Popular Woodworking 2002-10 № 130, страница 90

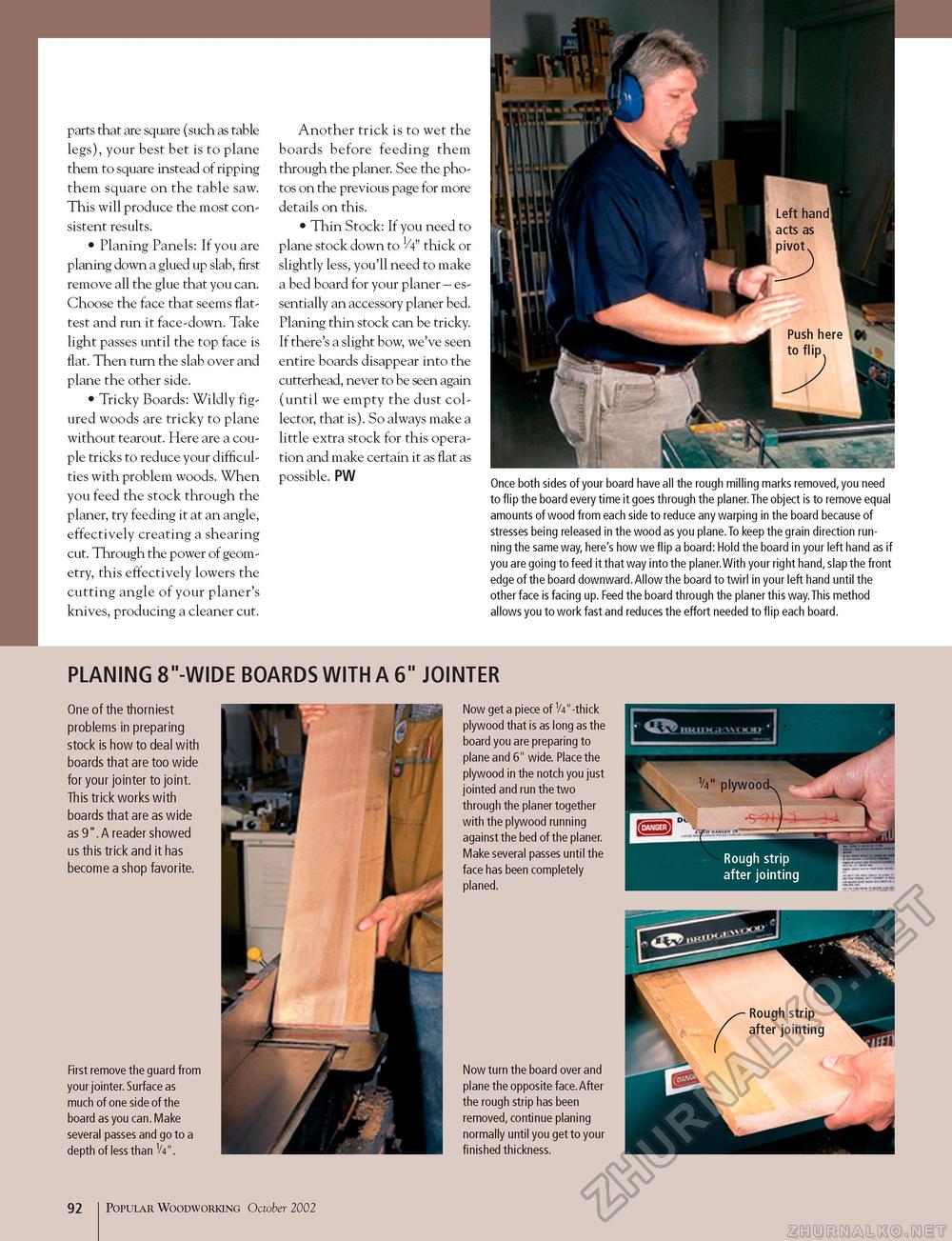

parts that are square (such as table legs), your best bet is to plane them to square instead of ripping them square on the table saw. This will produce the most consistent results. • Planing Panels: If you are planing down a glued up slab, first remove all the glue that you can. Choose the face that seems flattest and run it face-down. Take light passes until the top face is flat. Then turn the slab over and plane the other side. • Tricky Boards: Wildly figured woods are tricky to plane without tearout. Here are a couple tricks to reduce your difficulties with problem woods. When you feed the stock through the planer, try feeding it at an angle, effectively creating a shearing cut. Through the power of geometry, this effectively lowers the cutting angle of your planer's knives, producing a cleaner cut. Another trick is to wet the boards before feeding them through the planer. See the photos on the previous page for more details on this. • Thin Stock: If you need to plane stock down to 1/4n thick or slightly less, you'll need to make a bed board for your planer - essentially an accessory planer bed. Planing thin stock can be tricky. If there's a slight bow, we've seen entire boards disappear into the cutterhead, never to be seen again (until we empty the dust collector, that is). So always make a little extra stock for this operation and make certain it as flat as possible. PW Once both sides of your board have all the rough milling marks removed, you need to flip the board every time it goes through the planer.The object is to remove equal amounts of wood from each side to reduce any warping in the board because of stresses being released in the wood as you plane.To keep the grain direction running the same way, here's how we flip a board: Hold the board in your left hand as if you are going to feed it that way into the planer.With your right hand, slap the front edge of the board downward.Allow the board to twirl in your left hand until the other face is facing up. Feed the board through the planer this way. This method allows you to work fast and reduces the effort needed to flip each board. PLANING 8"-WIDE BOARDS WITH A 6" JOINTER One of the thorniest problems in preparing stock is how to deal with boards that are too wide for your jointer to joint. This trick works with boards that are as wide as 9". A reader showed us this trick and it has become a shop favorite. First remove the guard from your jointer. Surface as much of one side of the board as you can. Make several passes and go to a depth of less than V4". Now get a piece of V4"-thick plywood that is as long as the board you are preparing to plane and 6" wide. Place the plywood in the notch you just jointed and run the two through the planer together with the plywood running against the bed of the planer. Make several passes until the face has been completely planed. Now turn the board over and plane the opposite face.After the rough strip has been removed, continue planing normally until you get to your finished thickness. 92 Popular Woodworking October 2002 |