Popular Woodworking 2003-02 № 132, страница 68

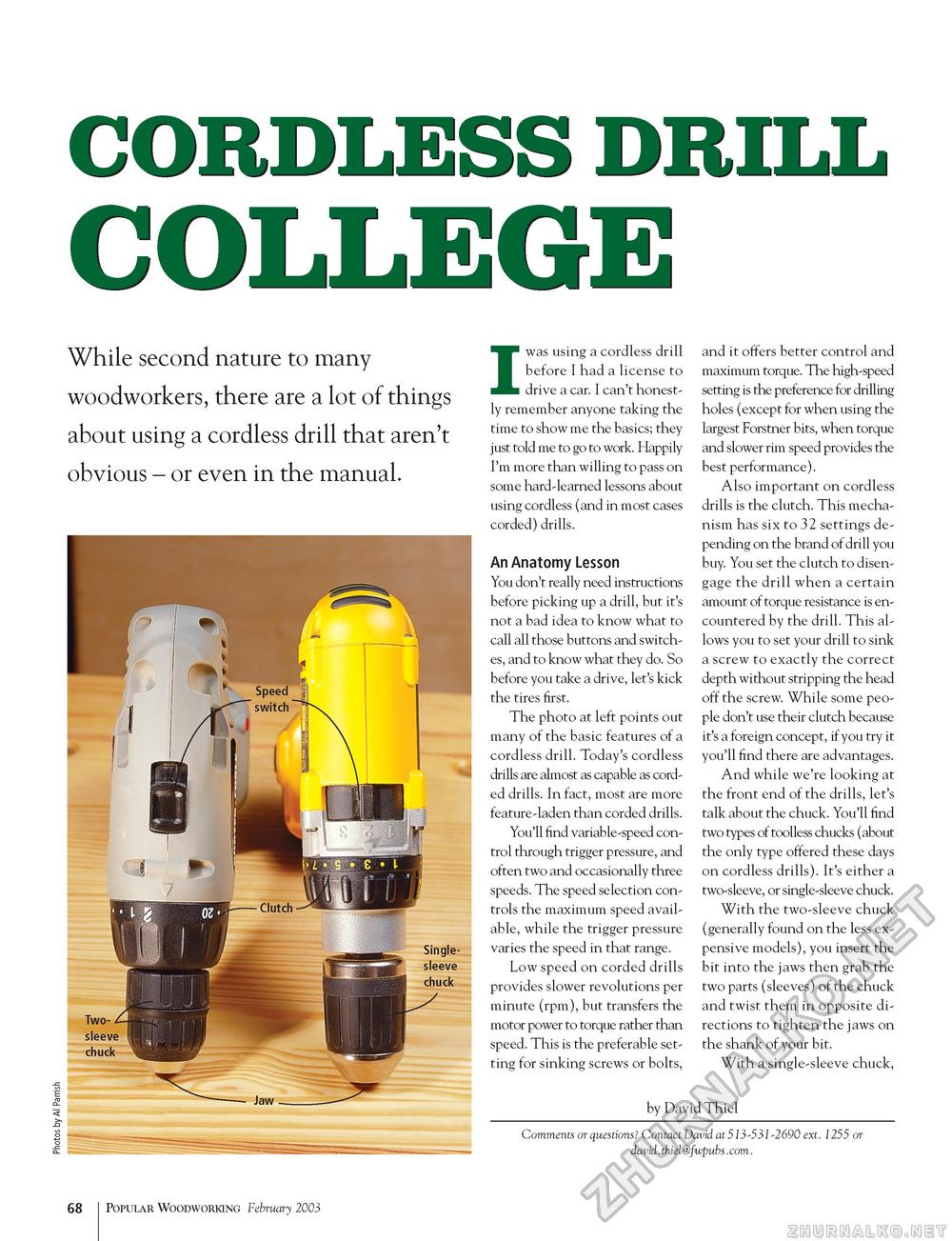

CORDLESS DRILL COLLEGE While second nature to many woodworkers, there are a lot of things about using a cordless drill that aren't obvious - or even in the manual. Iwas using a cordless drill before I had a license to drive a car. I can't honestly remember anyone taking the time to show me the basics; they just told me to go to work. Happily I'm more than willing to pass on some hard-learned lessons about using cordless (and in most cases corded) drills. An Anatomy Lesson You don't really need instructions before picking up a drill, but it's not a bad idea to know what to call all those buttons and switches, and to know what they do. So before you take a drive, let's kick the tires first. The photo at left points out many of the basic features of a cordless drill. Today's cordless drills are almost as capable as corded drills. In fact, most are more feature-laden than corded drills. You'll find variable-speed control through trigger pressure, and often two and occasionally three speeds. The speed selection controls the maximum speed available, while the trigger pressure varies the speed in that range. Low speed on corded drills provides slower revolutions per minute (rpm), but transfers the motor power to torque rather than speed. This is the preferable setting for sinking screws or bolts, and it offers better control and maximum torque. The high-speed setting is the preference for drilling holes (except for when using the largest Forstner bits, when torque and slower rim speed provides the best performance). Also important on cordless drills is the clutch. This mechanism has six to 32 settings depending on the brand of drill you buy. You set the clutch to disengage the drill when a certain amount of torque resistance is encountered by the drill. This allows you to set your drill to sink a screw to exactly the correct depth without stripping the head off the screw. While some people don't use their clutch because it's a foreign concept, if you try it you'll find there are advantages. And while we're looking at the front end of the drills, let's talk about the chuck. You'll find two types of toolless chucks (about the only type offered these days on cordless drills). It's either a two-sleeve, or single-sleeve chuck. With the two-sleeve chuck (generally found on the less expensive models), you insert the bit into the jaws then grab the two parts (sleeves) of the chuck and twist them in opposite directions to tighten the jaws on the shank of your bit. With a single-sleeve chuck, by David Thiel Comments or questions? Contact David at 513-531-2690 ext. 1255 or david.thiel@fwpubs.com. 68 Popular Woodworking February 2003 |