Popular Woodworking 2001-12 № 125, страница 15

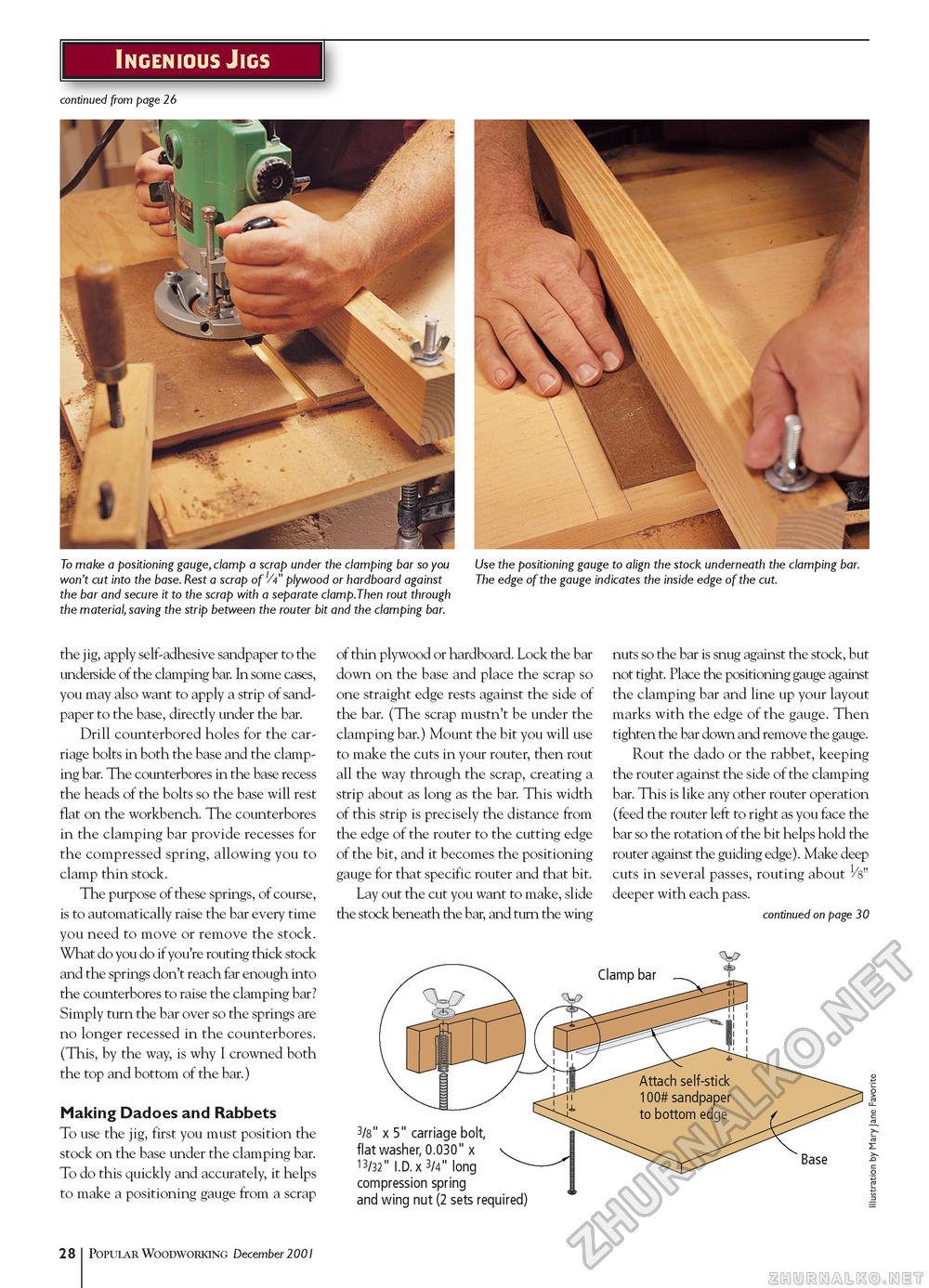

Ingenious Jigs continued from page lb To make a positioning gauge, clamp a scrap under the clamping bar so you Use the positioning gauge to align the stock underneath the clamping bar. won't cut into the base. Rest a scrap of 'A" plywood or hardboard against The edge of the gauge indicates the inside edge of the cut. the bar and secure it to the scrap with a separate clamp.Then rout through the material, saving the strip between the router bit and the clamping bar. the jig, apply self-adhesive sandpaper to the underside of the clamping bar. In some cases, you may also want to apply a strip of sandpaper to the base, directly under the bar. Drill counterbored holes for the carriage bolts in both the base and the clamping bar. The counterbores in the base recess the heads of the bolts so the base will rest flat on the workbench. The counterbores in the clamping bar provide recesses for the compressed spring, allowing you to clamp thin stock. The purpose of these springs, of course, is to automatically raise the bar every time you need to move or remove the stock. What do you do if you're routing thick stock and the springs don't reach far enough into the counterbores to raise the clamping bar? Simply turn the bar over so the springs are no longer recessed in the counterbores. (This, by the way, is why I crowned both the top and bottom of the bar.) Making Dadoes and Rabbets To use the jig, first you must position the stock on the base under the clamping bar. To do this quickly and accurately, it helps to make a positioning gauge from a scrap of thin plywood or hardboard. Lock the bar down on the base and place the scrap so one straight edge rests against the side of the bar. (The scrap mustn't be under the clamping bar.) Mount the bit you will use to make the cuts in your router, then rout all the way through the scrap, creating a strip about as long as the bar. This width of this strip is precisely the distance from the edge of the router to the cutting edge of the bit, and it becomes the positioning gauge for that specific router and that bit. Lay out the cut you want to make, slide the stock beneath the bar, and turn the wing nuts so the bar is snug against the stock, but not tight. Place the positioning gauge against the clamping bar and line up your layout marks with the edge of the gauge. Then tighten the bar down and remove the gauge. Rout the dado or the rabbet, keeping the router against the side of the clamping bar. This is like any other router operation (feed the router left to right as you face the bar so the rotation of the bit helps hold the router against the guiding edge). Make deep cuts in several passes, routing about Vs" deeper with each pass. continued on page 30 3/8" x 5" carriage bolt, flat washer, 0.030" x 13/32" I.D. x 3/4" long compression spring and wing nut (2 sets required) 28 PopularWoodworking December 1001 |