Popular Woodworking 2001-08 № 123, страница 6

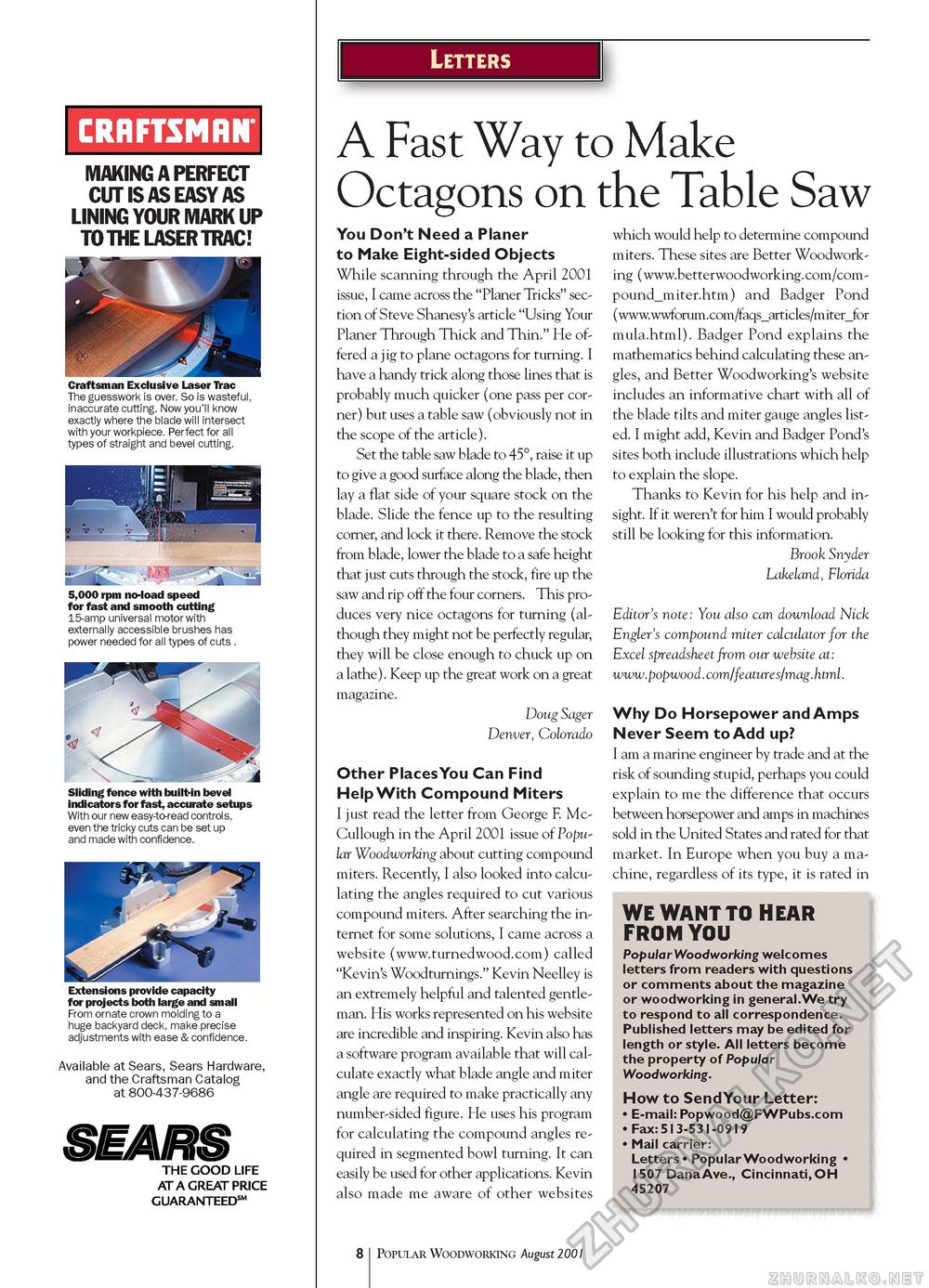

Letters MAKING A PERFECT CUT IS AS EASY AS LINING YOUR MARK UP TO THE LASER TRAC! Craftsman Exclusive Laser ITac The guesswork is over. So is wasteful, inaccurate cutting. Now you'll know exactly where the blade will intersect with your workpiece. Perfect for all types of straight and bevel cutting. 5,000 rpm no-load speed for fast and smooth cutting 15-amp universal motor with externally accessible brushes has power needed for all types of cuts . Sliding fence with built-in bevel indicators for fast, accurate setups With our new easy-to-read controls, even the tricky cuts can be set up and made with confidence. Extensions provide capacity for projects both large and small From ornate crown molding to a huge backyard deck, make precise adjustments with ease & confidence. Available at Sears, Sears Hardware, and the Craftsman Catalog at 800-437-9686 THE GOOD LIFE ATA GREAT PRICE GUARANTEED™ A Fast Way to Make Octagons on the Table Saw You Don't Need a Planer to Make Eight-sided Objects While scanning through the April 2001 issue, I came across the "Planer Tricks" section of Steve Shanesy's article "Using Your Planer Through Thick and Thin." He offered a jig to plane octagons for turning. I have a handy trick along those lines that is probably much quicker (one pass per corner) but uses a table saw (obviously not in the scope of the article). Set the table saw blade to 45°, raise it up to give a good surface along the blade, then lay a flat side of your square stock on the blade. Slide the fence up to the resulting corner, and lock it there. Remove the stock from blade, lower the blade to a safe height that just cuts through the stock, fire up the saw and rip off the four corners. This produces very nice octagons for turning (although they might not be perfectly regular, they will be close enough to chuck up on a lathe). Keep up the great work on a great magazine. Doug Sager Denver, Colorado Other Places You Can Find Help With Compound Miters I just read the letter from George F. Mc-Cullough in the April 2001 issue of Popular Woodworking about cutting compound miters. Recently, I also looked into calculating the angles required to cut various compound miters. After searching the internet for some solutions, I came across a website (www.turnedwood.com) called "Kevin's Woodturnings." Kevin Neelley is an extremely helpful and talented gentleman. His works represented on his website are incredible and inspiring. Kevin also has a software program available that will calculate exactly what blade angle and miter angle are required to make practically any number-sided figure. He uses his program for calculating the compound angles required in segmented bowl turning. It can easily be used for other applications. Kevin also made me aware of other websites which would help to determine compound miters. These sites are Better Woodworking (www.betterwoodworking.com/com-pound_miter.htm) and Badger Pond (www.wwforum.com/faqs_articles/miter_for mula.html). Badger Pond explains the mathematics behind calculating these angles, and Better Woodworking's website includes an informative chart with all of the blade tilts and miter gauge angles listed. I might add, Kevin and Badger Pond's sites both include illustrations which help to explain the slope. Thanks to Kevin for his help and insight. If it weren't for him I would probably still be looking for this information. Brook Snyder Lakeland, Florida Editor's note: You also can download Nick Engler's compound miter calculator for the Excel spreadsheet from our website at: www.popwood.com/features/mag.html. Why Do Horsepower and Amps Never Seem to Add up? I am a marine engineer by trade and at the risk of sounding stupid, perhaps you could explain to me the difference that occurs between horsepower and amps in machines sold in the United States and rated for that market. In Europe when you buy a machine, regardless of its type, it is rated in WE WANT TO HEAR FROM YOU Popular Woodworking welcomes letters from readers with questions or comments about the magazine or woodworking in general.We try to respond to all correspondence. Published letters may be edited for length or style. All letters become the property of Popular Woodworking. How to SendYour Letter: • E-mail: Popwood@FWPubs.com • Fax:513-531-0919 • Mail carrier: Letters • Popular Woodworking • 1507 Dana Ave., Cincinnati, OH 45207 8 Popular Woodworking August 2001 |