Popular Woodworking 2001-08 № 123, страница 28

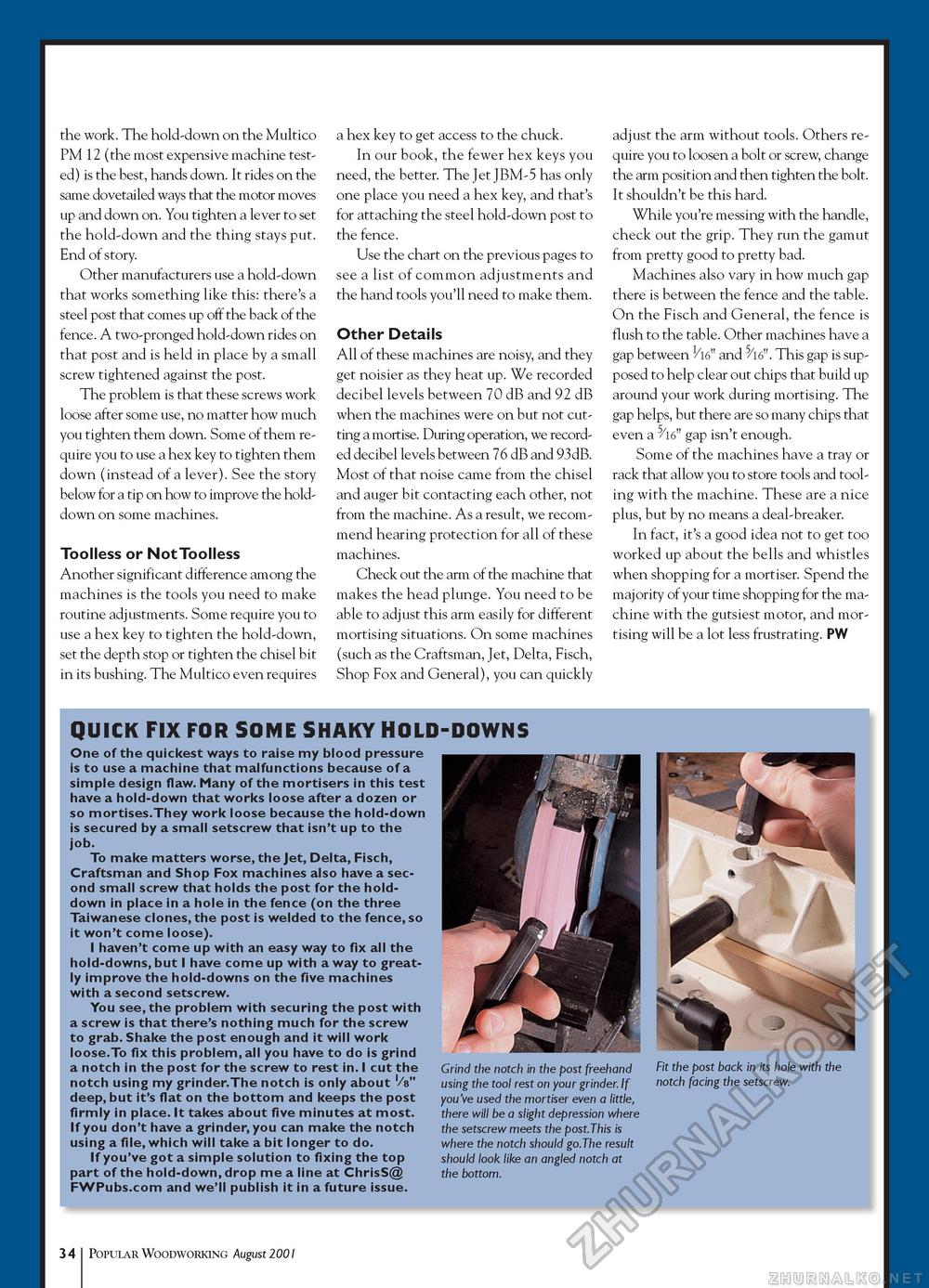

the work. The hold-down on the Multico PM 12 (the most expensive machine tested) is the best, hands down. It rides on the same dovetailed ways that the motor moves up and down on. You tighten a lever to set the hold-down and the thing stays put. End of story. Other manufacturers use a hold-down that works something like this: there's a steel post that comes up off the back of the fence. A two-pronged hold-down rides on that post and is held in place by a small screw tightened against the post. The problem is that these screws work loose after some use, no matter how much you tighten them down. Some of them require you to use a hex key to tighten them down (instead of a lever). See the story below for a tip on how to improve the hold-down on some machines. Toolless or Not Toolless Another significant difference among the machines is the tools you need to make routine adjustments. Some require you to use a hex key to tighten the hold-down, set the depth stop or tighten the chisel bit in its bushing. The Multico even requires a hex key to get access to the chuck. In our book, the fewer hex keys you need, the better. The Jet JBM-5 has only one place you need a hex key, and that's for attaching the steel hold-down post to the fence. Use the chart on the previous pages to see a list of common adjustments and the hand tools you'll need to make them. Other Details All of these machines are noisy, and they get noisier as they heat up. We recorded decibel levels between 70 dB and 92 dB when the machines were on but not cutting a mortise. During operation, we recorded decibel levels between 76 dB and 93dB. Most of that noise came from the chisel and auger bit contacting each other, not from the machine. As a result, we recommend hearing protection for all of these machines. Check out the arm of the machine that makes the head plunge. You need to be able to adjust this arm easily for different mortising situations. On some machines (such as the Craftsman, Jet, Delta, Fisch, Shop Fox and General), you can quickly adjust the arm without tools. Others require you to loosen a bolt or screw, change the arm position and then tighten the bolt. It shouldn't be this hard. While you're messing with the handle, check out the grip. They run the gamut from pretty good to pretty bad. Machines also vary in how much gap there is between the fence and the table. On the Fisch and General, the fence is flush to the table. Other machines have a gap between 1/16" and 5/16". This gap is supposed to help clear out chips that build up around your work during mortising. The gap helps, but there are so many chips that even a gap isn't enough. Some of the machines have a tray or rack that allow you to store tools and tooling with the machine. These are a nice plus, but by no means a deal-breaker. In fact, it's a good idea not to get too worked up about the bells and whistles when shopping for a mortiser. Spend the majority of your time shopping for the machine with the gutsiest motor, and mortising will be a lot less frustrating. PW QUICK Fix FOR SOME SHAKY HOLD-DOWNS One of the quickest ways to raise my blood pressure is to use a machine that malfunctions because of a simple design flaw. Many of the mortisers in this test have a hold-down that works loose after a dozen or so mortises.They work loose because the hold-down is secured by a small setscrew that isn't up to the job. To make matters worse, the Jet, Delta, Fisch, Craftsman and Shop Fox machines also have a second small screw that holds the post for the hold-down in place in a hole in the fence (on the three Taiwanese clones, the post is welded to the fence, so it won't come loose). I haven't come up with an easy way to fix all the hold-downs, but I have come up with a way to greatly improve the hold-downs on the five machines with a second setscrew. You see, the problem with securing the post with a screw is that there's nothing much for the screw to grab. Shake the post enough and it will work loose.To fix this problem, all you have to do is grind a notch in the post for the screw to rest in. I cut the notch using my grinder.The notch is only about tV deep, but it's flat on the bottom and keeps the post firmly in place. It takes about five minutes at most. If you don't have a grinder, you can make the notch using a file, which will take a bit longer to do. If you've got a simple solution to fixing the top part of the hold-down, drop me a line at ChrisS@ FWPubs.com and we'll publish it in a future issue. Grind the notch in the post freehand using the tool rest on your grinder. If you've used the mortiser even a little, there will be a slight depression where the setscrew meets the post.This is where the notch should go.The result should look like an angled notch at the bottom. Fit the post back in its hole with the notch facing the setscrew. 34 Popular Woodworking August 2001 |