Popular Woodworking 2001-02 № 120, страница 14

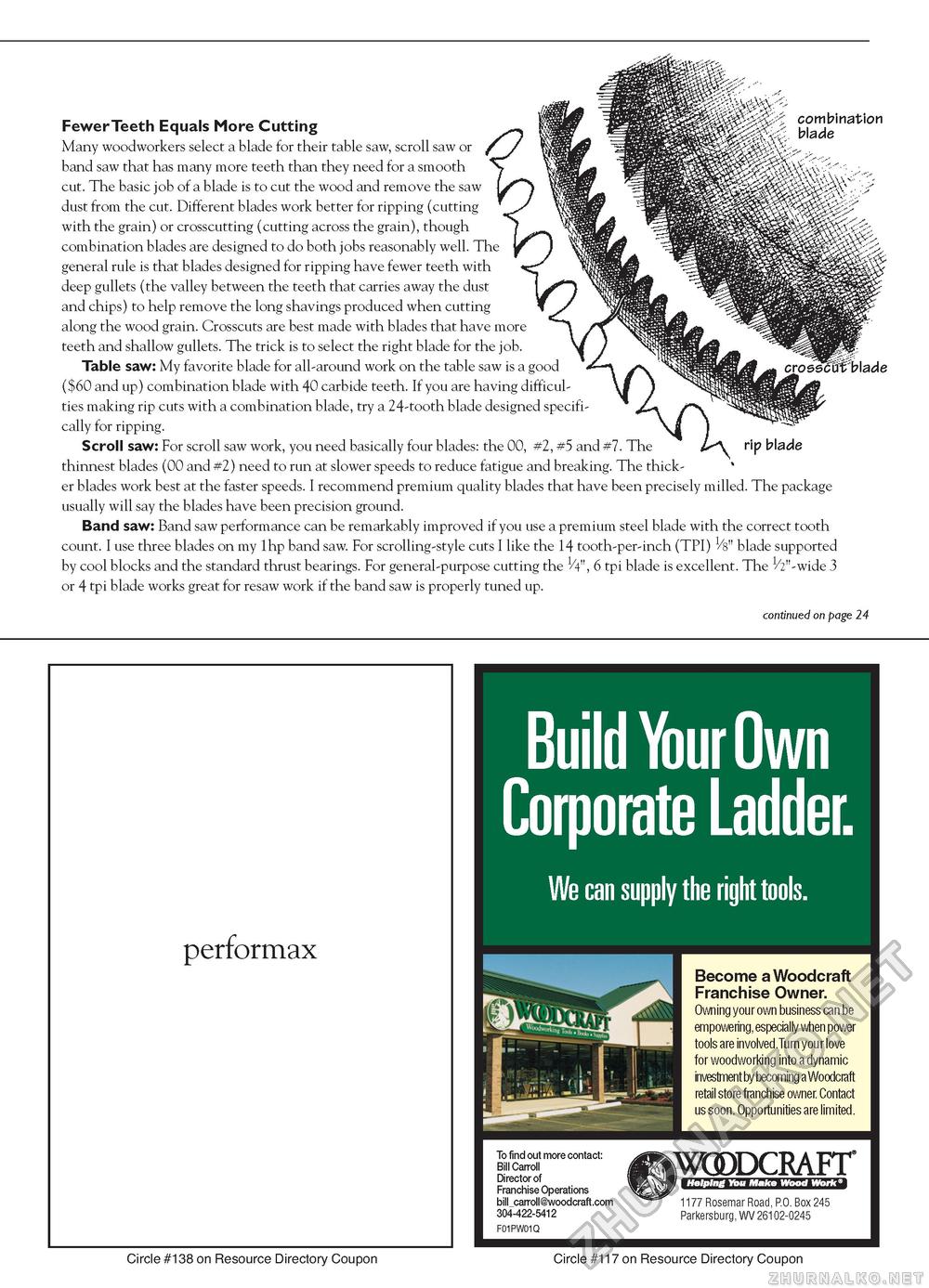

FewerTeeth Equals More Cutting Many woodworkers select a blade for their table saw, scroll saw or band saw that has many more teeth than they need for a smooth cut. The basic job of a blade is to cut the wood and remove the saw dust from the cut. Different blades work better for ripping (cutting with the grain) or crosscutting (cutting across the grain), though combination blades are designed to do both jobs reasonably well. The general rule is that blades designed for ripping have fewer teeth with deep gullets (the valley between the teeth that carries away the dust and chips) to help remove the long shavings produced when cutting along the wood grain. Crosscuts are best made with blades that have more teeth and shallow gullets. The trick is to select the right blade for the job. Table saw: My favorite blade for all-around work on the table saw is a good ($60 and up) combination blade with 40 carbide teeth. If you are having difficulties making rip cuts with a combination blade, try a 24-tooth blade designed specifi cally for ripping. Scroll saw: For scroll saw work, you need basically four blades: the 00, #2, #5 and #7. The thinnest blades (00 and #2) need to run at slower speeds to reduce fatigue and breaking. The thick er blades work best at the faster speeds. I recommend premium quality blades that have been precisely milled. The package usually will say the blades have been precision ground. Band saw: Band saw performance can be remarkably improved if you use a premium steel blade with the correct tooth count. I use three blades on my 1hp band saw. For scrolling-style cuts I like the 14 tooth-per- inch (TPI) Vs" blade supported by cool blocks and the standard thrust bearings. For general-purpose cutting the 1/4", 6 tpi blade is excellent. The 1/2"-wide 3 or 4 tpi blade works great for resaw work if the band saw is properly tuned up. combination blade rip blade continued on page 24 performax Build Your Own Corporate Ladder. We can supply the right tools. To find out more contact: Bill Carroll Director of Franchise Operations 304-422-5412 F01PW01Q Become a Woodcraft Franchise Owner. Owning your own business can be empowering, especially when power tools are involved.Turn your love for woodworking into a dynamic investment by becoming a Woodcraft retail store franchise owner. Contact us soon. Opportunities are limited. WOODCRAFT ■■fln/T.1',-to/to— ixzza 1177 Rosemar Road, P.O. Box 245 Parkersburg, WV 26102-0245 Circle #138 on Resource Directory Coupon Circle #117 on Resource Directory Coupon |