Popular Woodworking 2003-11 № 137, страница 81

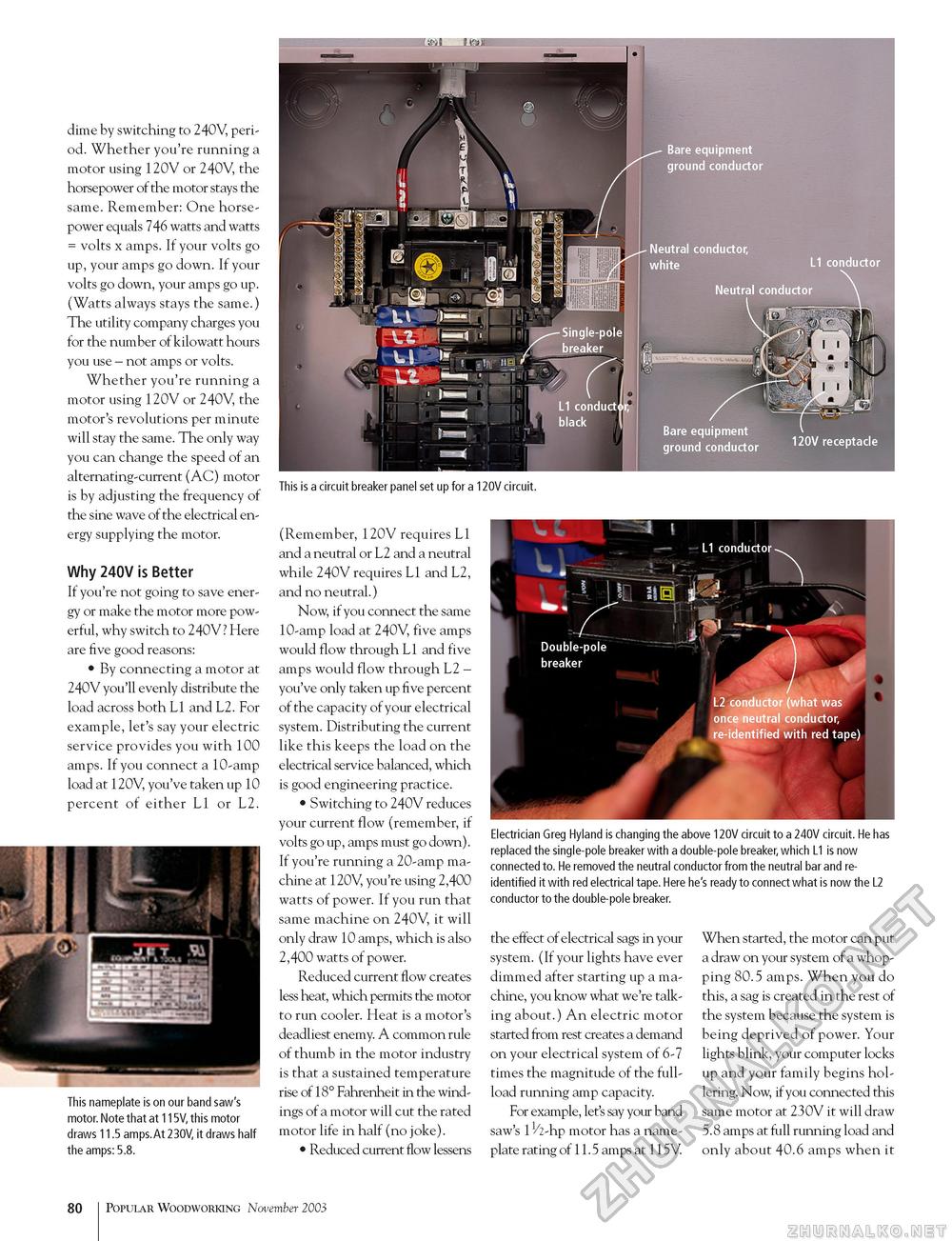

dime by switching to 240V, period. Whether you're running a motor using 120V or 240V, the horsepower of the motor stays the same. Remember: One horsepower equals 746 watts and watts = volts x amps. If your volts go up, your amps go down. If your volts go down, your amps go up. (Watts always stays the same.) The utility company charges you for the number of kilowatt hours you use - not amps or volts. Whether you're running a motor using 120V or 240V, the motor's revolutions per minute will stay the same. The only way you can change the speed of an alternating-current (AC) motor is by adjusting the frequency of the sine wave of the electrical energy supplying the motor. Why 240V is Better If you're not going to save energy or make the motor more powerful, why switch to 240V? Here are five good reasons: • By connecting a motor at 240V you'll evenly distribute the load across both L1 and L2. For example, let's say your electric service provides you with 100 amps. If you connect a 10-amp load at 120V, you've taken up 10 percent of either L1 or L2. This nameplate is on our band saw's motor. Note that at 115V, this motor draws 11.5 amps.At 230V, it draws half the amps: 5.8. This is a circuit breaker panel set up for a 120V circuit. J t s— — L1 conductor 1 ! £ m m Double-pole breaker [ -m, L2 conductor (what was once neutral conductor, re-identified with red tape) Electrician Greg Hyland is changing the above 120V circuit to a 240V circuit. He has replaced the single-pole breaker with a double-pole breaker, which L1 is now connected to. He removed the neutral conductor from the neutral bar and re-identified it with red electrical tape. Here he's ready to connect what is now the L2 conductor to the double-pole breaker. (Remember, 120V requires L1 and a neutral or L2 and a neutral while 240V requires L1 and L2, and no neutral.) Now, if you connect the same 10-amp load at 240V, five amps would flow through L1 and five amps would flow through L2 -you've only taken up five percent of the capacity of your electrical system. Distributing the current like this keeps the load on the electrical service balanced, which is good engineering practice. • Switching to 240V reduces your current flow (remember, if volts go up, amps must go down). If you're running a 20-amp machine at 120V, you're using 2,400 watts of power. If you run that same machine on 240V, it will only draw 10 amps, which is also 2,400 watts of power. Reduced current flow creates less heat, which permits the motor to run cooler. Heat is a motor's deadliest enemy. A common rule of thumb in the motor industry is that a sustained temperature rise of 18° Fahrenheit in the windings of a motor will cut the rated motor life in half (no joke). • Reduced current flow lessens the effect of electrical sags in your system. (If your lights have ever dimmed after starting up a machine, you know what we're talking about.) An electric motor started from rest creates a demand on your electrical system of 6-7 times the magnitude of the full-load running amp capacity. For example, let's say your band saw's 11/2-hp motor has a name-plate rating of 11.5 amps at 115V. When started, the motor can put a draw on your system of a whopping 80.5 amps. When you do this, a sag is created in the rest of the system because the system is being deprived of power. Your lights blink, your computer locks up and your family begins hollering. Now, if you connected this same motor at 230V it will draw 5.8 amps at full running load and only about 40.6 amps when it 80 Popular Woodworking November 2003 |