Popular Woodworking 2001-02 № 120, страница 12

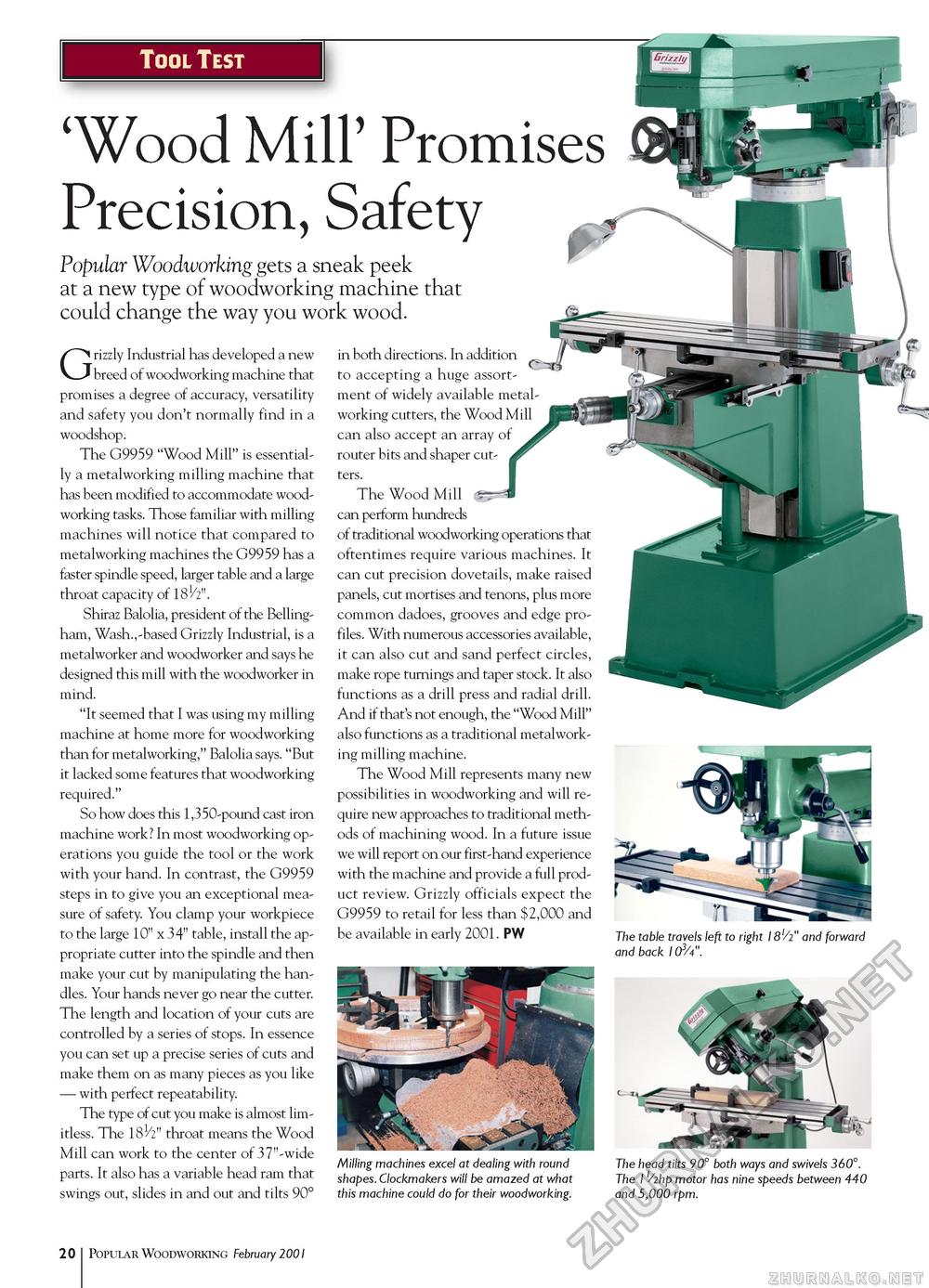

Tool Test 'Wood Mill' Promises Precision, Safety Popular Woodworking gets a sneak peek at a new type of woodworking machine that could change the way you work wood. Gr b < rizzly Industrial has developed a new ' breed of woodworking machine that promises a degree of accuracy, versatility and safety you don't normally find in a woodshop. The G9959 "Wood Mill" is essentially a metalworking milling machine that has been modified to accommodate woodworking tasks. Those familiar with milling machines will notice that compared to metalworking machines the G9959 has a faster spindle speed, larger table and a large throat capacity of 181/2". Shiraz Balolia, president of the Belling-ham, Wash.,-based Grizzly Industrial, is a metalworker and woodworker and says he designed this mill with the woodworker in mind. "It seemed that I was using my milling machine at home more for woodworking than for metalworking," Balolia says. "But it lacked some features that woodworking required." So how does this 1,350-pound cast iron machine work? In most woodworking operations you guide the tool or the work with your hand. In contrast, the G9959 steps in to give you an exceptional measure of safety. You clamp your workpiece to the large 10" x 34" table, install the appropriate cutter into the spindle and then make your cut by manipulating the handles. Your hands never go near the cutter. The length and location of your cuts are controlled by a series of stops. In essence you can set up a precise series of cuts and make them on as many pieces as you like — with perfect repeatability. The type of cut you make is almost limitless. The 181/2" throat means the Wood Mill can work to the center of 37"-wide parts. It also has a variable head ram that swings out, slides in and out and tilts 90° in both directions. In addition to accepting a huge assortment of widely available metal working cutters, the Wood Mill can also accept an array of router bits and shaper cutters. The Wood Mill can perf orm hundreds of traditional woodworking operations that oftentimes require various machines. It can cut precision dovetails, make raised panels, cut mortises and tenons, plus more common dadoes, grooves and edge profiles. With numerous accessories available, it can also cut and sand perfect circles, make rope turnings and taper stock. It also functions as a drill press and radial drill. And if that's not enough, the "Wood Mill" also functions as a traditional metalwork-ing milling machine. The Wood Mill represents many new possibilities in woodworking and will require new approaches to traditional methods of machining wood. In a future issue we will report on our first-hand experience with the machine and provide a full product review. Grizzly officials expect the G9959 to retail for less than $2,000 and be available in early 2001. PW The table travels left to right !8'/2" and forward and back 10/4". Milling machines excel at dealing with round shapes. Clockmakers will be amazed at what this machine could do for their woodworking. The head tilts 90° both ways and swivels 360°. The 1 '/2hp motor has nine speeds between 440 and 5,000 rpm. 20 Popular Woodworking February 2001 |