Popular Woodworking 2001-02 № 120, страница 25

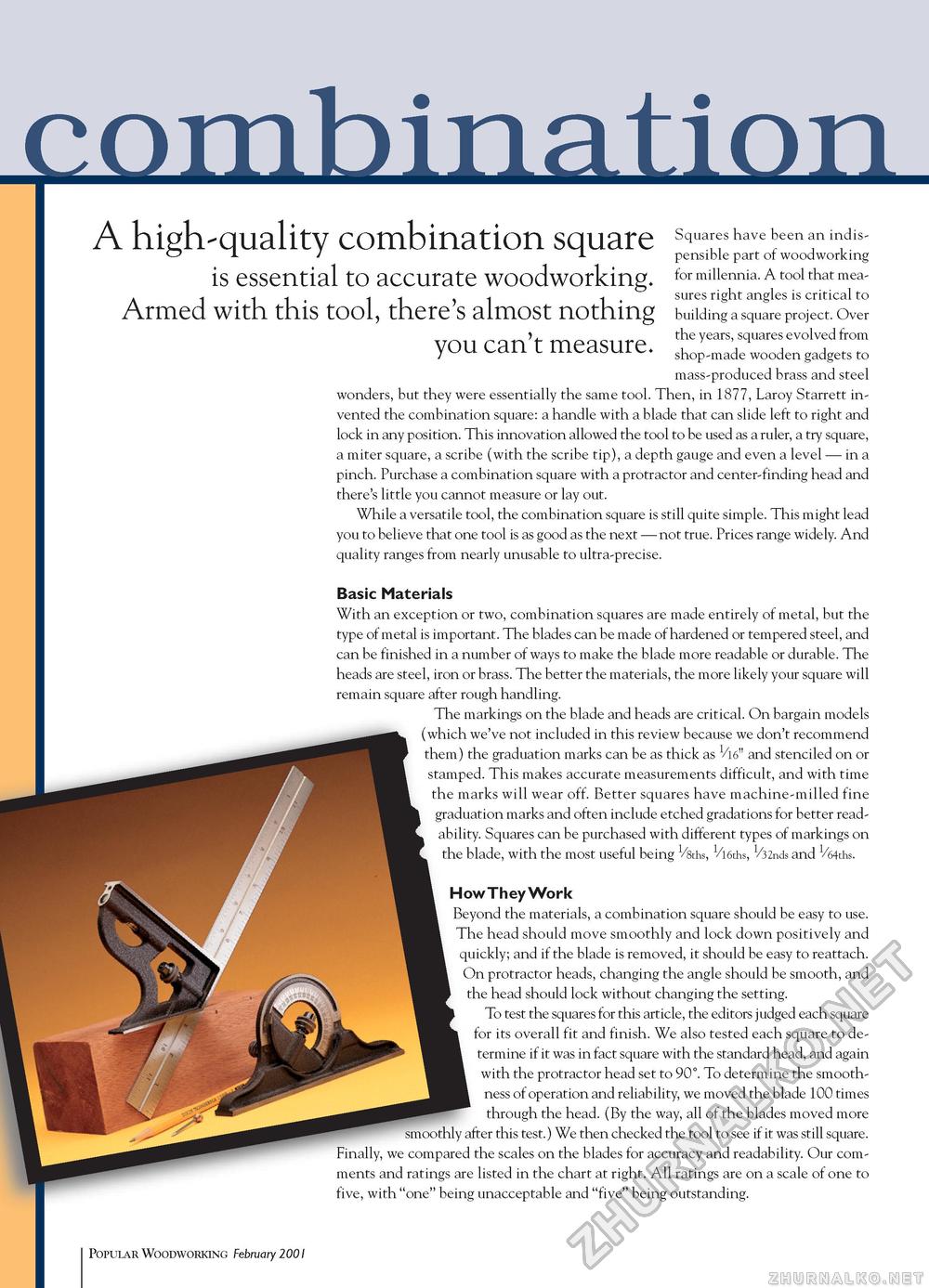

A high-quality combination square is essential to accurate woodworking. Squares have been an indis-pensible part of woodworking for millennia. A tool that measures right angles is critical to Armed with this tool, there s almost nothing building a square project. Over the years, squares evolved from you can t measure. shop-madewood en gadgets to mass-produced brass and steel wonders, but they were essentially the same tool. Then, in 1877, Laroy Starrett invented the combination square: a handle with a blade that can slide left to right and lock in any position. This innovation allowed the tool to be used as a ruler, a try square, a miter square, a scribe (with the scribe tip), a depth gauge and even a level — in a pinch. Purchase a combination square with a protractor and center-finding head and there's little you cannot measure or lay out. While a versatile tool, the combination square is still quite simple. This might lead you to believe that one tool is as good as the next — not true. Prices range widely. And quality ranges from nearly unusable to ultra-precise. Basic Materials With an exception or two, combination squares are made entirely of metal, but the type of metal is important. The blades can be made of hardened or tempered steel, and can be finished in a number of ways to make the blade more readable or durable. The heads are steel, iron or brass. The better the materials, the more likely your square will remain square after rough handling. The markings on the blade and heads are critical. On bargain models (which we've not included in this review because we don't recommend them) the graduation marks can be as thick as and stenciled on or stamped. This makes accurate measurements difficult, and with time the marks will wear off. Better squares have machine-milled fine graduation marks and often include etched gradations for better readability. Squares can be purchased with diff erent types of markings on the blade, with the most useful being V&hs, ^ths, 1/i2nds and V^ths. HowThey Work Beyond the materials, a combination square should be easy to use. The head should move smoothly and lock down positively and quickly; and if the blade is removed, it should be easy to reattach. On protractor heads, changing the angle should be smooth, and the head should lock without changing the setting. To test the squares for this article, the editors judged each square for its overall fit and finish. We also tested each square to determine if it was in fact square with the standard head, and again with the protractor head set to 90°. To determine the smoothness of operation and reliability, we moved the blade 100 times through the head. (By the way, all of the blades moved more smoothly after this test.) We then checked the tool to see if it was still square. Finally, we compared the scales on the blades for accuracy and readability. Our comments and ratings are listed in the chart at right. All ratings are on a scale of one to five, with "one" being unacceptable and "five" being outstanding. 25 Popular Woodworking February 2001 |