Popular Woodworking 2003-06 № 134, страница 39

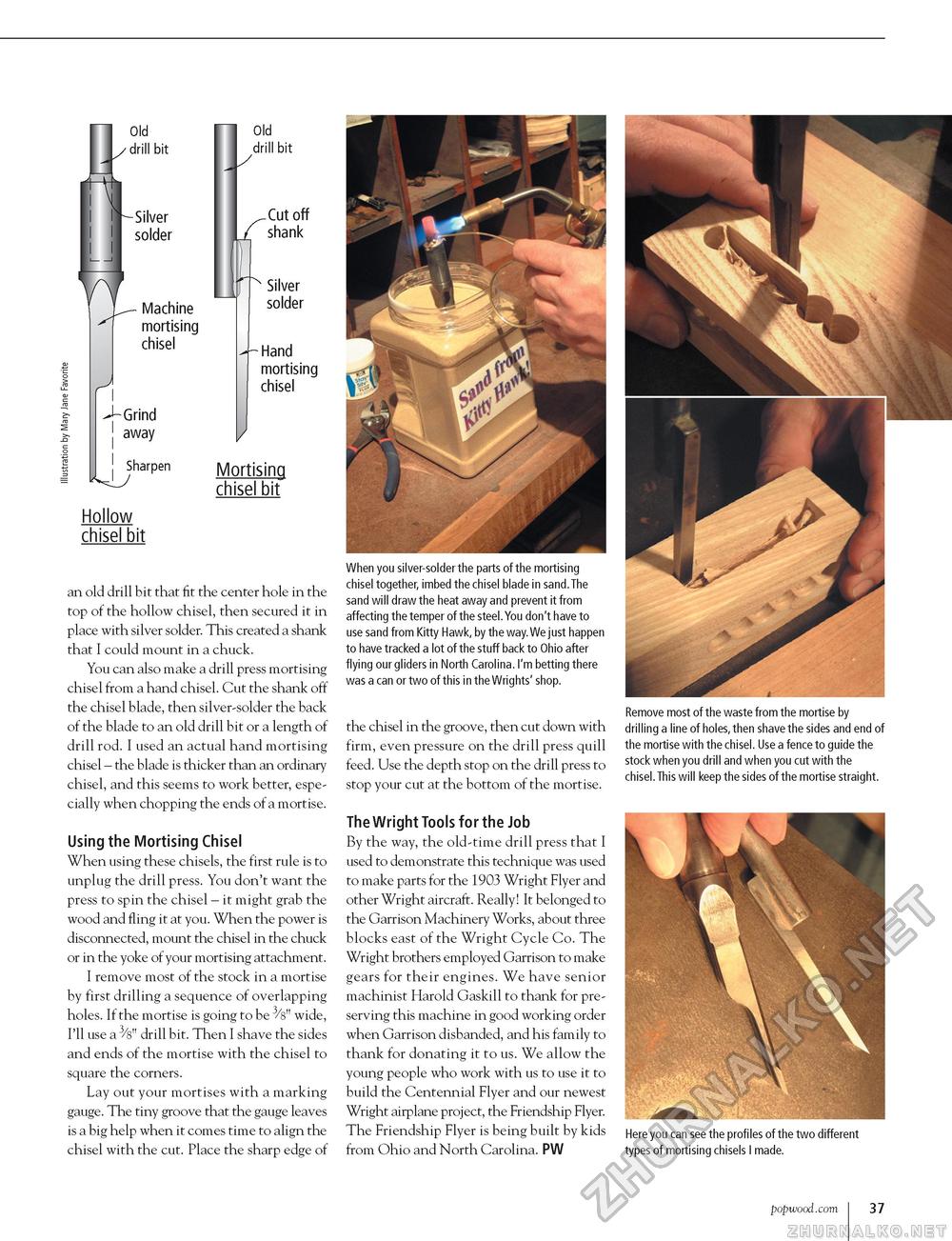

Old 'drill bit Silver solder Machine mortising chisel I Grind j away ' Sharpen Old drill bit Cut off f shank Silver solder Hand mortising chisel Mortising chisel bit Hollow chisel bit an old drill bit that fit the center hole in the top of the hollow chisel, then secured it in place with silver solder. This created a shank that I could mount in a chuck. You can also make a drill press mortising chisel from a hand chisel. Cut the shank off the chisel blade, then silver-solder the back of the blade to an old drill bit or a length of drill rod. I used an actual hand mortising chisel - the blade is thicker than an ordinary chisel, and this seems to work better, especially when chopping the ends of a mortise. Using the Mortising Chisel When using these chisels, the first rule is to unplug the drill press. You don't want the press to spin the chisel - it might grab the wood and fling it at you. When the power is disconnected, mount the chisel in the chuck or in the yoke of your mortising attachment. I remove most of the stock in a mortise by first drilling a sequence of overlapping holes. If the mortise is going to be 3/s" wide, I'll use a 3/8" drill bit. Then I shave the sides and ends of the mortise with the chisel to square the corners. Lay out your mortises with a marking gauge. The tiny groove that the gauge leaves is a big help when it comes time to align the chisel with the cut. Place the sharp edge of the chisel in the groove, then cut down with firm, even pressure on the drill press quill feed. Use the depth stop on the drill press to stop your cut at the bottom of the mortise. The Wright Tools for the Job By the way, the old-time drill press that I used to demonstrate this technique was used to make parts for the 1903 Wright Flyer and other Wright aircraft. Really! It belonged to the Garrison Machinery Works, about three blocks east of the Wright Cycle Co. The Wright brothers employed Garrison to make gears for their engines. We have senior machinist Harold Gaskill to thank for preserving this machine in good working order when Garrison disbanded, and his family to thank for donating it to us. We allow the young people who work with us to use it to build the Centennial Flyer and our newest Wright airplane project, the Friendship Flyer. The Friendship Flyer is being built by kids from Ohio and North Carolina. PW Remove most of the waste from the mortise by drilling a line of holes, then shave the sides and end of the mortise with the chisel. Use a fence to guide the stock when you drill and when you cut with the chisel.This will keep the sides of the mortise straight. Here you can see the profiles of the two different types of mortising chisels I made. popwood.com 37 |