Popular Woodworking 2001-08 № 123, страница 16

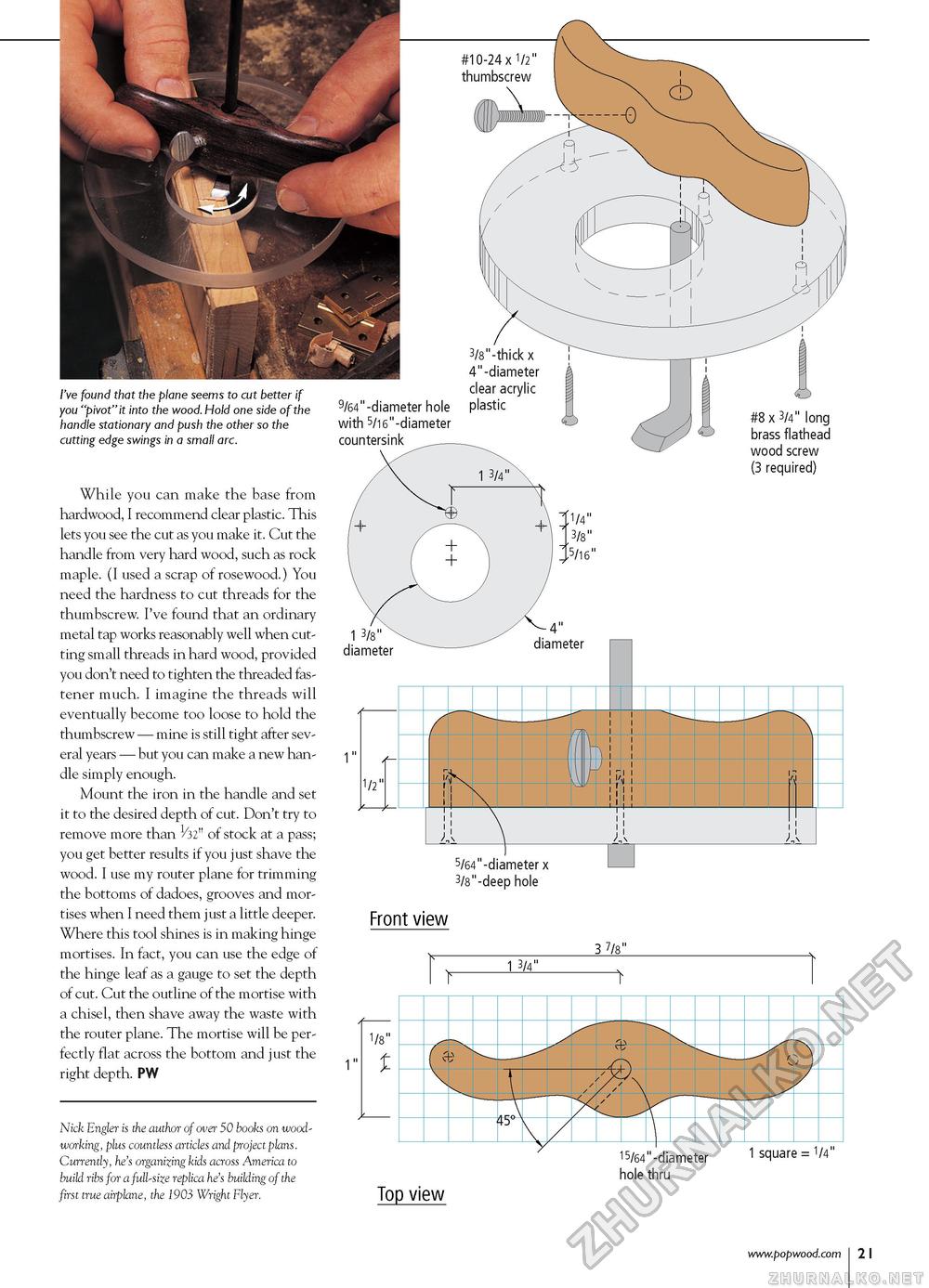

I've found that the plane seems to cut better if you "pivot" it into the wood. Hold one side of the handle stationary and push the other so the cutting edge swings in a small arc. While you can make the base from hardwood, I recommend clear plastic. This lets you see the cut as you make it. Cut the handle from very hard wood, such as rock maple. (I used a scrap of rosewood.) You need the hardness to cut threads for the thumbscrew. I've found that an ordinary metal tap works reasonably well when cutting small threads in hard wood, provided you don't need to tighten the threaded fastener much. I imagine the threads will eventually become too loose to hold the thumbscrew — mine is still tight after several years — but you can make a new handle simply enough. Mount the iron in the handle and set it to the desired depth of cut. Don't try to remove more than V32" of stock at a pass; you get better results if you just shave the wood. I use my router plane for trimming the bottoms of dadoes, grooves and mortises when I need them just a little deeper. Where this tool shines is in making hinge mortises. In fact, you can use the edge of the hinge leaf as a gauge to set the depth of cut. Cut the outline of the mortise with a chisel, then shave away the waste with the router plane. The mortise will be perfectly flat across the bottom and just the right depth. PW Nick Engler is the author of over 50 books on woodworking, plus countless articles and project plans. Currently, he's organizing kids across America to build ribs for a full-size replica he's building of the first true airplane, the 1903 Wright Flyer. 9/64"-diameter hole with 5/16"-diameter countersink #8 x 3/4" long brass flathead wood screw (3 required) 5/64"-diameter x 3/8"-deep hole Front view 3 7/8" 1 3/4" 15/64"-diameter hole thru 1 square = 1/4" Top view |