Popular Woodworking 2001-02 № 120, страница 51

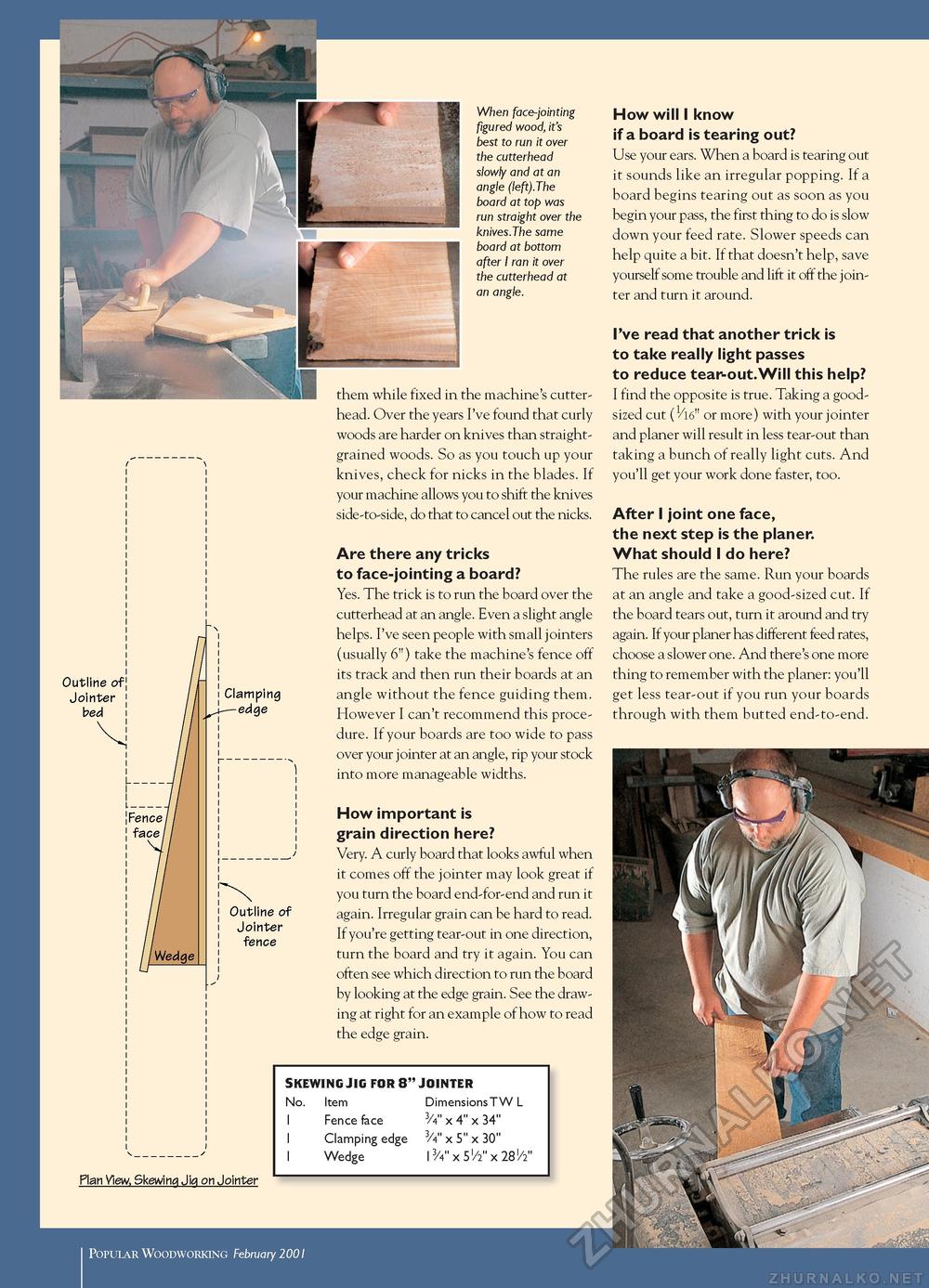

Outline of! Jointer bed Clamping ^edge Outline of Jointer fence When face-jointing figured wood, it's best to run it over the cutterhead slowly and at an angle (left).The board at top was run straight over the knives.The same board at bottom after I ran it over the cutterhead at an angle. them while fixed in the machine's cutter-head. Over the years I've found that curly woods are harder on knives than straight-grained woods. So as you touch up your knives, check for nicks in the blades. If your machine allows you to shift the knives side-to-side, do that to cancel out the nicks. Are there any tricks to face-jointing a board? Yes. The trick is to run the board over the cutterhead at an angle. Even a slight angle helps. I've seen people with small jointers (usually 6") take the machine's fence off its track and then run their boards at an angle without the fence guiding them. However I can't recommend this procedure. If your boards are too wide to pass over your jointer at an angle, rip your stock into more manageable widths. How important is grain direction here? Very. A curly board that looks awful when it comes off the jointer may look great if you turn the board end-for-end and run it again. Irregular grain can be hard to read. If you're getting tear-out in one direction, turn the board and try it again. You can often see which direction to run the board by looking at the edge grain. See the drawing at right for an example of how to read the edge grain. Plan View, Skewing Jig on Jointer

How will I know if a board is tearing out? Use your ears. When a board is tearing out it sounds like an irregular popping. If a board begins tearing out as soon as you begin your pass, the first thing to do is slow down your feed rate. Slower speeds can help quite a bit. If that doesn't help, save yourself some trouble and lift it off the jointer and turn it around. I've read that another trick is to take really light passes to reduce tear-out.Will this help? I find the opposite is true. Taking a good-sized cut (1/l6" or more) with your jointer and planer will result in less tear-out than taking a bunch of really light cuts. And you'll get your work done faster, too. After I joint one face, the next step is the planer. What should I do here? The rules are the same. Run your boards at an angle and take a good-sized cut. If the board tears out, turn it around and try again. If your planer has different feed rates, choose a slower one. And there's one more thing to remember with the planer: you'll get less tear-out if you run your boards through with them butted end-to-end. |