Popular Woodworking 2003-08 № 135, страница 20

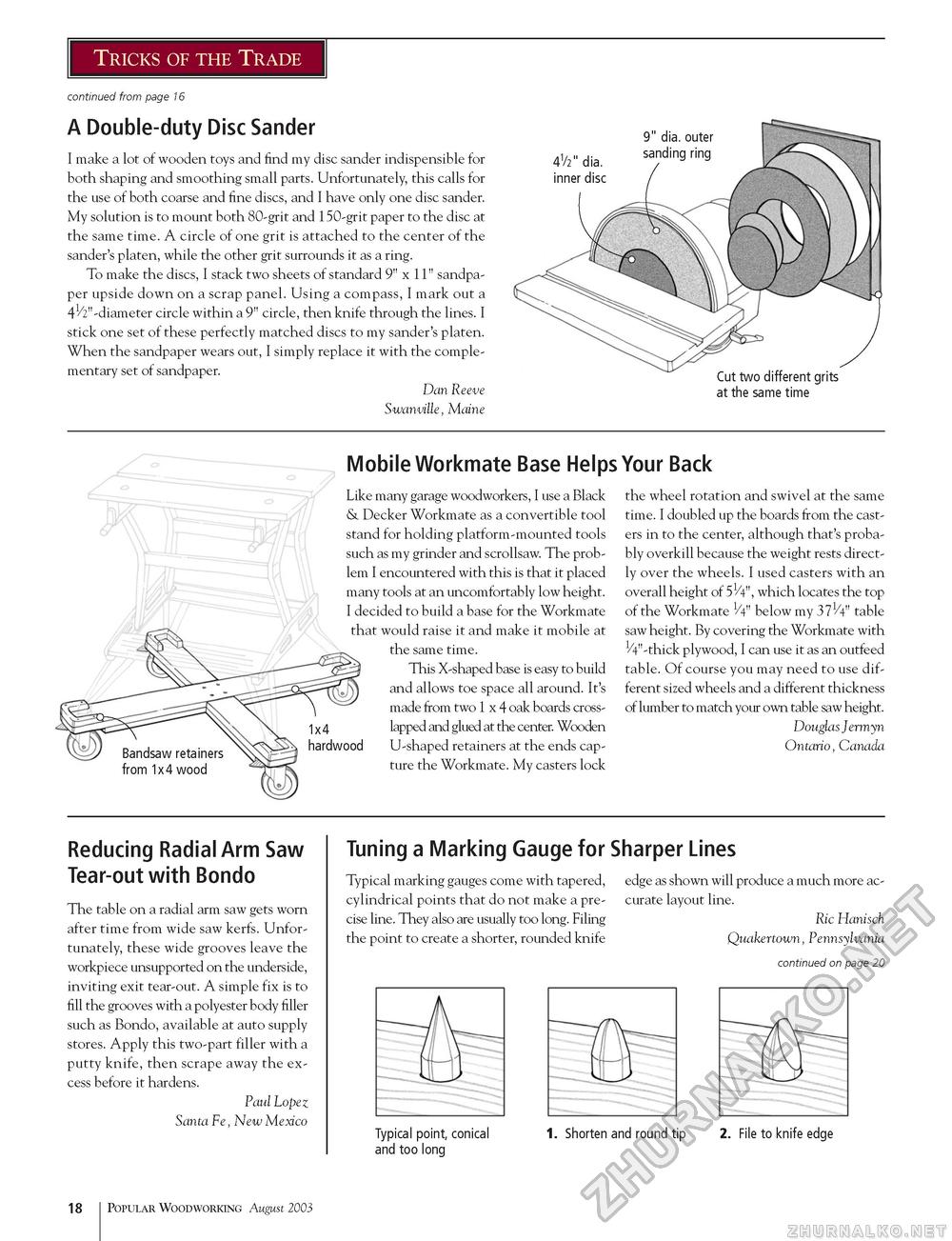

Tricks of the Trade continued from page 16 A Double-duty Disc Sander I make a lot of wooden toys and find my disc sander indispensible for both shaping and smoothing small parts. Unfortunately, this calls for the use of both coarse and fine discs, and I have only one disc sander. My solution is to mount both 80-grit and 150-grit paper to the disc at the same time. A circle of one grit is attached to the center of the sander's platen, while the other grit surrounds it as a ring. To make the discs, I stack two sheets of standard 9" x 11" sandpaper upside down on a scrap panel. Using a compass, I mark out a 41/2" -diameter circle within a 9" circle, then knife through the lines. I stick one set of these perfectly matched discs to my sander's platen. When the sandpaper wears out, I simply replace it with the complementary set of sandpaper. Dan Reeve Swanville, Maine Mobile Workmate Base Helps Your Back Bandsaw retainers from 1x4 wood Like many garage woodworkers, I use a Black & Decker Workmate as a convertible tool stand for holding platform-mounted tools such as my grinder and scrollsaw. The problem I encountered with this is that it placed many tools at an uncomfortably low height. I decided to build a base for the Workmate that would raise it and make it mobile at the same time. This X-shaped base is easy to build . M and allows toe space all around. It's made from two 1 x 4 oak boards cross-1 x 4 lapped and glued at the center. Wooden hardwood U-shaped retainers at the ends capture the Workmate. My casters lock the wheel rotation and swivel at the same time. I doubled up the boards from the casters in to the center, although that's probably overkill because the weight rests directly over the wheels. I used casters with an overall height of 51/4", which locates the top of the Workmate 1/4" below my 371/4" table saw height. By covering the Workmate with 1/4"-thick plywood, I can use it as an outfeed table. Of course you may need to use different sized wheels and a different thickness of lumber to match your own table saw height. Douglas Jermyn Ontario, Canada Reducing Radial Arm Saw Tear-out with Bondo The table on a radial arm saw gets worn after time from wide saw kerfs. Unfortunately, these wide grooves leave the workpiece unsupported on the underside, inviting exit tear-out. A simple fix is to fill the grooves with a polyester body filler such as Bondo, available at auto supply stores. Apply this two-part filler with a putty knife, then scrape away the excess before it hardens. Paul Lopez Santa Fe, New Mexico Tuning a Marking Gauge for Sharper Lines Typical marking gauges come with tapered, cylindrical points that do not make a precise line. They also are usually too long. Filing the point to create a shorter, rounded knife edge as shown will produce a much more accurate layout line. Ric Hanisch Quakertown, Pennsylvania continued on page 20 and too long 18 Popular Woodworking August 2003 |