Popular Woodworking 2003-11 № 137, страница 82

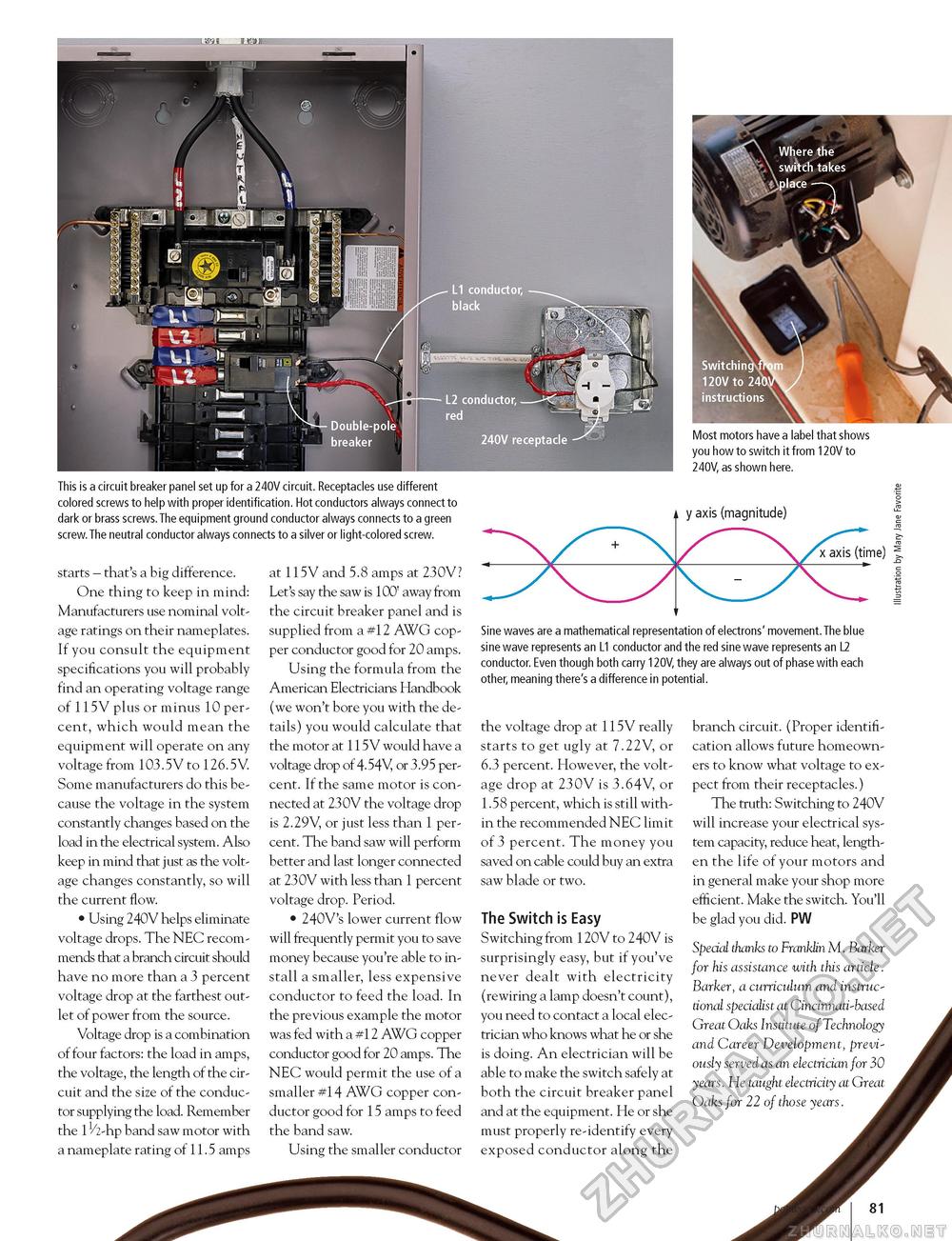

Most motors have a label that shows you how to switch it from 120V to 240V, as shown here. This is a circuit breaker panel set up for a 240V circuit. Receptacles use different colored screws to help with proper identification. Hot conductors always connect to dark or brass screws.The equipment ground conductor always connects to a green screw. The neutral conductor always connects to a silver or light-colored screw. y axis (magnitude) x axis (time) starts - that's a big difference. One thing to keep in mind: Manufacturers use nominal voltage ratings on their nameplates. If you consult the equipment specifications you will probably find an operating voltage range of 115V plus or minus 10 percent, which would mean the equipment will operate on any voltage from 103.5V to 126.5V. Some manufacturers do this because the voltage in the system constantly changes based on the load in the electrical system. Also keep in mind that just as the voltage changes constantly, so will the current flow. • Using 240V helps eliminate voltage drops. The NEC recommends that a branch circuit should have no more than a 3 percent voltage drop at the farthest outlet of power from the source. Voltage drop is a combination of four factors: the load in amps, the voltage, the length of the circuit and the size of the conductor supplying the load. Remember the 11/2-hp band saw motor with a nameplate rating of 11.5 amps at 115V and 5.8 amps at 230V? Let's say the saw is 100' away from the circuit breaker panel and is supplied from a #12 AWG copper conductor good for 20 amps. Using the formula from the American Electricians Handbook (we won't bore you with the details) you would calculate that the motor at 115V would have a voltage drop of 4.54V or 3.95 percent. If the same motor is connected at 230V the voltage drop is 2.29V, or just less than 1 percent. The band saw will perform better and last longer connected at 230V with less than 1 percent voltage drop. Period. • 240V's lower current flow will frequently permit you to save money because you're able to install a smaller, less expensive conductor to feed the load. In the previous example the motor was fed with a #12 AWG copper conductor good for 20 amps. The NEC would permit the use of a smaller #14 AWG copper conductor good for 15 amps to feed the band saw. Using the smaller conductor Sine waves are a mathematical representation of electrons' movement. The blue sine wave represents an L1 conductor and the red sine wave represents an L2 conductor. Even though both carry 120V, they are always out of phase with each other, meaning there's a difference in potential. the voltage drop at 115V really starts to get ugly at 7.22 V, or 6.3 percent. However, the voltage drop at 230V is 3.64 V, or 1.58 percent, which is still within the recommended NEC limit of 3 percent. The money you saved on cable could buy an extra saw blade or two. The Switch is Easy Switching from 120V to 240V is surprisingly easy, but if you've never dealt with electricity (rewiring a lamp doesn't count), you need to contact a local electrician who knows what he or she is doing. An electrician will be able to make the switch safely at both the circuit breaker panel and at the equipment. He or she must properly re-identify every exposed conductor along the branch circuit. (Proper identification allows future homeowners to know what voltage to expect from their receptacles.) The truth: Switching to 240V will increase your electrical system capacity, reduce heat, lengthen the life of your motors and in general make your shop more efficient. Make the switch. You'll be glad you did. PW Special thanks to Franklin M. Barker for his assistance with this article. Barker, a curriculum and instructional specialist at Cincinnati-based Great Oaks Institute of Technology and Career Development, previously served as an electrician for 30 years. He taught electricity at Great Oaks for 22 of those years. 81 |