Popular Woodworking 2000-01 № 112, страница 33

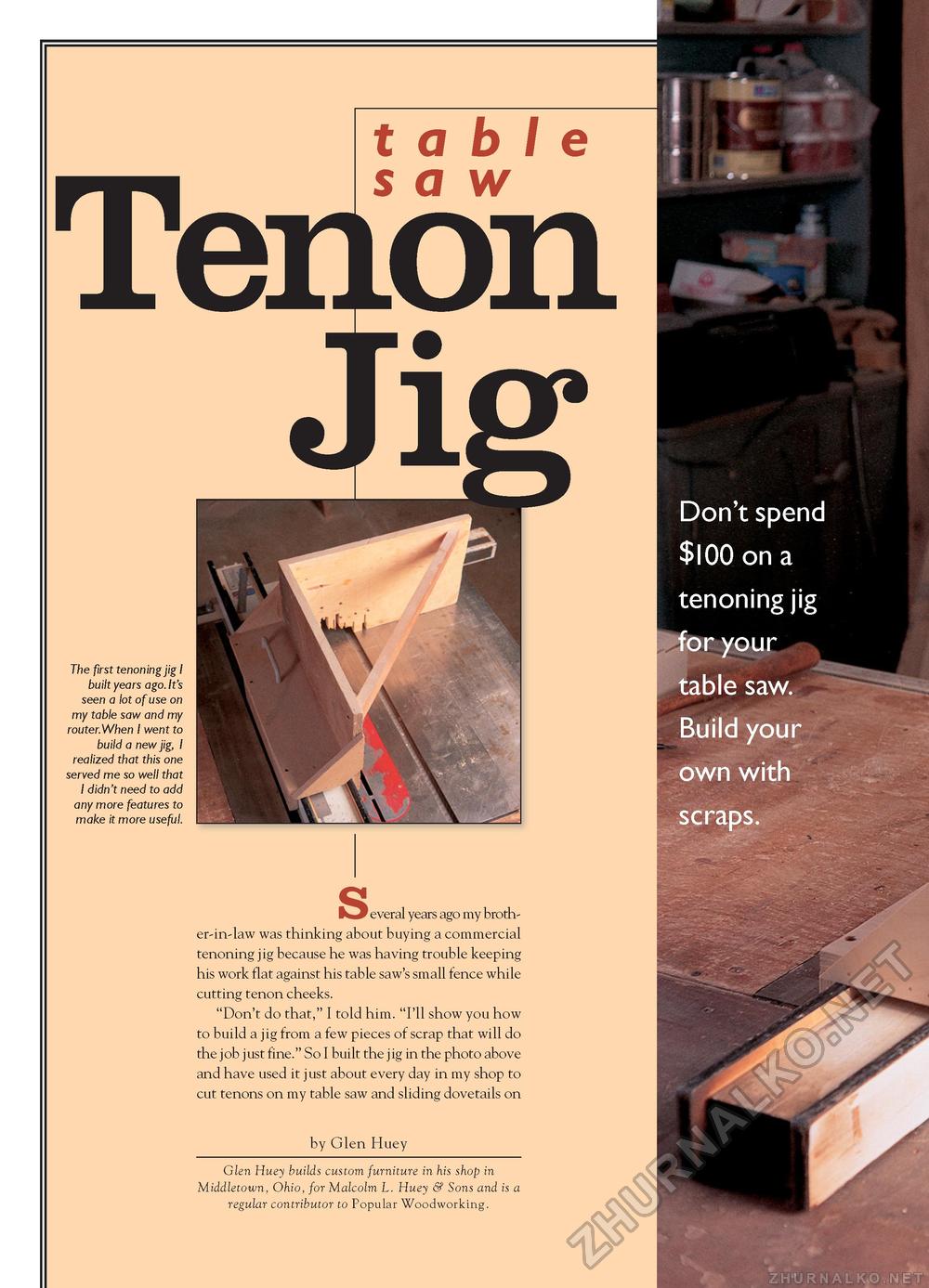

table The first tenoning jig I built years ago. It's seen a lot of use on my table saw and my router.When I went to build a new jig, I realized that this one served me so well that I didn't need to add any more features to make it more useful. everal years ago my brother-in-law was thinking about buying a commercial tenoning jig because he was having trouble keeping his work flat against his table saw's small fence while cutting tenon cheeks. "Don't do that," I told him. "I'll show you how to build a jig from a few pieces of scrap that will do the job just fine." So I built the jig in the photo above and have used it just about every day in my shop to cut tenons on my table saw and sliding dovetails on by Glen Huey Glen Huey builds custom furniture in his shop in Middletown, Ohio, for Malcolm L. Huey & Sons and is a regular contributor to Popular Woodworking. Don't spend $100 on a tenoning jig for your table saw. Build your own with scraps. |