Popular Woodworking 2002-06 № 128, страница 51

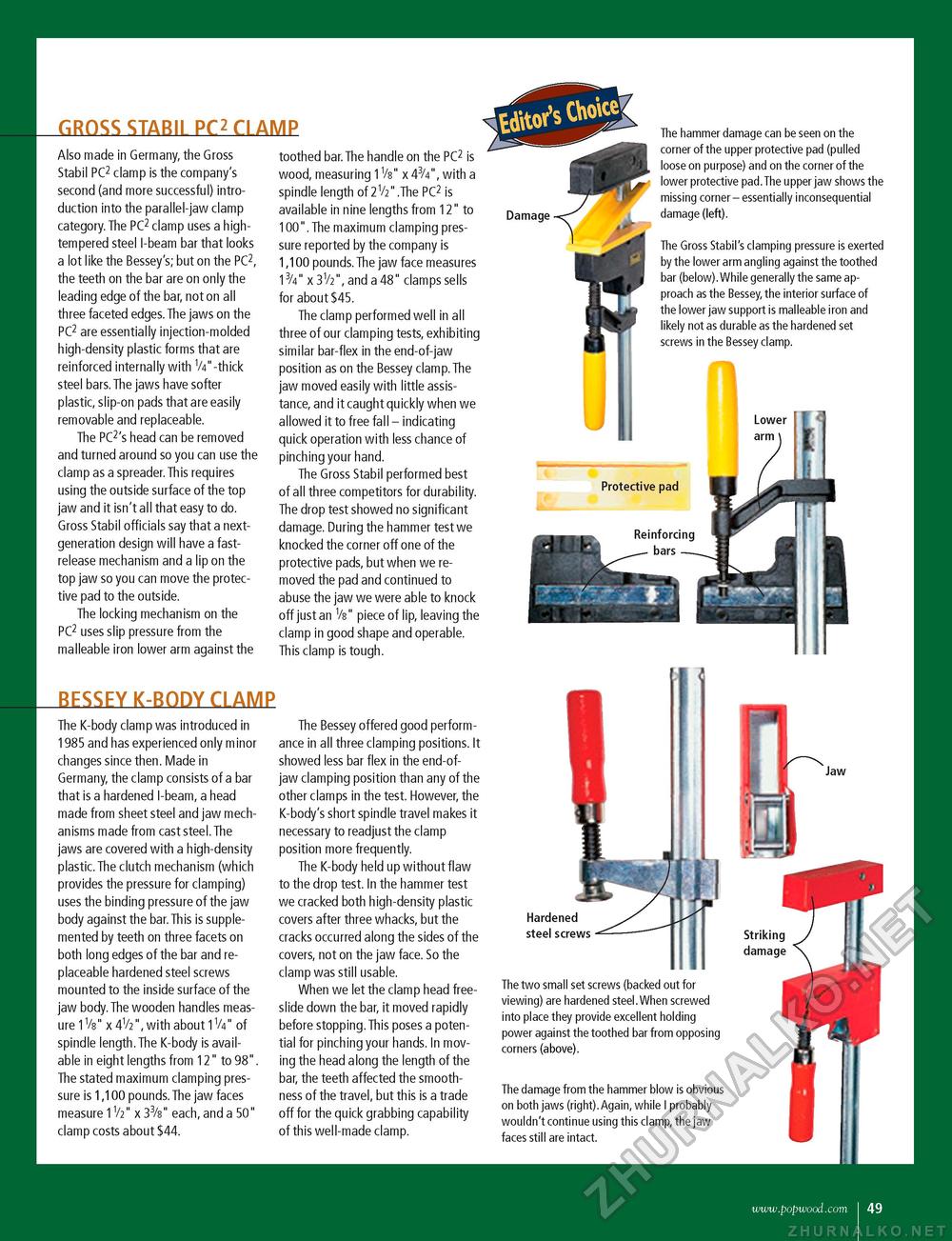

GROSS STABIL PC2 CLAMP Also made in Germany, the Gross Stabil PC2 clamp is the company's second (and more successful) introduction into the parallel-jaw clamp category. The PC2 clamp uses a high-tempered steel I-beam bar that looks a lot like the Bessey's; but on the PC2, the teeth on the bar are on only the leading edge of the bar, not on all three faceted edges. The jaws on the PC2 are essentially injection-molded high-density plastic forms that are reinforced internally with 1/4"-thick steel bars. The jaws have softer plastic, slip-on pads that are easily removable and replaceable. The PC2's head can be removed and turned around so you can use the clamp as a spreader. This requires using the outside surface of the top jaw and it isn't all that easy to do. Gross Stabil officials say that a next-generation design will have a fast-release mechanism and a lip on the top jaw so you can move the protective pad to the outside. The locking mechanism on the PC2 uses slip pressure from the malleable iron lower arm against the BESSEY K-BODY CLAMP The K-body clamp was introduced in 1985 and has experienced only minor changes since then. Made in Germany, the clamp consists of a bar that is a hardened I-beam, a head made from sheet steel and jaw mechanisms made from cast steel. The jaws are covered with a high-density plastic. The clutch mechanism (which provides the pressure for clamping) uses the binding pressure of the jaw body against the bar. This is supplemented by teeth on three facets on both long edges of the bar and replaceable hardened steel screws mounted to the inside surface of the jaw body. The wooden handles measure 1/8" x 4V2", with about 1V4" of spindle length.The K-body is available in eight lengths from 12" to 98". The stated maximum clamping pressure is 1,100 pounds. The jaw faces measure 1V2" x 33/8" each, and a 50" clamp costs about $44. toothed bar. The handle on the PC2 is wood, measuring 11/8" x 43/4", with a spindle length of 21/2".The PC2 is available in nine lengths from 12" to 100".The maximum clamping pressure reported by the company is 1,100 pounds. The jaw face measures 13/4" x 31/2",and a 48" clamps sells for about $45. The clamp performed well in all three of our clamping tests, exhibiting similar bar-flex in the end-of-jaw position as on the Bessey clamp.The jaw moved easily with little assistance, and it caught quickly when we allowed it to free fall - indicating quick operation with less chance of pinching your hand. The Gross Stabil performed best of all three competitors for durability. The drop test showed no significant damage. During the hammer test we knocked the corner off one of the protective pads, but when we removed the pad and continued to abuse the jaw we were able to knock off just an 1/8" piece of lip, leaving the clamp in good shape and operable. This clamp is tough. The Bessey offered good performance in all three clamping positions. It showed less bar flex in the end-of-jaw clamping position than any of the other clamps in the test. However, the K-body's short spindle travel makes it necessary to readjust the clamp position more frequently. The K-body held up without flaw to the drop test. In the hammer test we cracked both high-density plastic covers after three whacks, but the cracks occurred along the sides of the covers, not on the jaw face. So the clamp was still usable. When we let the clamp head free-slide down the bar, it moved rapidly before stopping. This poses a potential for pinching your hands. In moving the head along the length of the bar, the teeth affected the smoothness of the travel, but this is a trade off for the quick grabbing capability of this well-made clamp. The hammer damage can be seen on the corner of the upper protective pad (pulled loose on purpose) and on the corner of the lower protective pad.The upper jaw shows the missing corner - essentially inconsequential damage (left). The Gross Stabil's clamping pressure is exerted by the lower arm angling against the toothed bar (below).While generally the same approach as the Bessey, the interior surface of the lower jaw support is malleable iron and likely not as durable as the hardened set screws in the Bessey clamp. Lower arm 1 Protective pad Hardened steel screws The two small set screws (backed out for viewing) are hardened steel.When screwed into place they provide excellent holding power against the toothed bar from opposing corners (above). The damage from the hammer blow is obvious on both jaws (right). Again, while I probably wouldn't continue using this clamp, the jaw faces still are intact. www.popwood.com I 49 |