Popular Woodworking 2002-10 № 130, страница 83

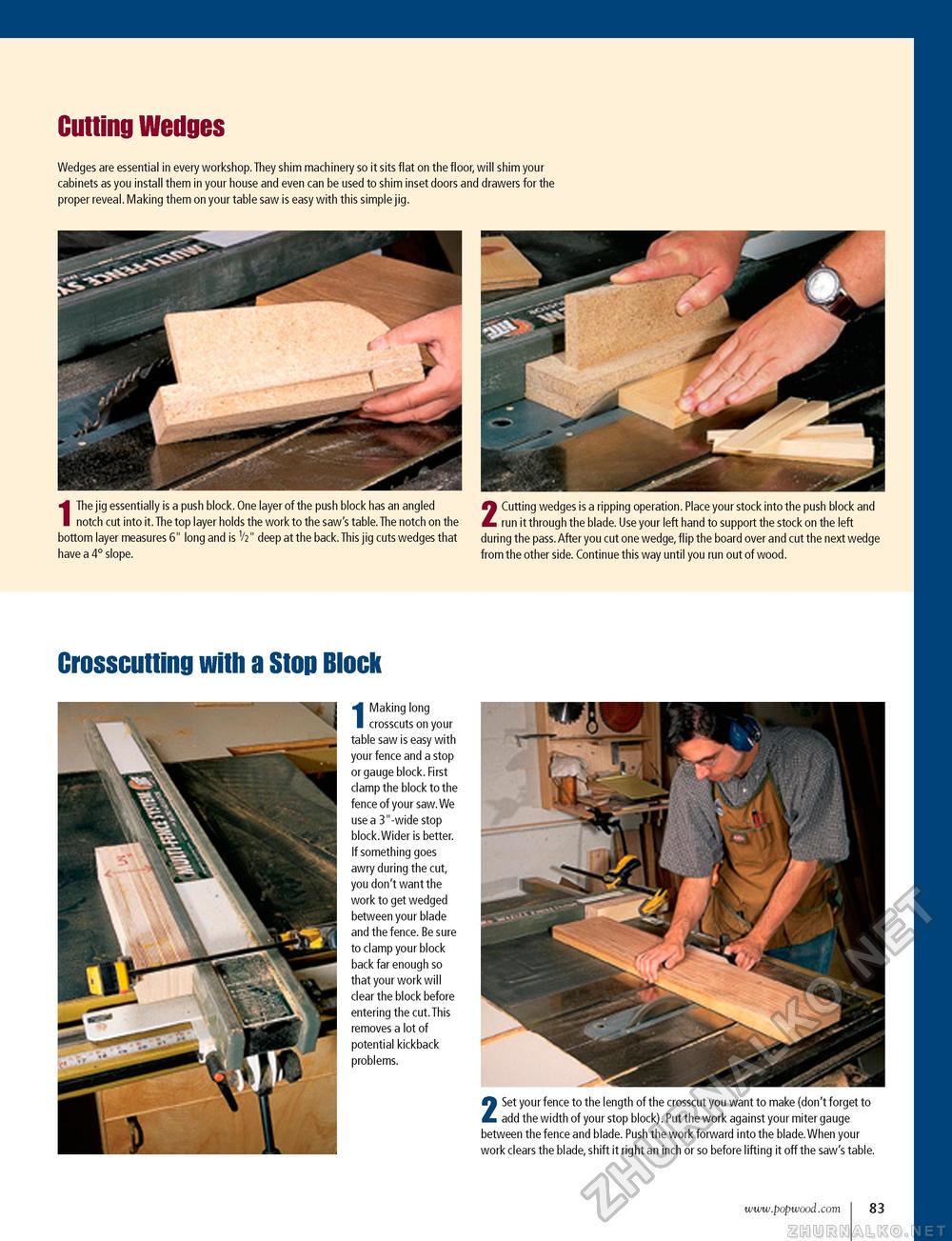

Cutting Wedges Wedges are essential in every workshop.They shim machinery so it sits flat on the floor, will shim your cabinets as you install them in your house and even can be used to shim inset doors and drawers for the proper reveal. Making them on your table saw is easy with this simple jig. IThe jig essentially is a push block. One layer of the push block has an angled notch cut into it. The top layer holds the work to the saw's table.The notch on the bottom layer measures 6" long and is V2" deep at the back. This jig cuts wedges that have a 4° slope. 2 Cutting wedges is a ripping operation. Place your stock into the push block and run it through the blade. Use your left hand to support the stock on the left during the pass.After you cut one wedge, flip the board over and cut the next wedge from the other side. Continue this way until you run out of wood. Crosscutting with a Stop Block 1 Making long crosscuts on your table saw is easy with your fence and a stop or gauge block. First clamp the block to the fence of your saw. We use a 3"-wide stop block.Wider is better. If something goes awry during the cut, you don't want the work to get wedged between your blade and the fence. Be sure to clamp your block back far enough so that your work will clear the block before entering the cut.This removes a lot of potential kickback problems. 2 Set your fence to the length of the crosscut you want to make (don't forget to add the width of your stop block). Put the work against your miter gauge between the fence and blade. Push the work forward into the blade.When your work clears the blade, shift it right an inch or so before lifting it off the saw's table. 83 |