Popular Woodworking 2001-02 № 120, страница 17

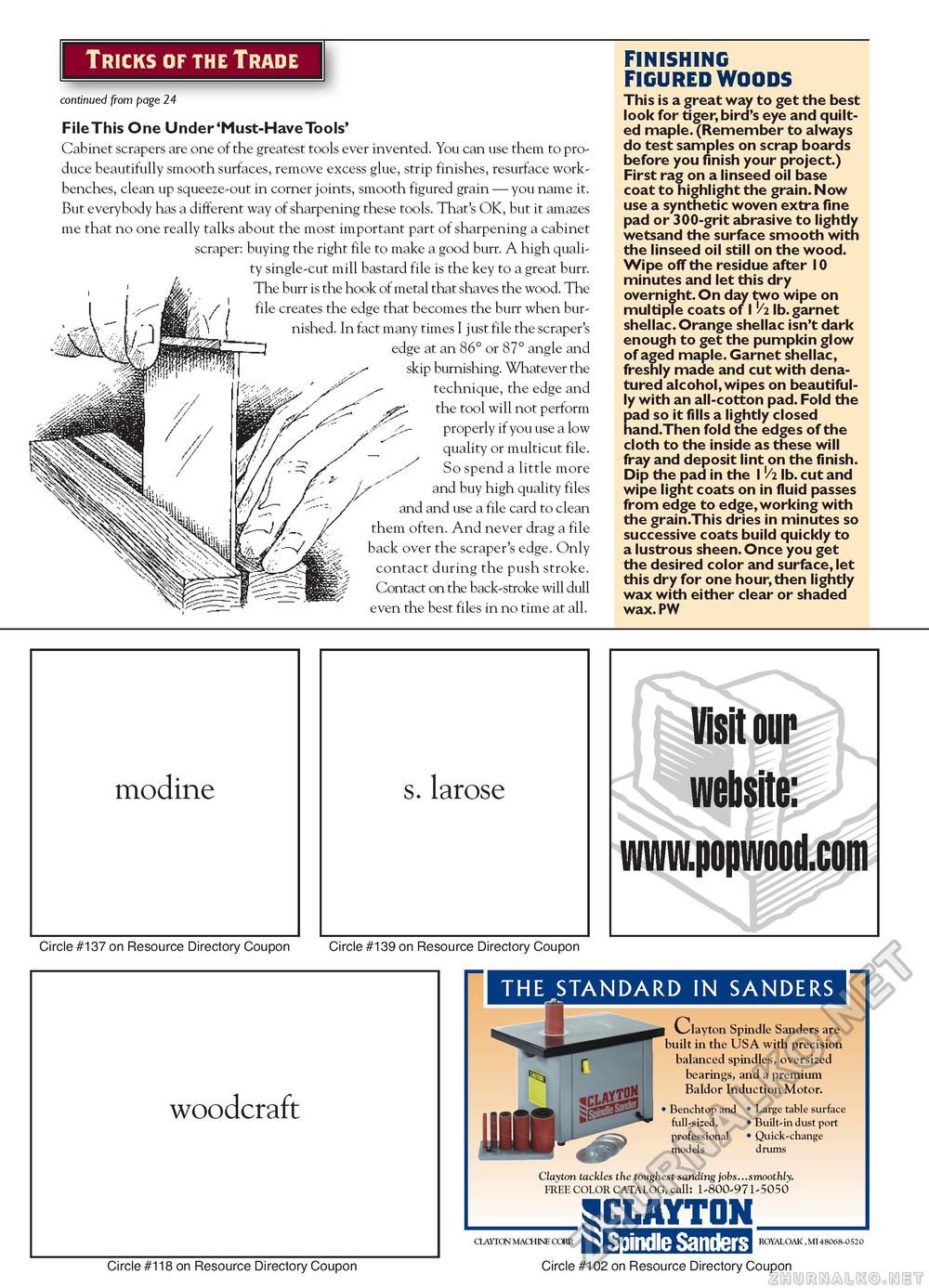

Tricks of the Trade r continued from page 24 File This One Under 'Must-Have Tools' Cabinet scrapers are one of the greatest tools ever invented. You can use them to produce beautifully smooth surfaces, remove excess glue, strip finishes, resurface workbenches, clean up squeeze-out in corner joints, smooth figured grain — you name it. But everybody has a different way of sharpening these tools. That's OK, but it amazes me that no one really talks about the most important part of sharpening a cabinet scraper: buying the right file to make a good burr. A high quality single-cut mill bastard file is the key to a great burr. The burr is the hook of metal that shaves the wood. The f I file creates the edge that becomes the burr when burnished. In fact many times I just file the scraper's edge at an 86° or 87° angle and skip burnishing. Whatever the technique, the edge and the tool will not perform properly if you use a low quality or multicut file. So spend a little more and buy high quality files and and use a file card to clean them often. And never drag a file back over the scraper's edge. Only contact during the push stroke. Contact on the back-stroke will dull even the best files in no time at all. Finishing Figured Woods This is a great way to get the best look for tiger, bird's eye and quilted maple. (Remember to always do test samples on scrap boards before you finish your project.) First rag on a linseed oil base coat to highlight the grain. Now use a synthetic woven extra fine pad or 300-grit abrasive to lightly wetsand the surface smooth with the linseed oil still on the wood. Wipe off the residue after 10 minutes and let this dry overnight. On day two wipe on multiple coats of 1 '/2 lb. garnet shellac. Orange shellac isn't dark enough to get the pumpkin glow of aged maple. Garnet shellac, freshly made and cut with denatured alcohol, wipes on beautifully with an all-cotton pad. Fold the pad so it fills a lightly closed hand.Then fold the edges of the cloth to the inside as these will fray and deposit lint on the finish. Dip the pad in the 1 '/2 lb. cut and wipe light coats on in fluid passes from edge to edge, working with the grain.This dries in minutes so successive coats build quickly to a lustrous sheen. Once you get the desired color and surface, let this dry for one hour, then lightly wax with either clear or shaded wax. PW Circle #137 on Resource Directory Coupon Circle #139 on Resource Directory Coupon THE STANDARD IN SANDERS Clayton Spindle Sanders are built in the USA with precision balanced spindles, oversized bearings, and a premium Baldor Induction Motor. Benchtop and full-sized, professional models ► Large table surface Built-in dust port Quick-change drums CLAYTON MACHINE CCRE Circle #118 on Resource Directory Coupon Clayton tackles the toughest sanding jobs...smoothly. free color catalog, call: 1-800-971-5050 clcCLAYT0N Circle #102 on Resource Directory Coupon ROYALOAK, MI48068-0520 |