Popular Woodworking 2002-06 № 128, страница 49

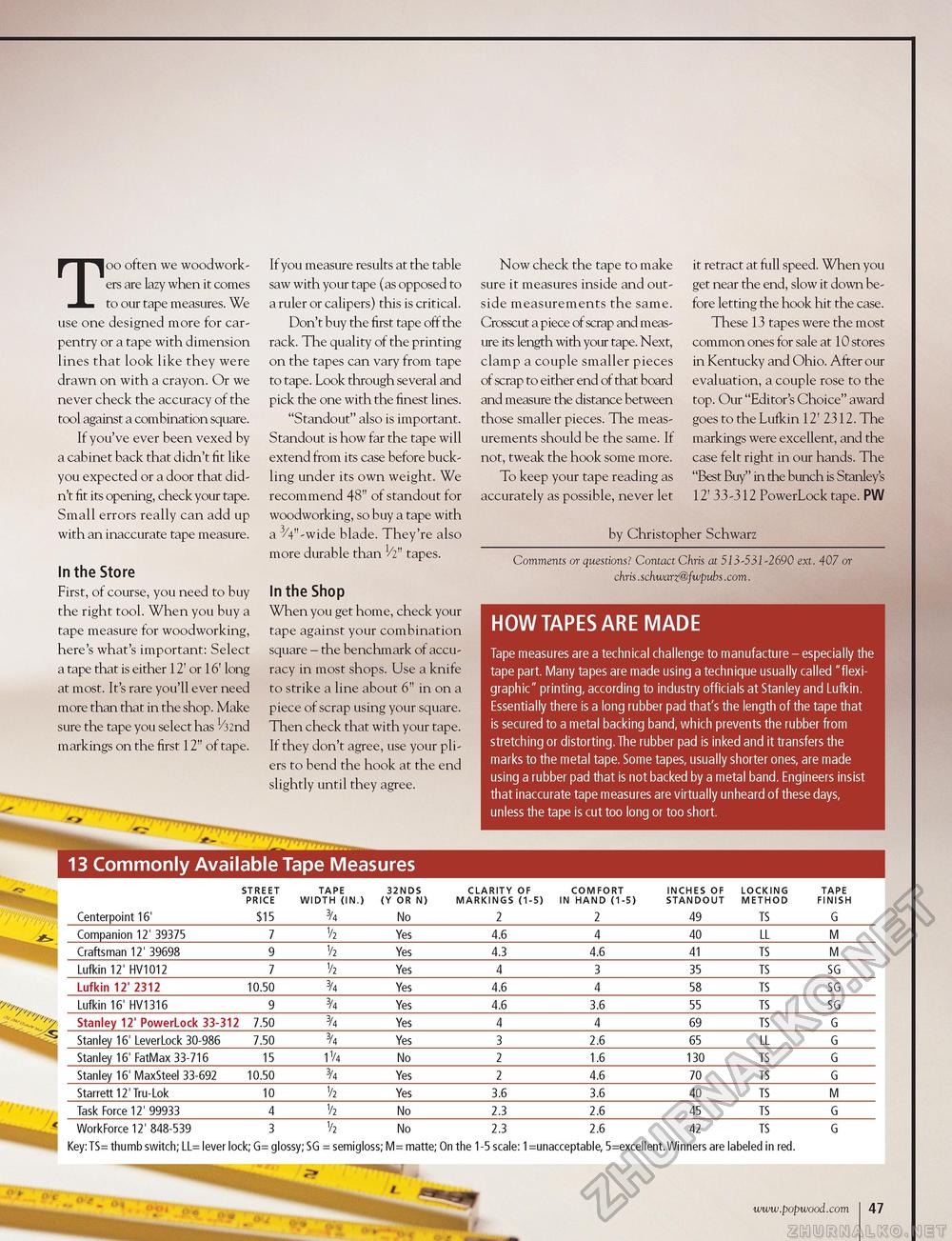

Too often we woodworkers are lazy when it comes to our tape measures. We use one designed more for carpentry or a tape with dimension lines that look like they were drawn on with a crayon. Or we never check the accuracy of the tool against a combination square. If you've ever been vexed by a cabinet back that didn't fit like you expected or a door that didn't fit its opening, check your tape. Small errors really can add up with an inaccurate tape measure. In the Store First, of course, you need to buy the right tool. When you buy a tape measure for woodworking, here's what's important: Select a tape that is either 12' or 16' long at most. It's rare you'll ever need more than that in the shop. Make sure the tape you select has 1/32nd markings on the first 12" of tape. If you measure results at the table saw with your tape (as opposed to a ruler or calipers) this is critical. Don't buy the first tape off the rack. The quality of the printing on the tapes can vary from tape to tape. Look through several and pick the one with the finest lines. "Standout" also is important. Standout is how far the tape will extend from its case before buckling under its own weight. We recommend 48" of standout for woodworking, so buy a tape with a 3/4"-wide blade. They're also more durable than 1/2" tapes. In the Shop When you get home, check your tape against your combination square - the benchmark of accuracy in most shops. Use a knife to strike a line about 6" in on a piece of scrap using your square. Then check that with your tape. If they don't agree, use your pliers to bend the hook at the end slightly until they agree. Now check the tape to make sure it measures inside and outside measurements the same. Crosscut a piece of scrap and measure its length with your tape. Next, clamp a couple smaller pieces of scrap to either end of that board and measure the distance between those smaller pieces. The measurements should be the same. If not, tweak the hook some more. To keep your tape reading as accurately as possible, never let it retract at full speed. When you get near the end, slow it down before letting the hook hit the case. These 13 tapes were the most common ones for sale at 10 stores in Kentucky and Ohio. After our evaluation, a couple rose to the top. Our "Editor's Choice" award goes to the Lufkin 12' 2312. The markings were excellent, and the case felt right in our hands. The "Best Buy" in the bunch is Stanley's 12' 33-312 PowerLock tape. PW by Christopher Schwarz Comments or questions? Contact Chris at 513-531-2690 ext. 407 or chris.schwarz@fwpubs.com. HOW TAPES ARE MADE Tape measures are a technical challenge to manufacture - especially the tape part. Many tapes are made using a technique usually called "flexi-graphic" printing, according to industry officials at Stanley and Lufkin. Essentially there is a long rubber pad that's the length of the tape that is secured to a metal backing band, which prevents the rubber from stretching or distorting.The rubber pad is inked and it transfers the marks to the metal tape. Some tapes, usually shorter ones, are made using a rubber pad that is not backed by a metal band. Engineers insist that inaccurate tape measures are virtually unheard of these days, unless the tape is cut too long or too short. 13 Commonly Available Tape Measures Hi

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||