Popular Woodworking 2001-10 № 124, страница 6

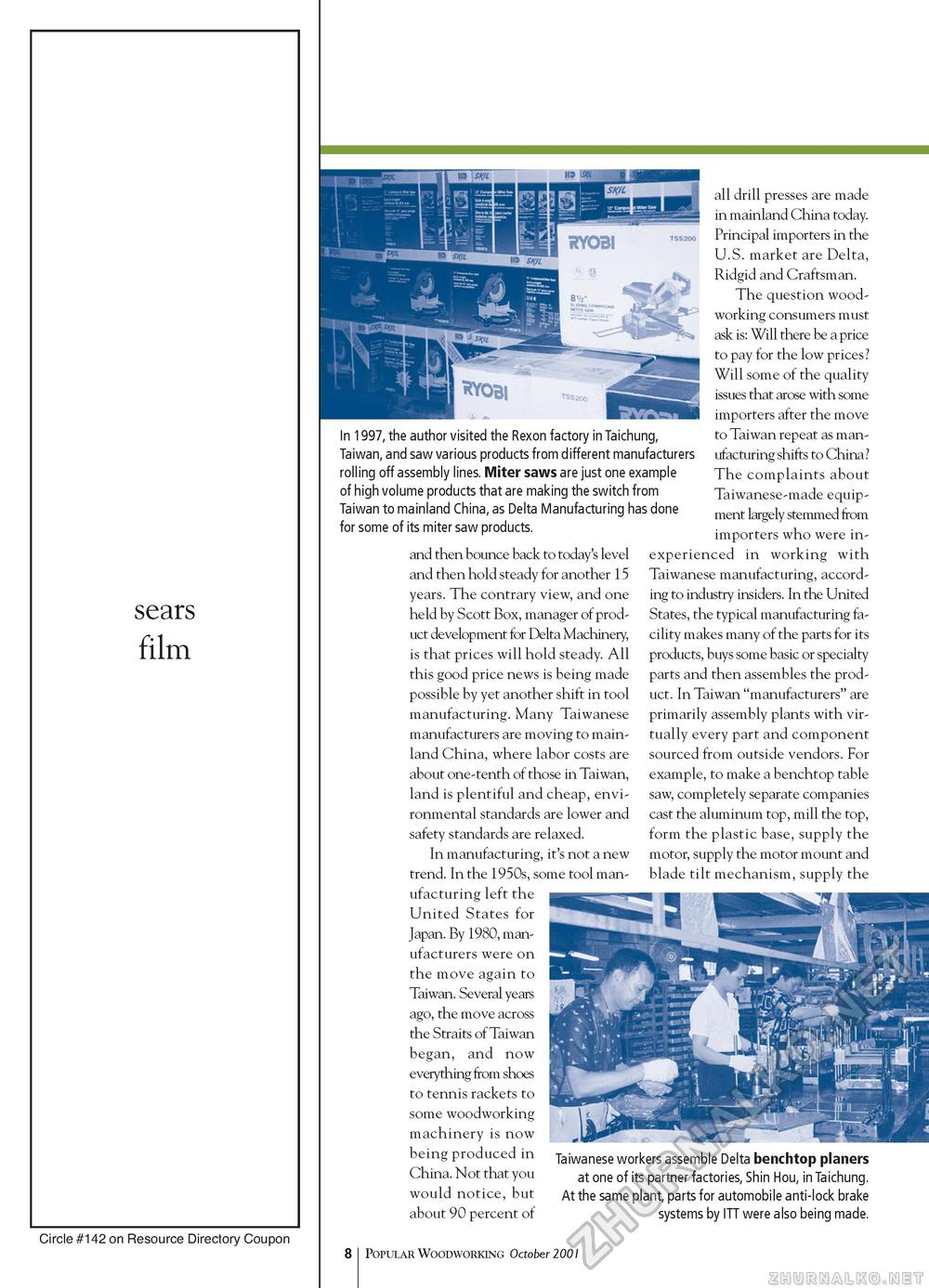

sears film In 1997, the author visited the Rexon factory in Taichung, Taiwan, and saw various products from different manufacturers rolling off assembly lines. Miter saws are just one example of high volume products that are making the switch from Taiwan to mainland China, as Delta Manufacturing has done for some of its miter saw products. and then bounce back to today's level and then hold steady for another 15 years. The contrary view, and one held by Scott Box, manager of product development for Delta Machinery, is that prices will hold steady. All this good price news is being made possible by yet another shift in tool manufacturing. Many Taiwanese manufacturers are moving to mainland China, where labor costs are about one-tenth of those in Taiwan, land is plentiful and cheap, environmental standards are lower and safety standards are relaxed. In manufacturing, it's not a new trend. In the 1950s, some tool manufacturing left the United States for Japan. By 1980, manufacturers were on the move again to Taiwan. Several years ago, the move across the Straits of Taiwan began, and now everything from shoes to tennis rackets to some woodworking machinery is now being produced in China. Not that you would notice, but about 90 percent of all drill presses are made in mainland China today. Principal importers in the U.S. market are Delta, Ridgid and Craftsman. The question woodworking consumers must ask is: Will there be a price to pay for the low prices? Will some of the quality issues that arose with some importers after the move to Taiwan repeat as manufacturing shifts to China? The complaints about Taiwanese-made equipment largely stemmed from importers who were inexperienced in working with Taiwanese manufacturing, according to industry insiders. In the United States, the typical manufacturing facility makes many of the parts for its products, buys some basic or specialty parts and then assembles the product. In Taiwan "manufacturers" are primarily assembly plants with virtually every part and component sourced from outside vendors. For example, to make a benchtop table saw, completely separate companies cast the aluminum top, mill the top, form the plastic base, supply the motor, supply the motor mount and blade tilt mechanism, supply the Taiwanese workers assemble Delta benchtop planers at one of its partner factories, Shin Hou, in Taichung. At the same plant, parts for automobile anti-lock brake systems by ITT were also being made. Circle #142 on Resource Directory Coupon 10 Popular Woodworking October 2001 |