Popular Woodworking 2001-10 № 124, страница 7

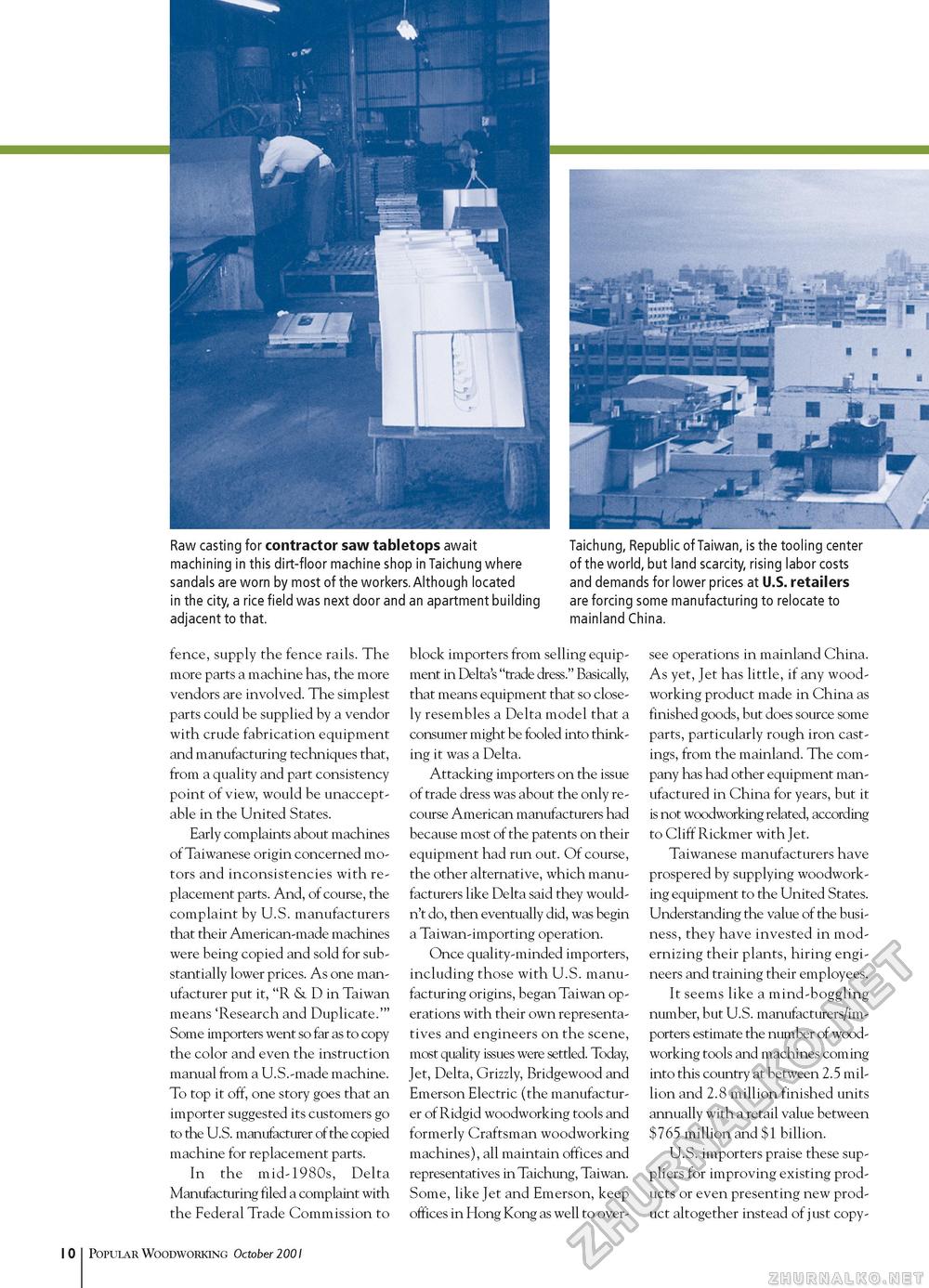

■'■■■J Raw casting for contractor saw tabletops await machining in this dirt-floor machine shop in Taichung where sandals are worn by most of the workers. Although located in the city, a rice field was next door and an apartment building adjacent to that. Taichung, Republic of Taiwan, is the tooling center of the world, but land scarcity, rising labor costs and demands for lower prices at U.S. retailers are forcing some manufacturing to relocate to mainland China. fence, supply the fence rails. The more parts a machine has, the more vendors are involved. The simplest parts could be supplied by a vendor with crude fabrication equipment and manufacturing techniques that, from a quality and part consistency point of view, would be unacceptable in the United States. Early complaints about machines of Taiwanese origin concerned motors and inconsistencies with replacement parts. And, of course, the complaint by U.S. manufacturers that their American-made machines were being copied and sold for substantially lower prices. As one manufacturer put it, "R & D in Taiwan means 'Research and Duplicate.'" Some importers went so far as to copy the color and even the instruction manual from a U.S.-made machine. To top it off, one story goes that an importer suggested its customers go to the U.S. manufacturer of the copied machine for replacement parts. In the mid-1980s, Delta Manufacturing filed a complaint with the Federal Trade Commission to block importers from selling equipment in Delta's "trade dress." Basically, that means equipment that so closely resembles a Delta model that a consumer might be fooled into thinking it was a Delta. Attacking importers on the issue of trade dress was about the only recourse American manufacturers had because most of the patents on their equipment had run out. Of course, the other alternative, which manufacturers like Delta said they wouldn't do, then eventually did, was begin a Taiwan-importing operation. Once quality-minded importers, including those with U.S. manufacturing origins, began Taiwan operations with their own representatives and engineers on the scene, most quality issues were settled. Today, Jet, Delta, Grizzly, Bridgewood and Emerson Electric (the manufacturer of Ridgid woodworking tools and formerly Craftsman woodworking machines), all maintain offices and representatives in Taichung, Taiwan. Some, like Jet and Emerson, keep offices in Hong Kong as well to over see operations in mainland China. As yet, Jet has little, if any woodworking product made in China as finished goods, but does source some parts, particularly rough iron castings, from the mainland. The company has had other equipment manufactured in China for years, but it is not woodworking related, according to Cliff Rickmer with Jet. Taiwanese manufacturers have prospered by supplying woodworking equipment to the United States. Understanding the value of the business, they have invested in modernizing their plants, hiring engineers and training their employees. It seems like a mind-boggling number, but U.S. manufacturers/importers estimate the number of woodworking tools and machines coming into this country at between 2.5 million and 2.8 million finished units annually with a retail value between $765 million and $1 billion. U.S. importers praise these suppliers for improving existing products or even presenting new product altogether instead of just copy 10 Popular Woodworking October 2001 |