Popular Woodworking 2000-04 № 114, страница 54

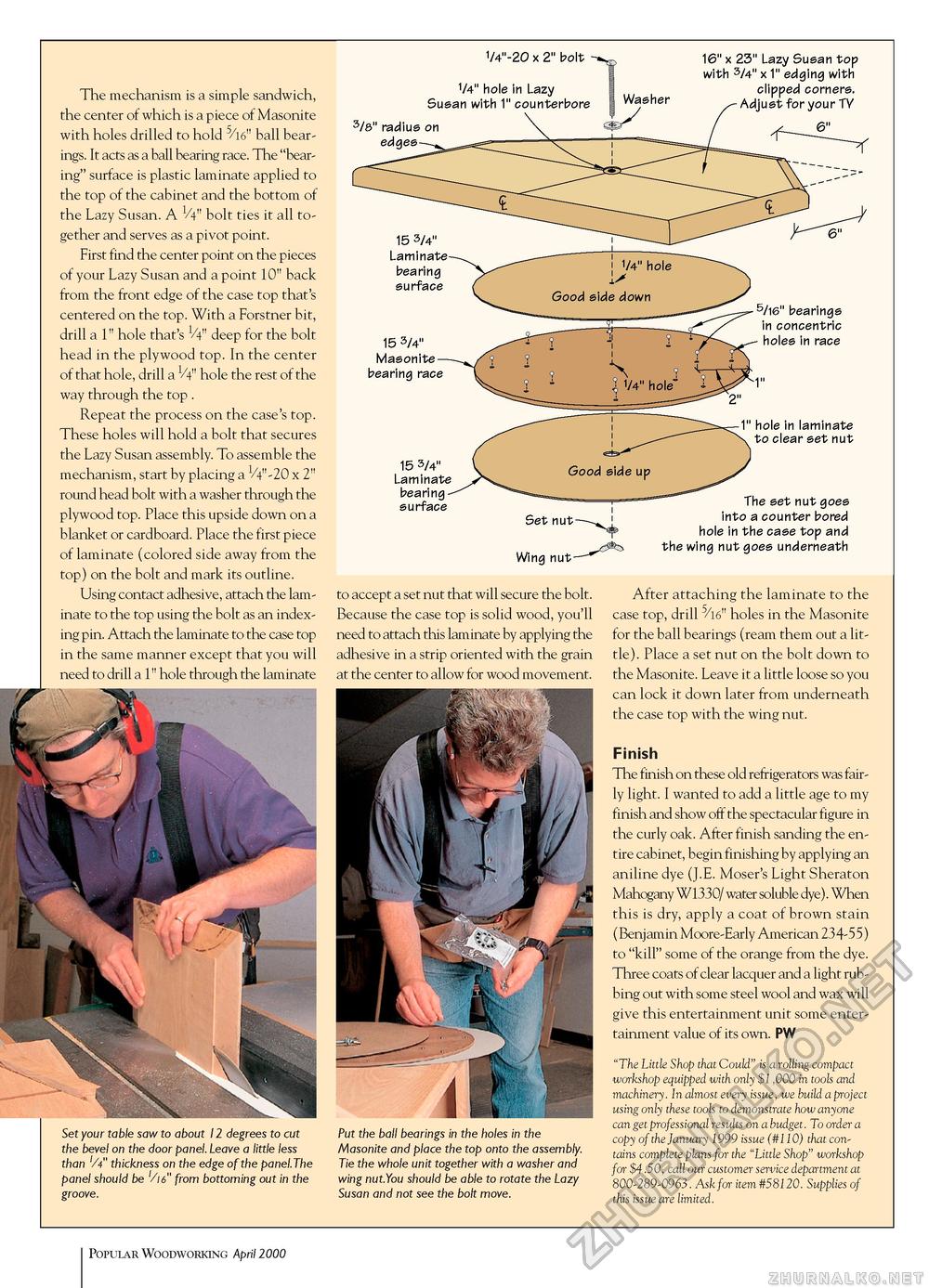

The mechanism is a simple sandwich, the center of which is a piece of Masonite with holes drilled to hold 5/16" ball bearings. It acts as a ball bearing race. The "bearing" surface is plastic laminate applied to the top of the cabinet and the bottom of the Lazy Susan. A V4" bolt ties it all together and serves as a pivot point. First find the center point on the pieces of your Lazy Susan and a point 10" back from the front edge of the case top that's centered on the top. With a Forstner bit, drill a 1" hole that's V4" deep for the bolt head in the plywood top. In the center of that hole, drill a V4" hole the rest of the way through the top . Repeat the process on the case's top. These holes will hold a bolt that secures the Lazy Susan assembly. To assemble the mechanism, start by placing a V4"-20 x 2" round head bolt with a washer through the plywood top. Place this upside down on a blanket or cardboard. Place the first piece of laminate (colored side away from the top) on the bolt and mark its outline. Using contact adhesive, attach the laminate to the top using the bolt as an indexing pin. Attach the laminate to the case top in the same manner except that you will need to drill a 1" hole through the laminate 1/4"-20 x 2" bolt 1/4" hole in Lazy Susan with 1" counterbore 16" x 23" Lazy Susan top with 3/4" x 1" edging with clipped corners. Adjust for your TV 3/8" radius on edges 15 3/4" Masonite bearing race 15 3/4" Laminate bearing surface Set nut Wing nut to accept a set nut that will secure the bolt. Because the case top is solid wood, you'll need to attach this laminate by applying the adhesive in a strip oriented with the grain at the center to allow for wood movement. 1" hole in laminate to clear set nut The set nut goes into a counter bored hole in the case top and the wing nut goes underneath Set your table saw to about 12 degrees to cut the bevel on the door panel. Leave a little less than '/i" thickness on the edge of the panel.The panel should be '/is" from bottoming out in the groove. Put the ball bearings in the holes in the Masonite and place the top onto the assembly. Tie the whole unit together with a washer and wing nut.You should be able to rotate the Lazy Susan and not see the bolt move. After attaching the laminate to the case top, drill 5/16" holes in the Masonite for the ball bearings (ream them out a little). Place a set nut on the bolt down to the Masonite. Leave it a little loose so you can lock it down later from underneath the case top with the wing nut. Finish The finish on these old refrigerators was fairly light. I wanted to add a little age to my finish and show off the spectacular figure in the curly oak. After finish sanding the entire cabinet, begin finishing by applying an aniline dye (J.E. Moser's Light Sheraton Mahogany W1330/ water soluble dye). When this is dry, apply a coat of brown stain (Benjamin Moore-Early American 234-55) to "kill" some of the orange from the dye. Three coats of clear lacquer and a light rubbing out with some steel wool and wax will give this entertainment unit some entertainment value of its own. PW "The Little Shop that Could" is a rolling compact workshop equipped with only $1,000 in tools and machinery. In almost every issue, we build a project using only these tools to demonstrate how anyone can get professional results on a budget. To order a copy of the January 1999 issue (#110) that contains complete plans for the "Little Shop" workshop for $4.50, call our customer service department at 800-289-0963. Ask for item #58120. Supplies of this issue are limited. 12 Popular Woodworking April 2000 |