Popular Woodworking 2002-02 № 126, страница 76

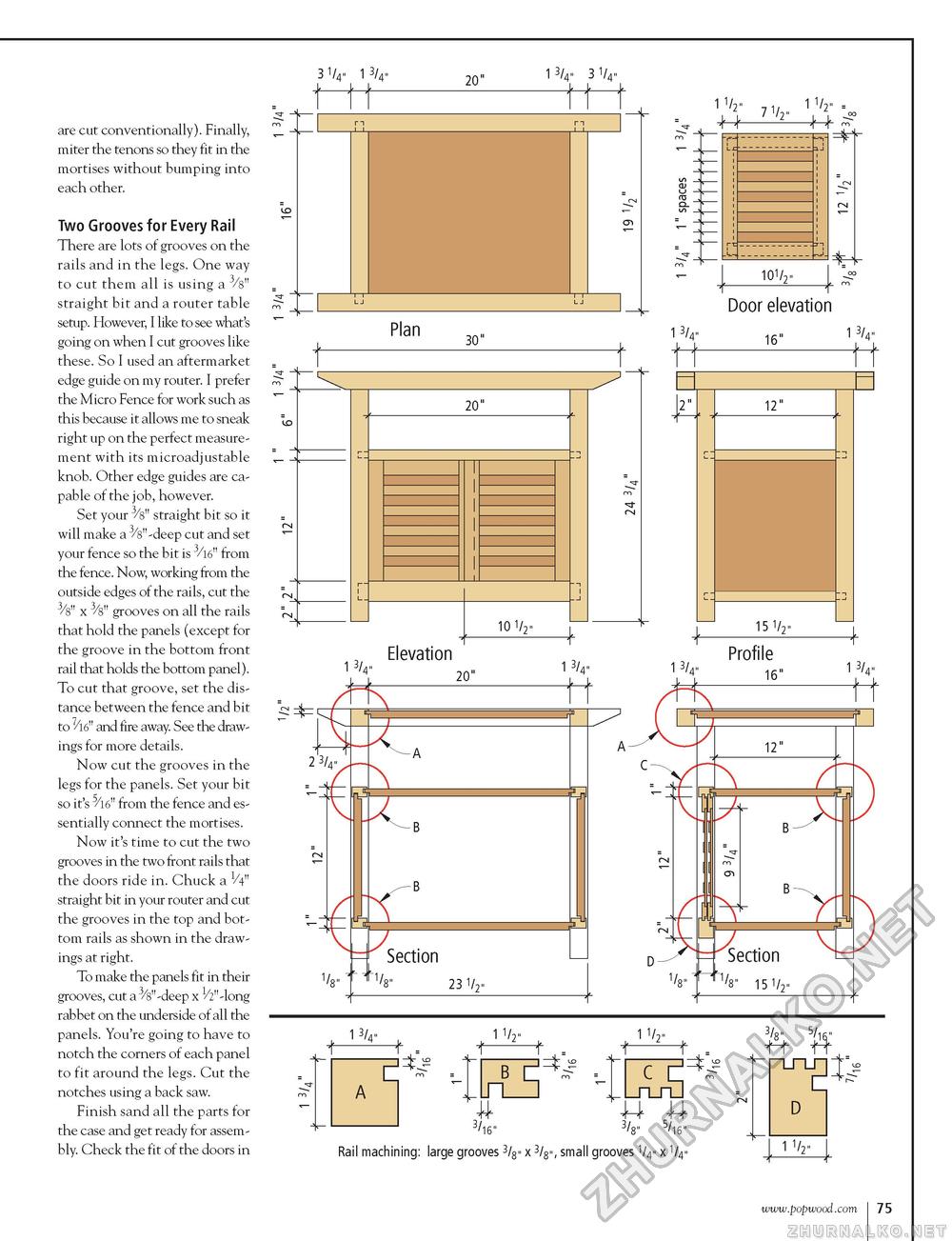

are cut conventionally). Finally, miter the tenons so they fit in the mortises without bumping into each other. Two Grooves for Every Rail There are lots of grooves on the rails and in the legs. One way to cut them all is using a 3/s" straight bit and a router table setup. However, I like to see what's going on when I cut grooves like these. So I used an aftermarket edge guide on my router. I prefer the Micro Fence for work such as this because it allows me to sneak right up on the perfect measurement with its microadjustable knob. Other edge guides are capable of the job, however. Set your 3/s" straight bit so it will make a 3/s"-deep cut and set your fence so the bit is 3/l6" from the fence. Now, working from the outside edges of the rails, cut the 3/8" x 3/8" grooves on all the rails that hold the panels (except for the groove in the bottom front rail that holds the bottom panel). To cut that groove, set the distance between the fence and bit to ^/16" and fire away. See the drawings for more details. Now cut the grooves in the legs for the panels. Set your bit so it's ^V from the fence and essentially connect the mortises. Now it's time to cut the two grooves in the two front rails that the doors ride in. Chuck a VV1 straight bit in your router and cut the grooves in the top and bottom rails as shown in the drawings at right. To make the panels fit in their grooves, cut a 3/8"-deep x 1/2"-long rabbet on the underside of all the panels. You're going to have to notch the corners of each panel to fit around the legs. Cut the notches using a back saw. Finish sand all the parts for the case and get ready for assembly. Check the fit of the doors in 3 1/4" 1 3/4 t-tt- 20" 1 3/4" 3 1/4" 1 1/2" 7 1/2" 1 1/2 101/2 Plan 30" 1 3/ 4 20" 1 3/4 -4 Elevation 10 v, Door elevation 16" 1 3/4 2" 12" 15 1/2 1 3/, 1 3/ 4 Profile s 1 3/4 1 3/4 A 1 1/2 1 1/2 B LTL 3/n \ \ 3/8" 5/16- b ru-ij]} Rail machining: large grooves 3/8" x 3/8", small grooves V4" x V4" D 1 1/2 www.popwood.com I 75 |