Popular Woodworking 2001-02 № 120, страница 28

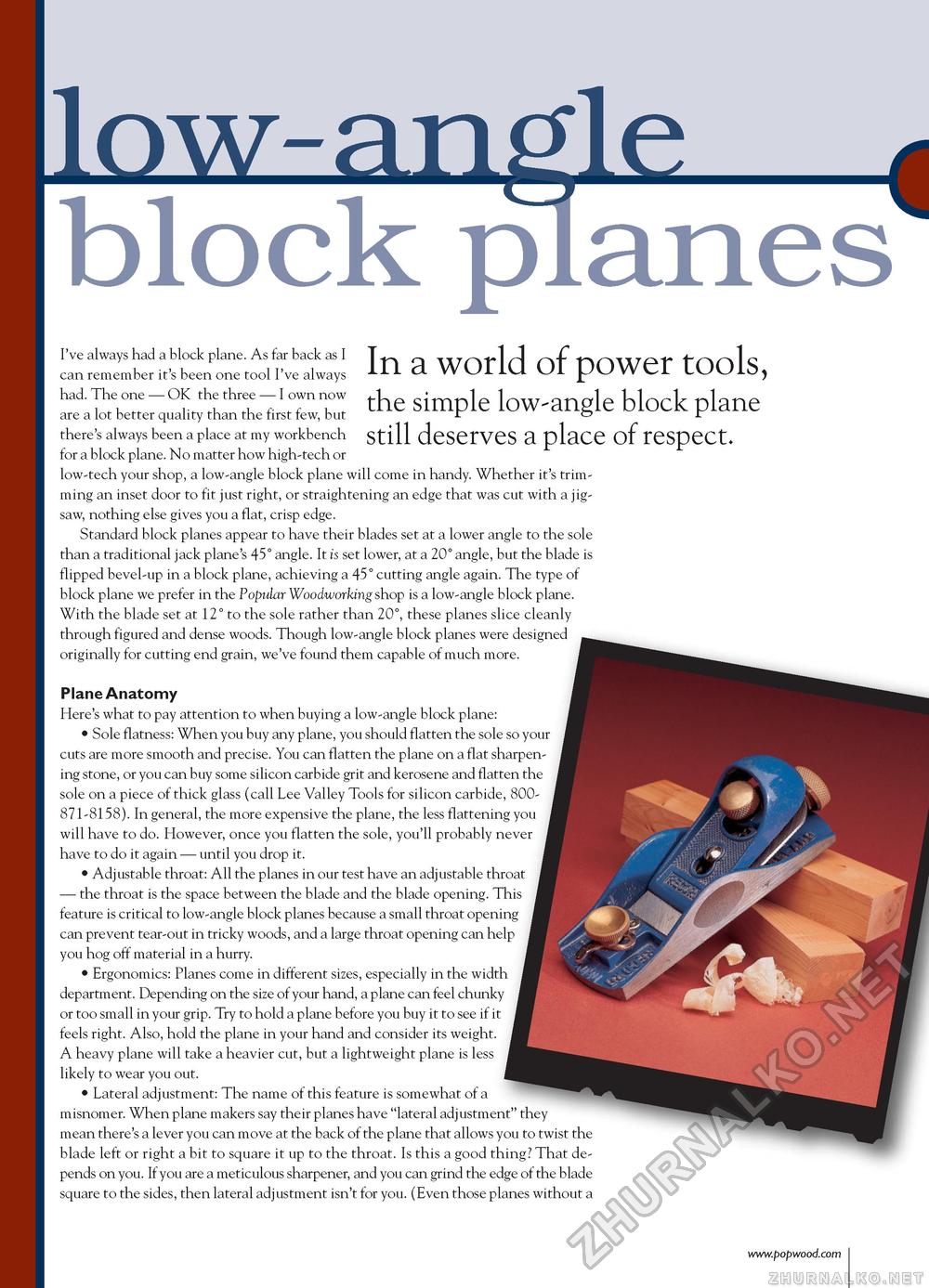

owblock planesIn a world of power tools, the simple low-angle block plane still deserves a place of respect. I've always had a block plane. As far back as I can remember it's been one tool I've always had. The one — OK the three — I own now are a lot better quality than the first few, but there's always been a place at my workbench for a block plane. No matter how high-tech or low-tech your shop, a low-angle block plane will come in handy. Whether it's trimming an inset door to fit just right, or straightening an edge that was cut with a jigsaw, nothing else gives you a flat, crisp edge. Standard block planes appear to have their blades set at a lower angle to the sole than a traditional jack plane's 45° angle. It is set lower, at a 20° angle, but the blade is flipped bevel-up in a block plane, achieving a 45° cutting angle again. The type of block plane we prefer in the Popular Woodworking shop is a low-angle block plane. With the blade set at 12° to the sole rather than 20°, these planes slice cleanly through f igured and dense woods. Though low-angle block planes were designed originally for cutting end grain, we've found them capable of much more. Plane Anatomy Here's what to pay attention to when buying a low-angle block plane: • Sole flatness: When you buy any plane, you should flatten the sole so your cuts are more smooth and precise. You can flatten the plane on a flat sharpening stone, or you can buy some silicon carbide grit and kerosene and flatten the sole on a piece of thick glass (call Lee Valley Tools for silicon carbide, 800871-8158). In general, the more expensive the plane, the less flattening you will have to do. However, once you flatten the sole, you'll probably never have to do it again — until you drop it. • Adjustable throat: All the planes in our test have an adjustable throat — the throat is the space between the blade and the blade opening. This feature is critical to low-angle block planes because a small throat opening can prevent tear-out in tricky woods, and a large throat opening can help you hog off material in a hurry. • Ergonomics: Planes come in different sizes, especially in the width department. Depending on the size of your hand, a plane can feel chunky or too small in your grip. Try to hold a plane before you buy it to see if it feels right. Also, hold the plane in your hand and consider its weight A heavy plane will take a heavier cut, but a lightweight plane is less likely to wear you out. • Lateral adjustment: The name of this feature is somewhat of a misnomer. When plane makers say their planes have "lateral adjustment" they mean there's a lever you can move at the back of the plane that allows you to twist the blade left or right a bit to square it up to the throat. Is this a good thing? That depends on you. If you are a meticulous sharpener, and you can grind the edge of the blade square to the sides, then lateral adjustment isn't for you. (Even those planes without a |