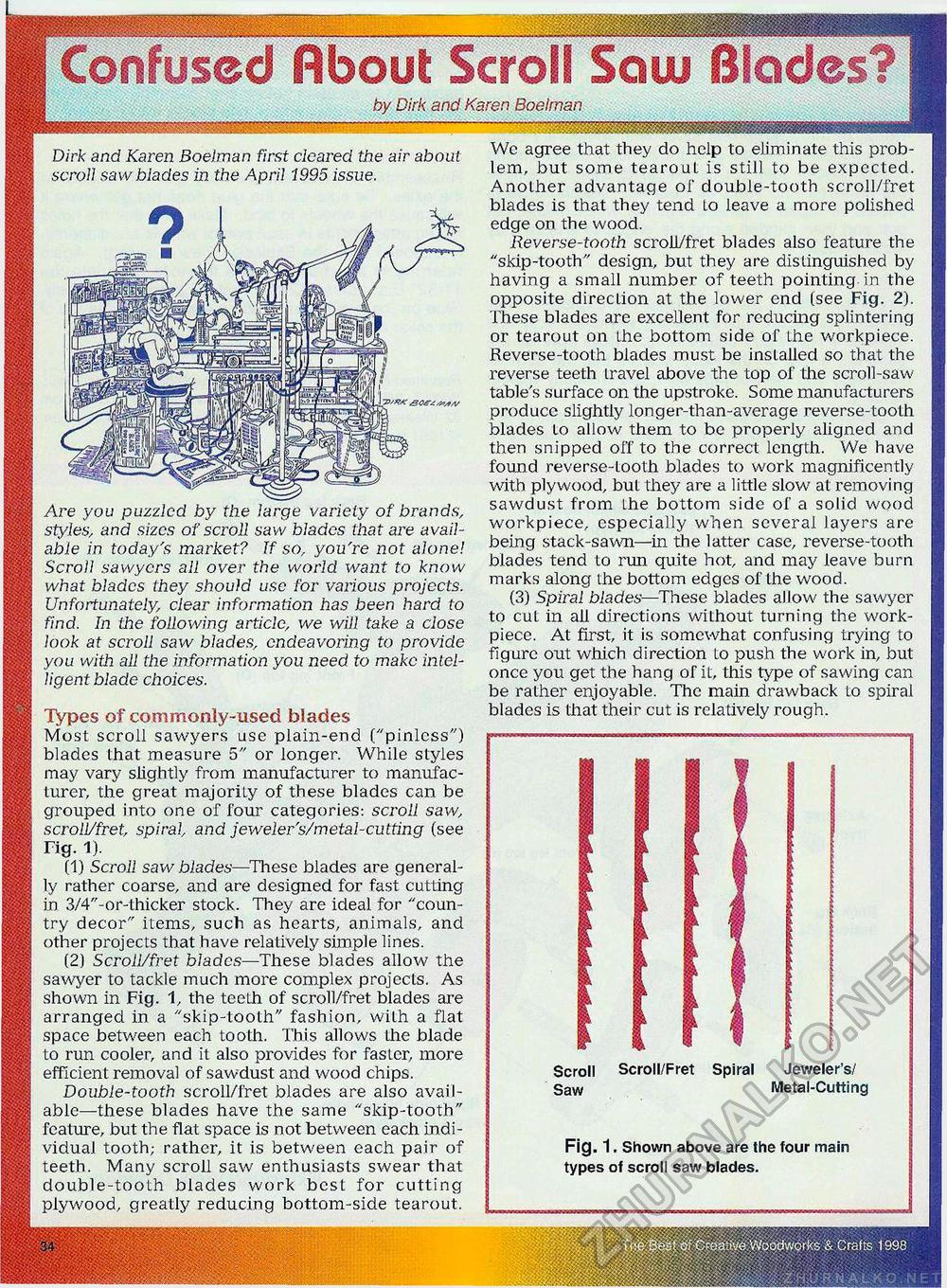

Confused About Scroll Sow Blades? by Dirk and Karen Boelman Dirk and Karen Boelman first clcared the air about scroll saw blades in the April 1995 issue. Are you puzzled by the large variety of brands, styles, and sizes of scroll saw blades that are available in today's market? Tf so, you're not alone! Scroll sawyers all over the world want to know what blades they should use for various projects. Unfortunatelyclear information has been hard to find. In the following article> we will take a close look at scroll saw blades, endeavoring to provide you with all the information you need to make intelligent blade choices. Types of commonly-used blades Most scroll sawyers use plain-end ("pinless") blades lhat measure 5" or longer. While styles may vary slightly from manufacturer to manufacturer, the great majority of these blades can be grouped into one of four categories: scroll saw, scroll/fret spiral and jeweler's/metal-cutting (see Tig. 1). (1) Scroll saw blades—These blades are generally rather coarse, and are designed for fast cutting in 3/4"-or-thicker stock. They are ideal for "country decor" items, such as hearts, animals, and other projects that have relatively simple lines. (2) Scroll/fret blades—These blades allow the sawyer to tackle much more complex projects. As shown in Fig. 1, the teeth of scroll/fret blades are arranged in a "skip-tooth" fashion, with a flat space between each tooth. This allows Lhe blade to run cooler, and it also provides for faster, more efficient removal of sawdust and wood chips. Double-tooth scroll/fret blades are also available—these blades have the same "skip-tooth" feature, but the flat space is not between each individual tooth; rather, it is between each pair of teeth. Many scroll saw enthusiasts swear that double-tooth blades work best for cutting plywood, greatly reducing bottom-side tearout. mm^mmm We agree that they do help to eliminate this problem, but some tearout is still to be expected. Another advantage of double-tooth scroll/fret blades is that they tend Lo leave a more polished edge on the wood. Reverse-tooth scroll/fret blades also feature the "skip-tooth" design, but they are distinguished by having a small number of teeth pointing in the opposite direction at the lower end (see Fig. 2). These blades are excellent for reducing splintering or tearout on Lhe bottom side of Lhe workpiece. Reverse-tooth blades must be installed so that the reverse teeth Iravei above the top of the scroll-saw table's surface on the upstroke. Some manufacturers produce slightly longer-than-average reverse-tooth blades Lo allow them to be properly aligned and then snipped off to the correct length. We have found reverse-Loolh blades to work magnificently with plywood, but they are a little slow at removing sawdust from Lhe bottom side of a solid wood workpiece, especially when several layers are being stack-sawn—in the latter case, reverse-tooth blades tend to run quite hot, and may leave burn marks along the bottom edges of the wood. (3) Spiral blades—These blades allow the sawyer to cuL in all directions without turning the work-piece. At first, it is somewhat confusing trying to figure out which direction Lo push the work in, but once you get the hang of it, this type of sawing can be rather enjoyable. The main drawback Lo spiral blades is that their cut is relatively rough. Scroll Scroll/Fret Spiral Jeweler's/ Saw Metal-Cutting Fig. 1. Shown above are the four main types of scroll saw blades. |