Popular Woodworking 2003-02 № 132, страница 93

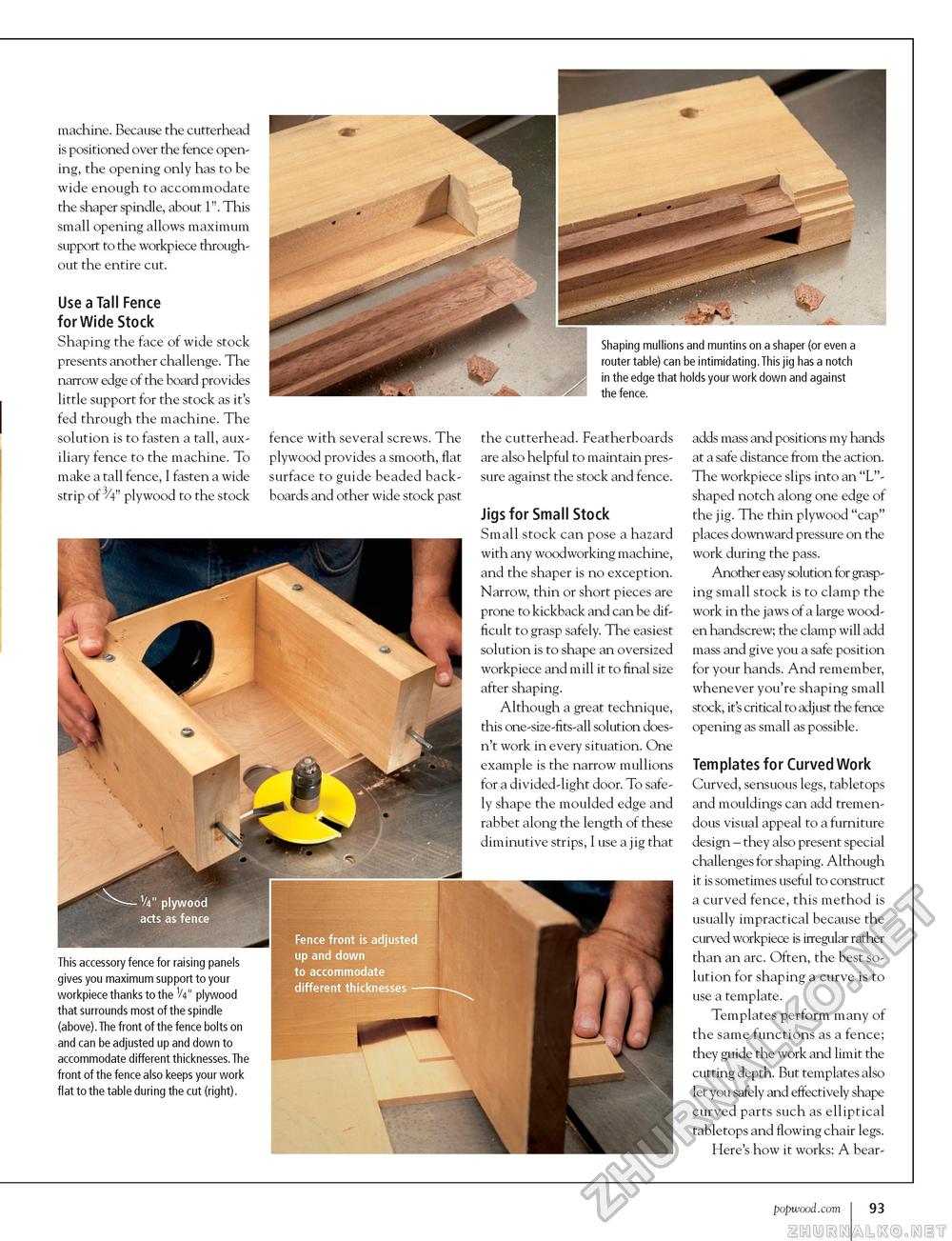

machine. Because the cutterhead is positioned over the fence opening, the opening only has to be wide enough to accommodate the shaper spindle, about 1". This small opening allows maximum support to the workpiece throughout the entire cut. Use a Tall Fence for Wide Stock Shaping the face of wide stock presents another challenge. The narrow edge of the board provides little support for the stock as it's fed through the machine. The solution is to fasten a tall, auxiliary fence to the machine. To make a tall fence, I fasten a wide strip of 3/4" plywood to the stock Shaping mullions and muntins on a shaper (or even a router table) can be intimidating.This jig has a notch in the edge that holds your work down and against the fence. fence with several screws. The plywood provides a smooth, flat surface to guide beaded backboards and other wide stock past the cutterhead. Featherboards are also helpful to maintain pressure against the stock and fence. Jigs for Small Stock Small stock can pose a hazard with any woodworking machine, and the shaper is no exception. Narrow, thin or short pieces are prone to kickback and can be difficult to grasp safely. The easiest solution is to shape an oversized workpiece and mill it to final size after shaping. Although a great technique, this one-size-fits-all solution doesn't work in every situation. One example is the narrow mullions for a divided-light door. To safely shape the moulded edge and rabbet along the length of these diminutive strips, I use a jig that This accessory fence for raising panels gives you maximum support to your workpiece thanks to the V411 plywood that surrounds most of the spindle (above).The front of the fence bolts on and can be adjusted up and down to accommodate different thicknesses. The front of the fence also keeps your work flat to the table during the cut (right). adds mass and positions my hands at a safe distance from the action. The workpiece slips into an "L"-shaped notch along one edge of the jig. The thin plywood "cap" places downward pressure on the work during the pass. Another easy solution for grasping small stock is to clamp the work in the jaws of a large wooden handscrew; the clamp will add mass and give you a safe position for your hands. And remember, whenever you're shaping small stock, it's critical to adjust the fence opening as small as possible. Templates for Curved Work Curved, sensuous legs, tabletops and mouldings can add tremendous visual appeal to a furniture design - they also present special challenges for shaping. Although it is sometimes useful to construct a curved fence, this method is usually impractical because the curved workpiece is irregular rather than an arc. Often, the best solution for shaping a curve is to use a template. Templates perform many of the same functions as a fence; they guide the work and limit the cutting depth. But templates also let you safely and effectively shape curved parts such as elliptical tabletops and flowing chair legs. Here's how it works: A bear- popwood.com 93 |