Popular Woodworking 2002-04 № 127, страница 28

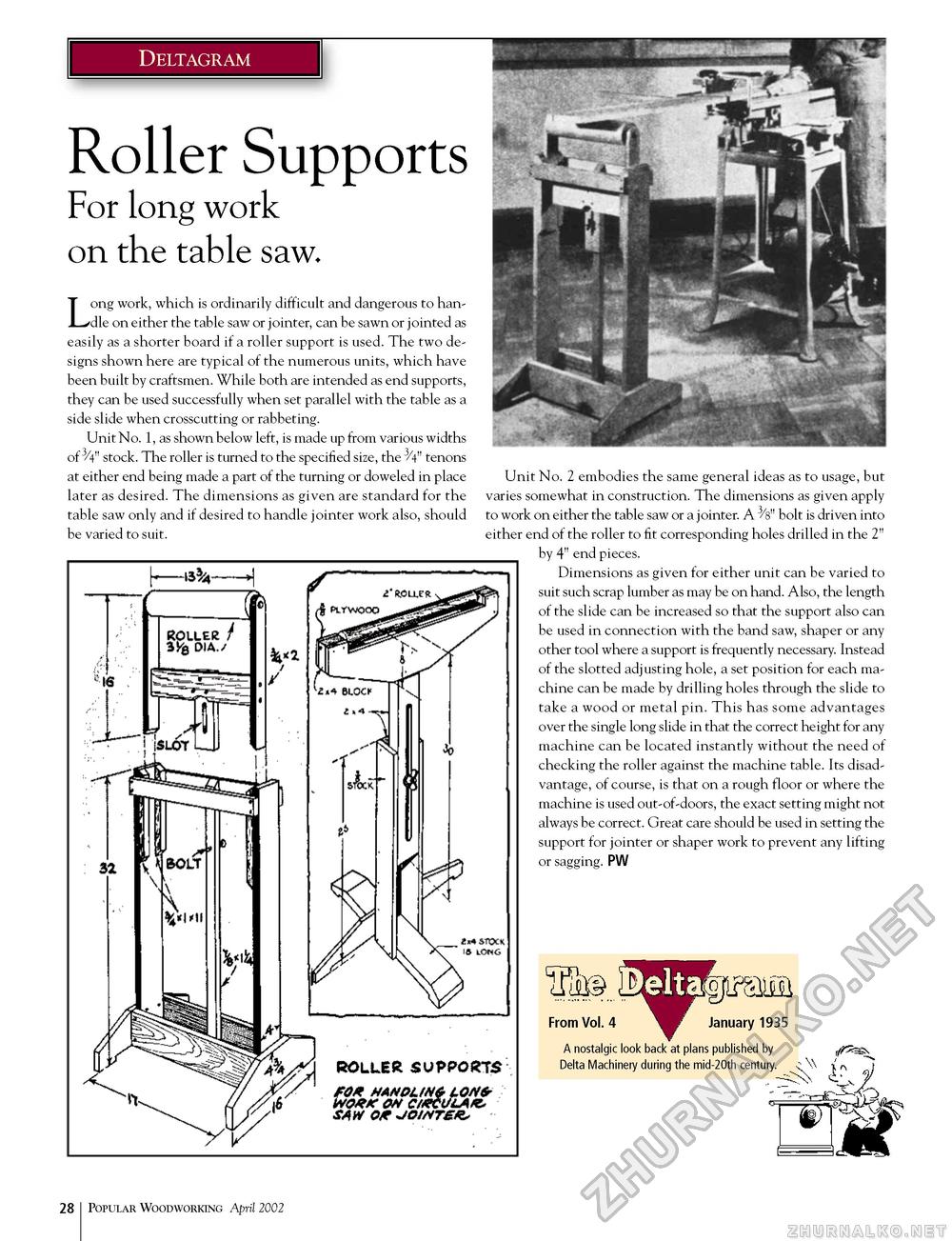

Deltagram Roller Supports For long work on the table saw. Long work, which is ordinarily difficult and dangerous to handle on either the table saw or jointer, can be sawn or jointed as easily as a shorter board if a roller support is used. The two designs shown here are typical of the numerous units, which have been built by craftsmen. While both are intended as end supports, they can be used successfully when set parallel with the table as a side slide when crosscutting or rabbeting. Unit No. 1, as shown below left, is made up from various widths of 3/4" stock. The roller is turned to the specified size, the 3/4" tenons at either end being made a part of the turning or doweled in place later as desired. The dimensions as given are standard for the table saw only and if desired to handle jointer work also, should be varied to suit. Unit No. 2 embodies the same general ideas as to usage, but varies somewhat in construction. The dimensions as given apply to work on either the table saw or a jointer. A 3/s" bolt is driven into either end of the roller to fit corresponding holes drilled in the 2" by 4" end pieces. Dimensions as given for either unit can be varied to suit such scrap lumber as may be on hand. Also, the length of the slide can be increased so that the support also can be used in connection with the band saw, shaper or any other tool where a support is frequently necessary. Instead of the slotted adjusting hole, a set position for each machine can be made by drilling holes through the slide to take a wood or metal pin. This has some advantages over the single long slide in that the correct height for any machine can be located instantly without the need of checking the roller against the machine table. Its disadvantage, of course, is that on a rough floor or where the machine is used out-of-doors, the exact setting might not always be correct. Great care should be used in setting the support for jointer or shaper work to prevent any lifting or sagging. PW 28 Popular Woodworking April 2002 |