Popular Woodworking 2001-12 № 125, страница 57

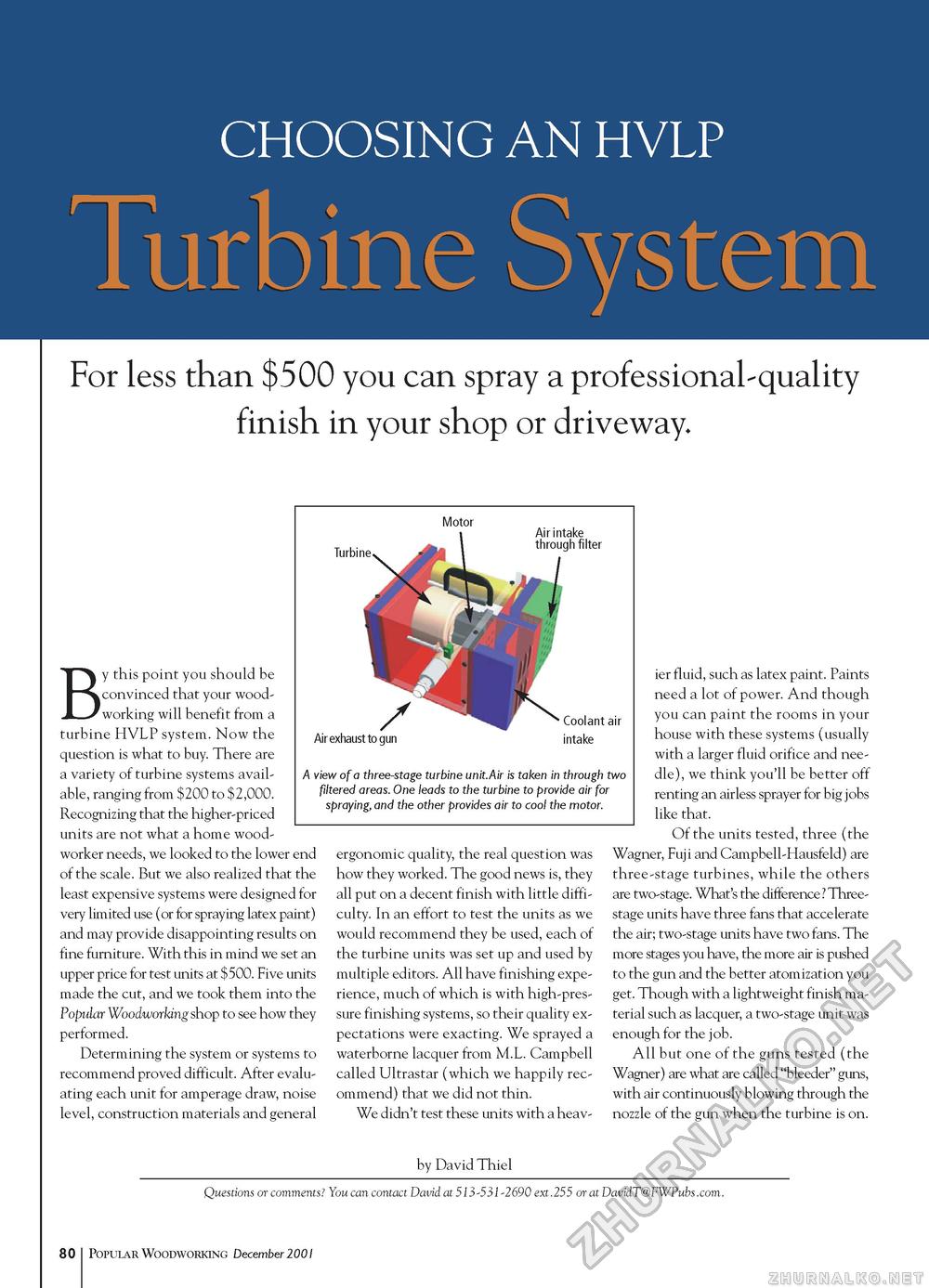

CHOOSING AN HVLPTurbine System For less than $500 you can spray a professional-quality finish in your shop or driveway. Motor Turbine By this point you should be convinced that your woodworking will benefit from a turbine HVLP system. Now the question is what to buy. There are a variety of turbine systems available, ranging from $200 to $2,000. Recognizing that the higher-priced units are not what a home woodworker needs, we looked to the lower end of the scale. But we also realized that the least expensive systems were designed for very limited use (or for spraying latex paint) and may provide disappointing results on fine furniture. With this in mind we set an upper price for test units at $500. Five units made the cut, and we took them into the Popular Woodworking shop to see how they performed. Determining the system or systems to recommend proved difficult. After evaluating each unit for amperage draw, noise level, construction materials and general Air exhaust to gun Air intake through filter Coolant air intake A view of a three-stage turbine unit.Air is taken in through two filtered areas. One leads to the turbine to provide air for spraying, and the other provides air to cool the motor. ergonomic quality, the real question was how they worked. The good news is, they all put on a decent finish with little difficulty. In an effort to test the units as we would recommend they be used, each of the turbine units was set up and used by multiple editors. All have finishing experience, much of which is with high-pressure finishing systems, so their quality expectations were exacting. We sprayed a waterborne lacquer from M.L. Campbell called Ultrastar (which we happily recommend) that we did not thin. We didn't test these units with a heav- ier fluid, such as latex paint. Paints need a lot of power. And though you can paint the rooms in your house with these systems (usually with a larger fluid orifice and needle), we think you'll be better off renting an airless sprayer for big jobs like that. Of the units tested, three (the Wagner, Fuji and Campbell-Hausfeld) are three-stage turbines, while the others are two-stage. What's the difference? Three-stage units have three fans that accelerate the air; two-stage units have two fans. The more stages you have, the more air is pushed to the gun and the better atomization you get. Though with a lightweight finish material such as lacquer, a two-stage unit was enough for the job. All but one of the guns tested (the Wagner) are what are called "bleeder" guns, with air continuously blowing through the nozzle of the gun when the turbine is on. by David Thiel Questions or comments? You can contact David at 513-531-2690 ext.255 or at DavidT@FWPubs.com. 80 Popular Woodworking December 2001 |