Popular Woodworking 2003-08 № 135, страница 22

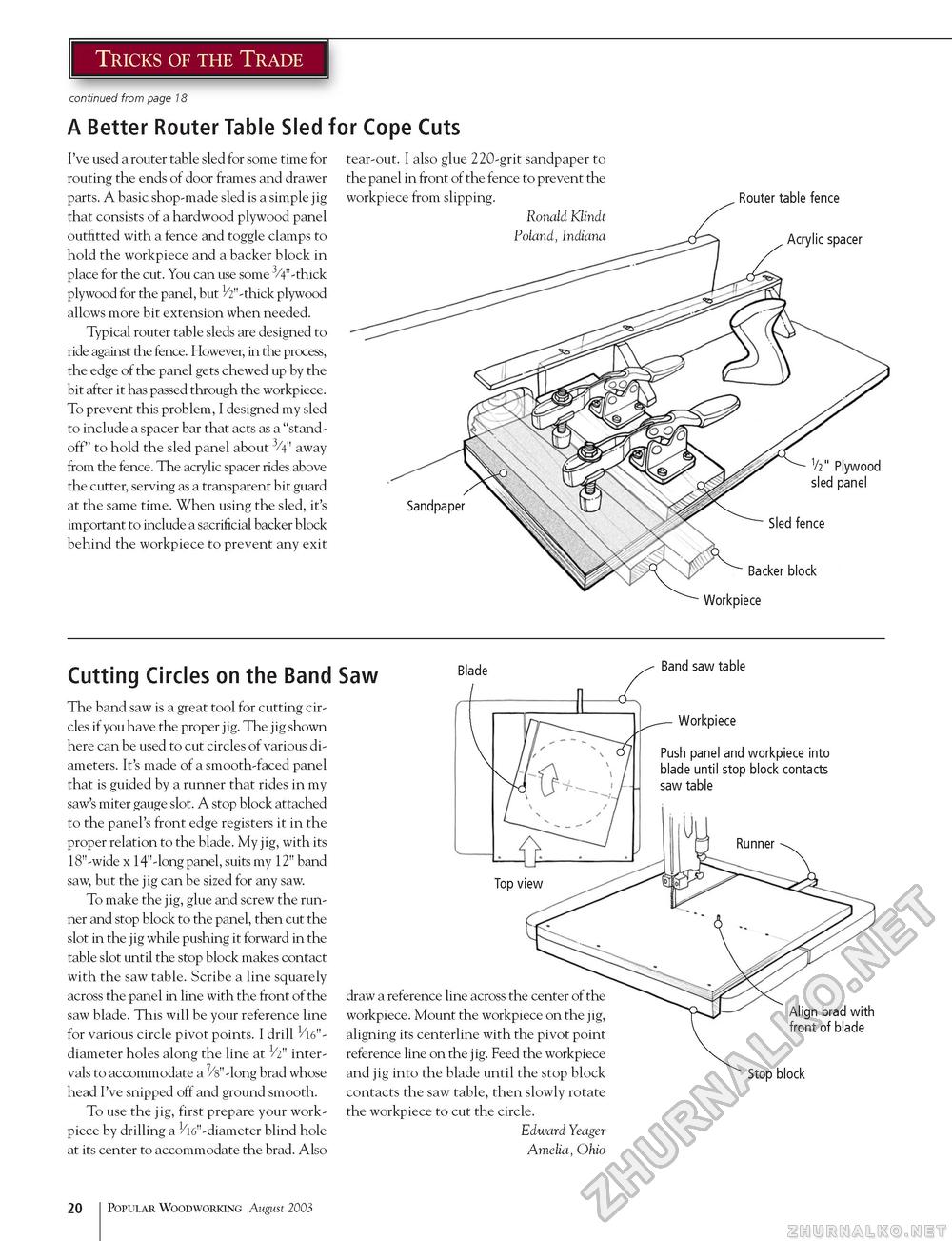

A Better Router Table Sled for Cope Cuts I've used a router table sled for some time for routing the ends of door frames and drawer parts. A basic shop-made sled is a simple jig that consists of a hardwood plywood panel outfitted with a fence and toggle clamps to hold the workpiece and a backer block in place for the cut. You can use some 3/4"-thick plywood for the panel, but 1/2"-thick plywood allows more bit extension when needed. Typical router table sleds are designed to ride against the fence. However, in the process, the edge of the panel gets chewed up by the bit after it has passed through the workpiece. To prevent this problem, I designed my sled to include a spacer bar that acts as a "standoff" to hold the sled panel about 3/4" away from the fence. The acrylic spacer rides above the cutter, serving as a transparent bit guard at the same time. When using the sled, it's important to include a sacrificial backer block behind the workpiece to prevent any exit tear-out. I also glue 220-grit sandpaper to the panel in front of the fence to prevent the workpiece from slipping. Cutting Circles on the Band Saw The band saw is a great tool for cutting circles if you have the proper jig. The jig shown here can be used to cut circles of various diameters. It's made of a smooth-faced panel that is guided by a runner that rides in my saw's miter gauge slot. A stop block attached to the panel's front edge registers it in the proper relation to the blade. My jig, with its 18"-wide x 14"-long panel, suits my 12" band saw, but the jig can be sized for any saw. To make the jig, glue and screw the runner and stop block to the panel, then cut the slot in the jig while pushing it forward in the table slot until the stop block makes contact with the saw table. Scribe a line squarely across the panel in line with the front of the saw blade. This will be your reference line for various circle pivot points. I drill 1/16"-diameter holes along the line at 1/2" intervals to accommodate a 7/8"-long brad whose head I've snipped off and ground smooth. To use the jig, first prepare your work-piece by drilling a 1/16" -diameter blind hole at its center to accommodate the brad. Also Blade Band saw table Workpiece Push panel and workpiece into blade until stop block contacts saw table draw a reference line across the center of the workpiece. Mount the workpiece on the jig, aligning its centerline with the pivot point reference line on the jig. Feed the workpiece and jig into the blade until the stop block contacts the saw table, then slowly rotate the workpiece to cut the circle. Edward Yeager Amelia, Ohio Align brad with front of blade Stop block 20 Popular Woodworking August 2003 |