Popular Woodworking 2001-06 № 122, страница 28

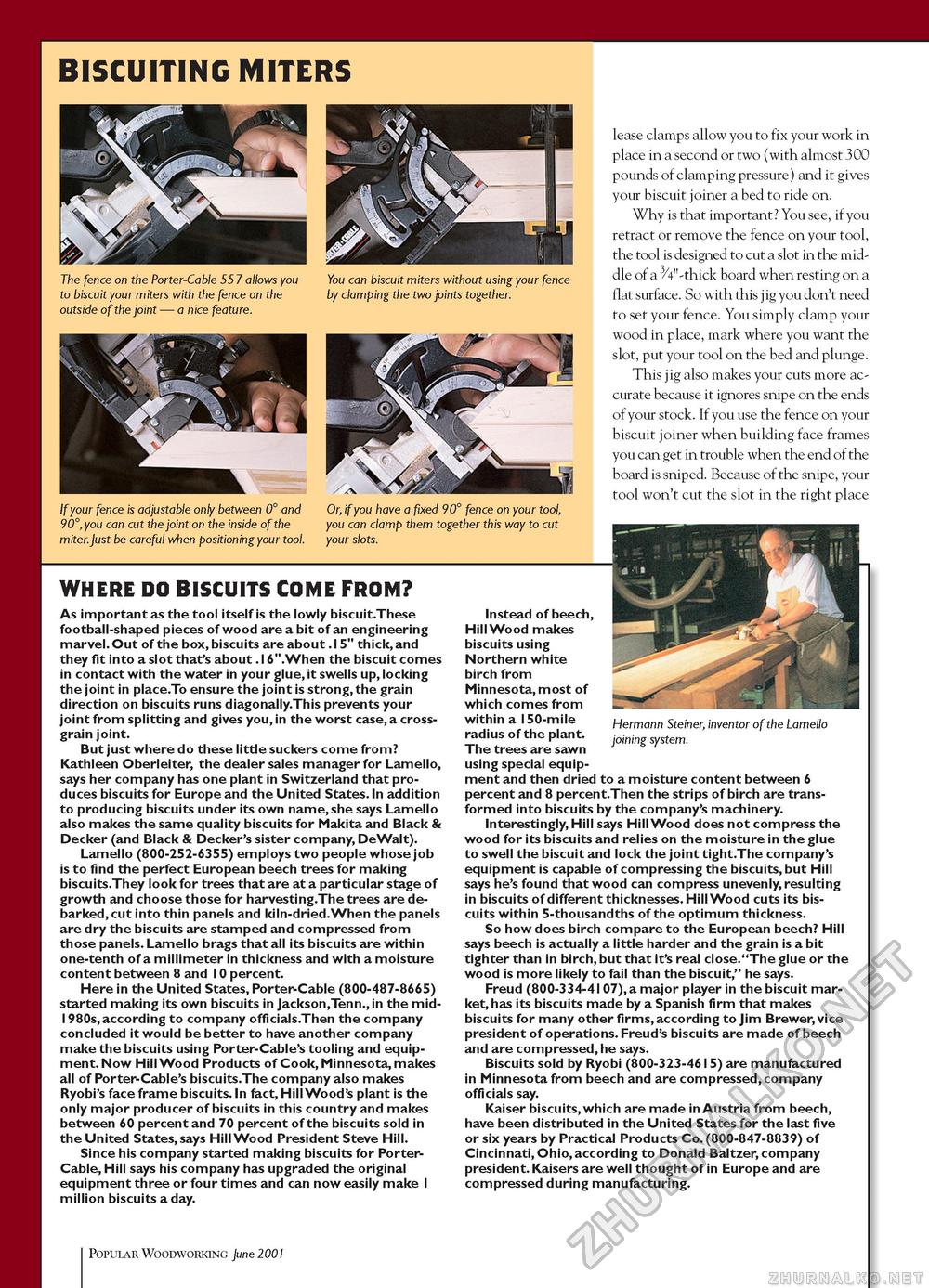

BISCUITING MITERS The fence on the Porter-Cable 557 allows you to biscuit your miters with the fence on the outside of the joint — a nice feature. You can biscuit miters without using your fence by clamping the two joints together. If your fence is adjustable only between 0° and 90°, you can cut the joint on the inside of the miter. Just be careful when positioning your tool. Or, if you have a fixed 90° fence on your tool, you can clamp them together this way to cut your slots. lease clamps allow you to fix your work in place in a second or two (with almost 300 pounds of clamping pressure) and it gives your biscuit joiner a bed to ride on. Why is that important? You see, if you retract or remove the fence on your tool, the tool is designed to cut a slot in the middle of a 3/4" -thick board when resting on a flat surface. So with this jig you don't need to set your fence. You simply clamp your wood in place, mark where you want the slot, put your tool on the bed and plunge. This jig also makes your cuts more accurate because it ignores snipe on the ends of your stock. If you use the fence on your biscuit joiner when building face frames you can get in trouble when the end of the board is sniped. Because of the snipe, your tool won't cut the slot in the right place WHERE DO BISCUITS COME FROM? As important as the tool itself is the lowly biscuit.These football-shaped pieces of wood are a bit of an engineering marvel. Out of the box, biscuits are about .15" thick, and they fit into a slot that's about .16".When the biscuit comes in contact with the water in your glue, it swells up, locking the joint in place.To ensure the joint is strong, the grain direction on biscuits runs diagonally.This prevents your joint from splitting and gives you, in the worst case, a cross-grain joint. But just where do these little suckers come from? Kathleen Oberleiter, the dealer sales manager for Lamello, says her company has one plant in Switzerland that produces biscuits for Europe and the United States. In addition to producing biscuits under its own name, she says Lamello also makes the same quality biscuits for Makita and Black & Decker (and Black & Decker's sister company, DeWalt). Lamello (800-252-6355) employs two people whose job is to find the perfect European beech trees for making biscuits.They look for trees that are at a particular stage of growth and choose those for harvesting.The trees are debarked, cut into thin panels and kiln-dried.When the panels are dry the biscuits are stamped and compressed from those panels. Lamello brags that all its biscuits are within one-tenth of a millimeter in thickness and with a moisture content between 8 and 10 percent. Here in the United States, Porter-Cable (800-487-8665) started making its own biscuits in Jackson,Tenn., in the mid-1980s,according to company officials.Then the company concluded it would be better to have another company make the biscuits using Porter-Cable's tooling and equipment. Now Hill Wood Products of Cook, Minnesota,makes all of Porter-Cable's biscuits.The company also makes Ryobi's face frame biscuits. In fact, Hill Wood's plant is the only major producer of biscuits in this country and makes between 60 percent and 70 percent of the biscuits sold in the United States, says Hill Wood President Steve Hill. Since his company started making biscuits for Porter-Cable, Hill says his company has upgraded the original equipment three or four times and can now easily make 1 million biscuits a day. Hermann Steiner, inventor of the Lamello joining system. Instead of beech, Hill Wood makes biscuits using Northern white birch from Minnesota, most of which comes from within a 150-mile radius of the plant. The trees are sawn using special equipment and then dried to a moisture content between 6 percent and 8 percent.Then the strips of birch are transformed into biscuits by the company's machinery. Interestingly, Hill says Hill Wood does not compress the wood for its biscuits and relies on the moisture in the glue to swell the biscuit and lock the joint tight.The company's equipment is capable of compressing the biscuits,but Hill says he's found that wood can compress unevenly, resulting in biscuits of different thicknesses. Hill Wood cuts its biscuits within 5-thousandths of the optimum thickness. So how does birch compare to the European beech? Hill says beech is actually a little harder and the grain is a bit tighter than in birch, but that it's real close."The glue or the wood is more likely to fail than the biscuit," he says. Freud (800-334-4l07),a major player in the biscuit market, has its biscuits made by a Spanish firm that makes biscuits for many other firms, according to Jim Brewer,vice president of operations. Freud's biscuits are made of beech and are compressed, he says. Biscuits sold by Ryobi (800-323-4615) are manufactured in Minnesota from beech and are compressed, company officials say. Kaiser biscuits, which are made in Austria from beech, have been distributed in the United States for the last five or six years by Practical Products Co. (800-847-8839) of Cincinnati,Ohio, according to Donald Baltzer, company president. Kaisers are well thought of in Europe and are compressed during manufacturing. 28 Popular Woodworking June 2001 |