Creative Woodworks & Crafts-059-1998-Fall, страница 36

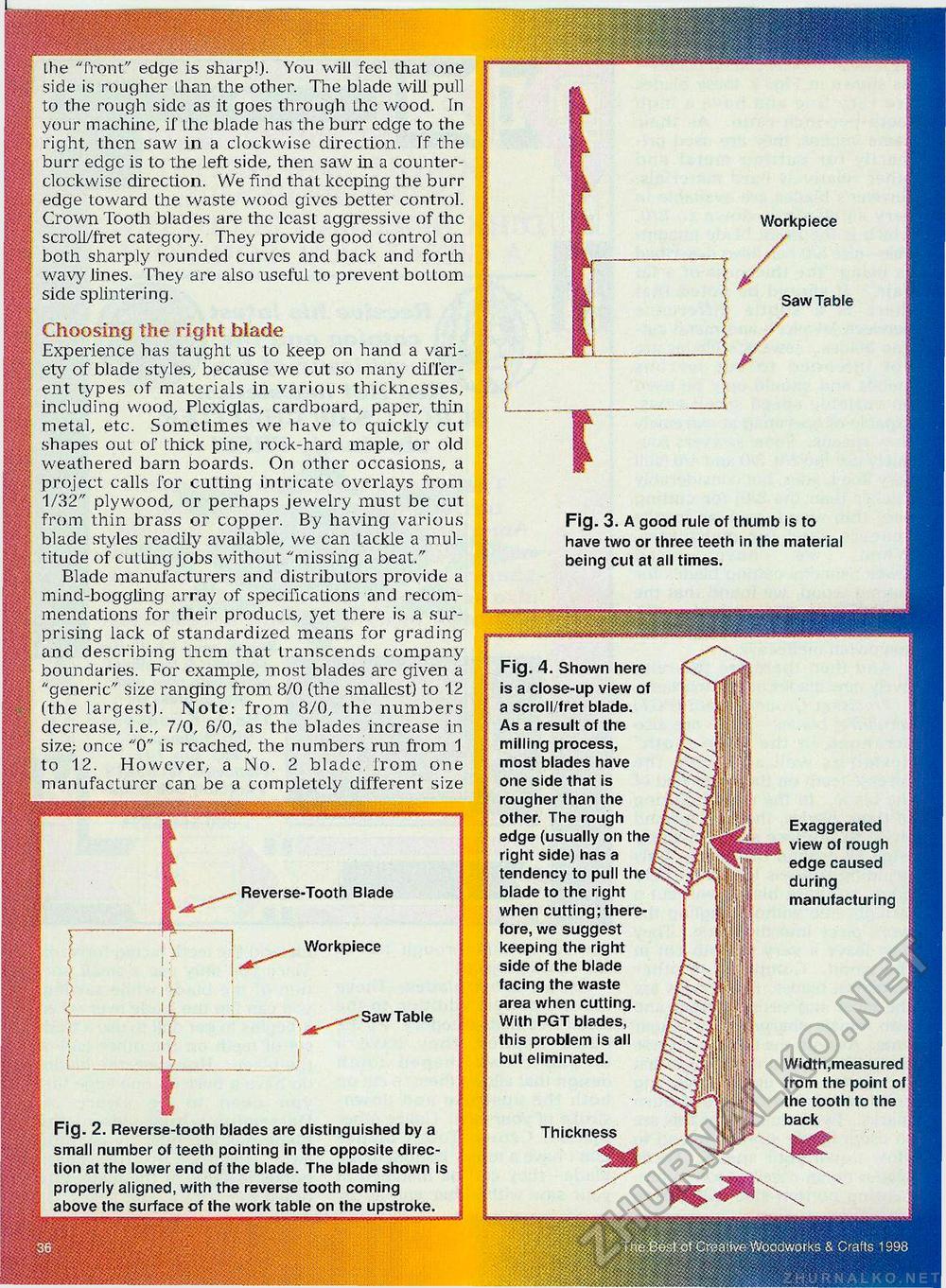

Reverse-Tooth Blade Workpiece Choosing the right blade Experience has taught us to keep on hand a variety of blade styles, because we cut so many different types of materials in various thicknesses, including wood, Plexiglas, cardboard, paper, thin metal, etc. Sometimes we have to quickly cut shapes out of thick pine, rock-hard maple, or old weathered barn boards. On other occasions, a project calls for cutting intricate overlays from 1/32" plywood, or perhaps jewelry must be cut from thin brass or copper. By having various blade styles readily available, we can tackle a multitude of culling jobs without "missing a beat." Blade manufacturers and distributors provide a mind-boggling array of specifications and recommendations for their products, yet there is a surprising lack of standardized means for grading and describing them that transcends company boundaries. For example, most blades are given a "generic" size ranging from 8/0 (the smallest) to 12 (the largest). Note: from 8/0, the numbers decrease, i.e., 7/0, 6/0, as the blades increase in size; once "0" is reached, the numbers run from 1 to 12. However, a No. 2 blade, from one manufacturer can be a completely different size Lhe "front" edge is sharp!). You will feel that one side is rougher than the other. The blade will pull to the rough side as it goes through the wood. In your machine, if lhe blade has the burr edge to the right, then saw in a clockwise direction. If the burr edge is to the left side, then saw in a counterclockwise direction. We find that keeping the burr edge toward the waste wood gives better control. Crown Tooth blades are the least aggressive of the scroll/fret category. They provide good control on both sharply rounded curves and back and forth wavy lines. They are also useful to prevent bolLom side splintering. -Saw Table Fig. 2. Reverse-tooth blades are distinguished by a small number of teeth pointing in the opposite direction at the lower end of the blade. The blade shown is properly aligned, with the reverse tooth coming above the surface of the work table on the upstroke. ^Il, jlll jlllMl.i l .III.,I I I....... Fig. 3. A good rule of thumb is to have two or three teeth in the material being cut at all times. Workpiece / Saw Table Fig. 4. Shown here is a close-up view of a scroll/fret blade. As a result of the milling process, most blades have one side that is rougher than the other. The rough edge (usually on the right side) has a tendency to pull the blade to the right when cutting; therefore, we suggest keeping the right side of the blade facing the waste area when cutting. With PGT blades, this problem is all but eliminated. Thickness Exaggerated view of rough edge caused during manufacturing Width,measured j from the point of j the tooth to the back |