Popular Woodworking 2001-02 № 120, страница 52

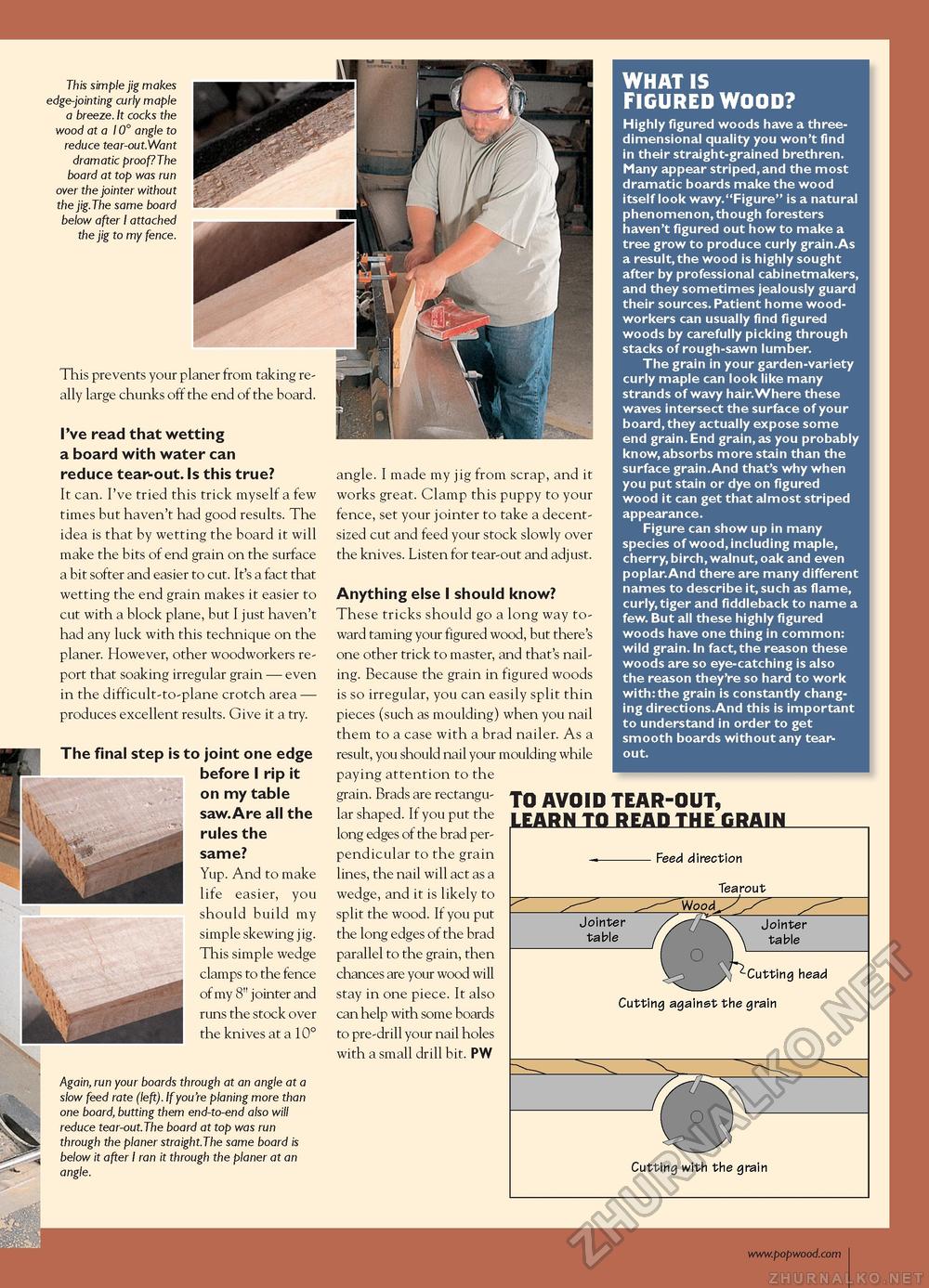

WHAT IS FIGURED WOOD? Highly figured woods have a three-dimensional quality you won't find in their straight-grained brethren. Many appear striped,and the most dramatic boards make the wood itself look wavy."Figure" is a natural phenomenon, though foresters haven't figured out how to make a tree grow to produce curly grain.As a result,the wood is highly sought after by professional cabinetmakers, and they sometimes jealously guard their sources. Patient home woodworkers can usually find figured woods by carefully picking through stacks of rough-sawn lumber. The grain in your garden-variety curly maple can look like many strands of wavy hair.Where these waves intersect the surface of your board, they actually expose some end grain. End grain, as you probably know, absorbs more stain than the surface grain.And that's why when you put stain or dye on figured wood it can get that almost striped appearance. Figure can show up in many species of wood, including maple, cherry, birch, walnut, oak and even poplar.And there are many different names to describe it, such as flame, curly,tiger and fiddleback to name a few. But all these highly figured woods have one thing in common: wild grain. In fact,the reason these woods are so eye-catching is also the reason they're so hard to work with: the grain is constantly changing directions.And this is important to understand in order to get smooth boards without any tear-out. This simple jig makes edge-jointing curly maple a breeze. It cocks the wood at a 10° angle to reduce tear-out.Want dramatic proof? The board at top was run over the jointer without the jig.The same board below after I attached the jig to my fence. This prevents your planer from taking really large chunks off the end of the board. I've read that wetting a board with water can reduce tear-out. Is this true? It can. I've tried this trick myself a few times but haven't had good results. The idea is that by wetting the board it will make the bits of end grain on the surface a bit softer and easier to cut. It's a fact that wetting the end grain makes it easier to cut with a block plane, but I just haven't had any luck with this technique on the planer. However, other woodworkers report that soaking irregular grain — even in the difficult-to-plane crotch area — produces excellent results. Give it a try. The final step is to joint one edge before I rip it on my table saw.Are all the rules the same? Yup. And to make life easier, you should build my simple skewing jig. This simple wedge clamps to the fence of my 8" jointer and runs the stock over the knives at a 10° Again, run your boards through at an angle at a slow feed rate (left). If you're planing more than one board, butting them end-to-end also will reduce tear-out.The board at top was run through the planer straight.The same board is below it after I ran it through the planer at an angle. angle. I made my jig from scrap, and it works great. Clamp this puppy to your fence, set your jointer to take a decent-sized cut and feed your stock slowly over the knives. Listen for tear-out and adjust. Anything else I should know? These tricks should go a long way toward taming your figured wood, but there's one other trick to master, and that's nailing. Because the grain in figured woods is so irregular, you can easily split thin pieces (such as moulding) when you nail them to a case with a brad nailer. As a result, you should nail your moulding while paying attention to the grain. Brads are rectangular shaped. If you put the long edges of the brad perpendicular to the grain lines, the nail will act as a wedge, and it is likely to split the wood. If you put the long edges of the brad parallel to the grain, then chances are your wood will stay in one piece. It also can help with some boards to pre-drill your nail holes with a small drill bit. PW To avoid tear-out, learn to read the grain Feed direction Tearout Jointer table Jointer table -Cutting head Cutting against the grain Cutting with the grain |