Popular Woodworking 2003-11 № 137, страница 21

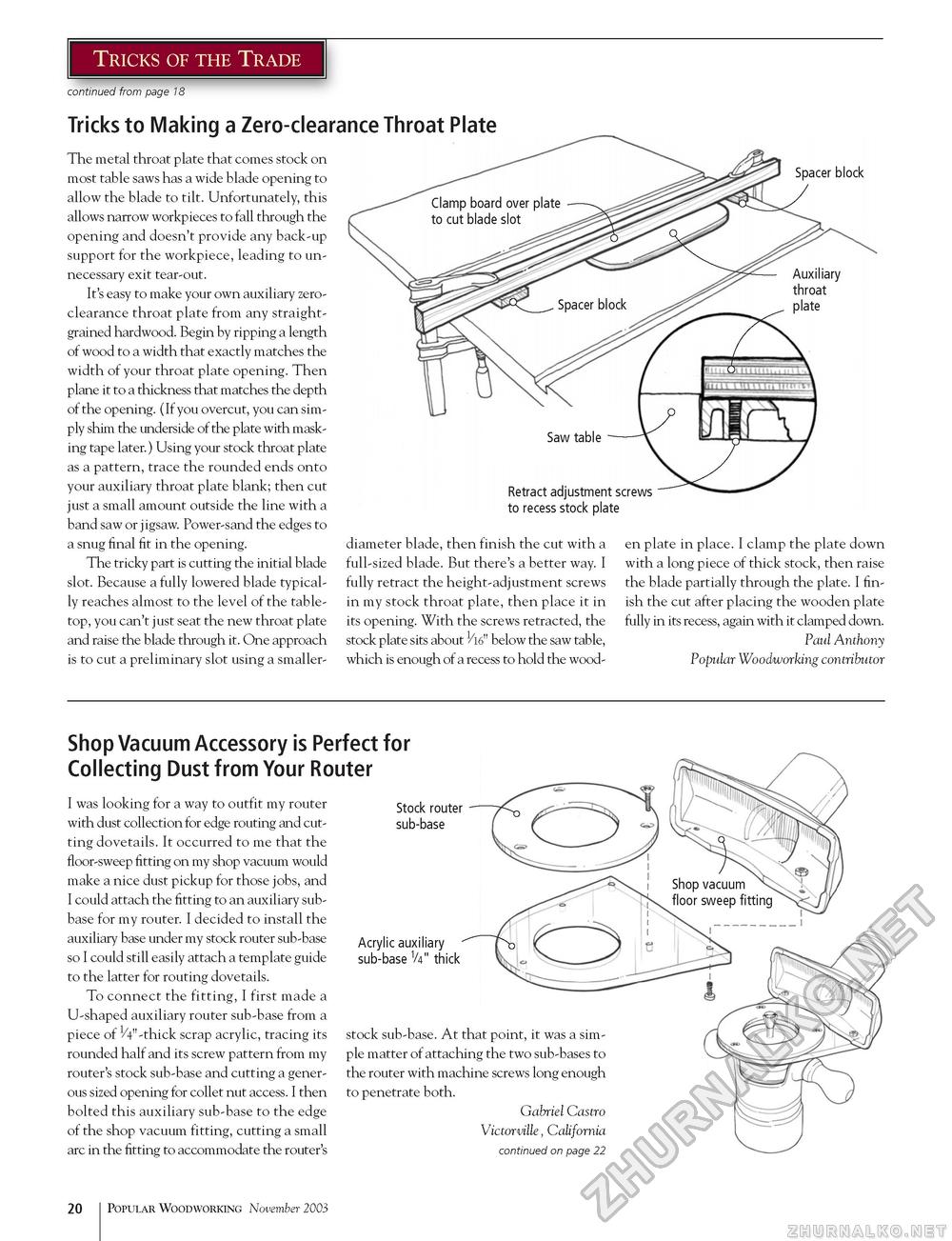

Tricks of the Trade continued from page 18 Tricks to Making a Zero-clearance Throat Plate Spacer block Retract adjustment screws to recess stock plate The metal throat plate that comes stock on most table saws has a wide blade opening to allow the blade to tilt. Unfortunately, this allows narrow workpieces to fall through the opening and doesn't provide any back-up support for the workpiece, leading to unnecessary exit tear-out. It's easy to make your own auxiliary zero-clearance throat plate from any straight-grained hardwood. Begin by ripping a length of wood to a width that exactly matches the width of your throat plate opening. Then plane it to a thickness that matches the depth of the opening. (If you overcut, you can simply shim the underside of the plate with masking tape later.) Using your stock throat plate as a pattern, trace the rounded ends onto your auxiliary throat plate blank; then cut just a small amount outside the line with a band saw or jigsaw. Power-sand the edges to a snug final fit in the opening. The tricky part is cutting the initial blade slot. Because a fully lowered blade typically reaches almost to the level of the table-top, you can't just seat the new throat plate and raise the blade through it. One approach is to cut a preliminary slot using a smaller- diameter blade, then finish the cut with a full-sized blade. But there's a better way. I fully retract the height-adjustment screws in my stock throat plate, then place it in its opening. With the screws retracted, the stock plate sits about ^V below the saw table, which is enough of a recess to hold the wood- en plate in place. I clamp the plate down with a long piece of thick stock, then raise the blade partially through the plate. I finish the cut after placing the wooden plate fully in its recess, again with it clamped down. Paul Anthony Popular Woodworking contributor Shop Vacuum Accessory is Perfect for Collecting Dust from Your Router I was looking for a way to outfit my router with dust collection for edge routing and cutting dovetails. It occurred to me that the floor-sweep fitting on my shop vacuum would make a nice dust pickup for those jobs, and I could attach the fitting to an auxiliary sub-base for my router. I decided to install the auxiliary base under my stock router sub-base so I could still easily attach a template guide to the latter for routing dovetails. To connect the fitting, I first made a U-shaped auxiliary router sub-base from a piece of 1/4"-thick scrap acrylic, tracing its rounded half and its screw pattern from my router's stock sub-base and cutting a generous sized opening for collet nut access. I then bolted this auxiliary sub-base to the edge of the shop vacuum fitting, cutting a small arc in the fitting to accommodate the router's Stock router sub-base Shop vacuum floor sweep fitting Acrylic auxiliary sub-base V4" thick stock sub-base. At that point, it was a simple matter of attaching the two sub-bases to the router with machine screws long enough to penetrate both. Gabriel Castro Victorville, California continued on page 22 20 Popular Woodworking November 2003 |