Popular Woodworking 2001-06 № 122, страница 17

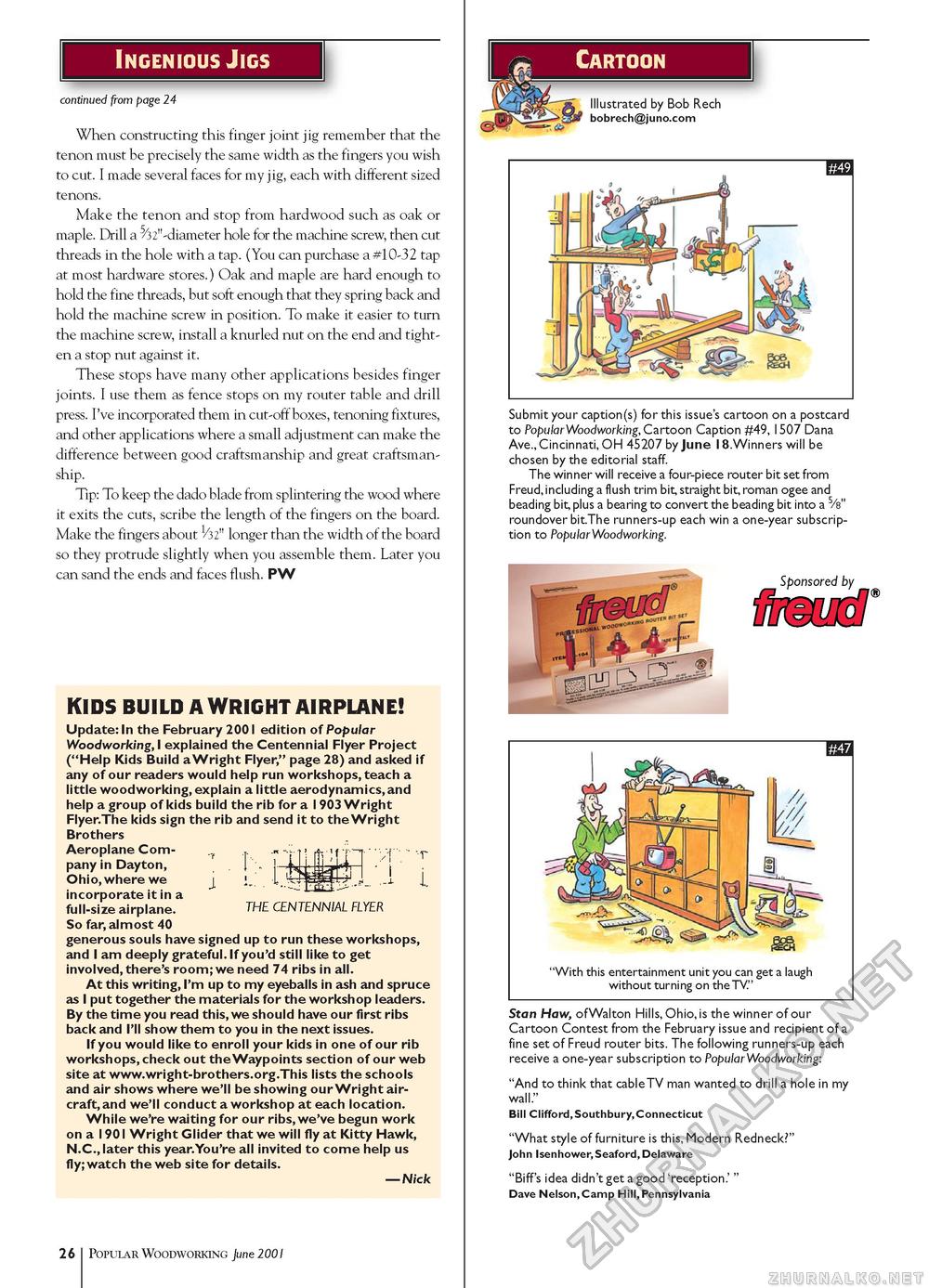

Ingenious Jigs continued from page 24 When constructing this finger joint jig remember that the tenon must be precisely the same width as the fingers you wish to cut. I made several faces for my jig, each with different sized tenons. Make the tenon and stop from hardwood such as oak or maple. Drill a ^''-diameter hole for the machine screw, then cut threads in the hole with a tap. (You can purchase a #10-32 tap at most hardware stores.) Oak and maple are hard enough to hold the fine threads, but soft enough that they spring back and hold the machine screw in position. To make it easier to turn the machine screw, install a knurled nut on the end and tighten a stop nut against it. These stops have many other applications besides finger joints. I use them as fence stops on my router table and drill press. I've incorporated them in cut-off boxes, tenoning fixtures, and other applications where a small adjustment can make the difference between good craftsmanship and great craftsmanship. Tip: To keep the dado blade from splintering the wood where it exits the cuts, scribe the length of the fingers on the board. Make the fingers about 1/32" longer than the width of the board so they protrude slightly when you assemble them. Later you can sand the ends and faces flush. PW THE CENTENNIAL FLYER KIDS BUILD A WRIGHT AIRPLANE! Update: In the February 2001 edition of Popular Woodworking,! explained the Centennial Flyer Project ("Help Kids Build a Wright Flyer," page 28) and asked if any of our readers would help run workshops, teach a little woodworking, explain a little aerodynamics, and help a group of kids build the rib for a 1903 Wright Flyer.The kids sign the rib and send it to the Wright Brothers Aeroplane Com- ... - - rfc-'f" pany in Dayton, Ohio, where we incorporate it in a full-size airplane. So far, almost 40 generous souls have signed up to run these workshops, and I am deeply grateful. If you'd still like to get involved, there's room; we need 74 ribs in all. At this writing, I'm up to my eyeballs in ash and spruce as I put together the materials for the workshop leaders. By the time you read this, we should have our first ribs back and I'll show them to you in the next issues. If you would like to enroll your kids in one of our rib workshops, check out the Waypoints section of our web site at www.wright-brothers.org.This lists the schools and air shows where we'll be showing our Wright air-craft,and we'll conduct a workshop at each location. While we're waiting for our ribs,we've begun work on a 1901 Wright Glider that we will fly at Kitty Hawk, N.C., later this year.You're all invited to come help us fly; watch the web site for details. — Nick Cartoon Illustrated by Bob Rech bobrech@juno.com 1#49 Submit your caption(s) for this issue's cartoon on a postcard to PopularWoodworking,Cartoon Caption #49, 1507 Dana Ave.,Cincinnati, OH 45207 by June l8.Winners will be chosen by the editorial staff. The winner will receive a four-piece router bit set from Freud,including a flush trim bit, straight bit,roman ogee and beading bit, plus a bearing to convert the beading bit into a 5/s" roundover bit.The runners-up each win a one-year subscription to Popular Woodworking. Sponsored by "With this entertainment unit you can get a laugh without turning on the TV." Stan Haw, ofWalton Hills, Ohio, is the winner of our Cartoon Contest from the February issue and recipient of a fine set of Freud router bits. The following runners-up each receive a one-year subscription to Popular Woodworking: "And to think that cable TV man wanted to drill a hole in my wall." Bill Clifford, Southbury, Connecticut "What style of furniture is this, Modern Redneck?" John Isenhower,Seaford, Delaware "Biff's idea didn't get a good 'reception.' " Dave Nelson, Camp Hill, Pennsylvania 26 Popular Woodworking June 2001 |