Popular Woodworking 2003-12 № 138, страница 24

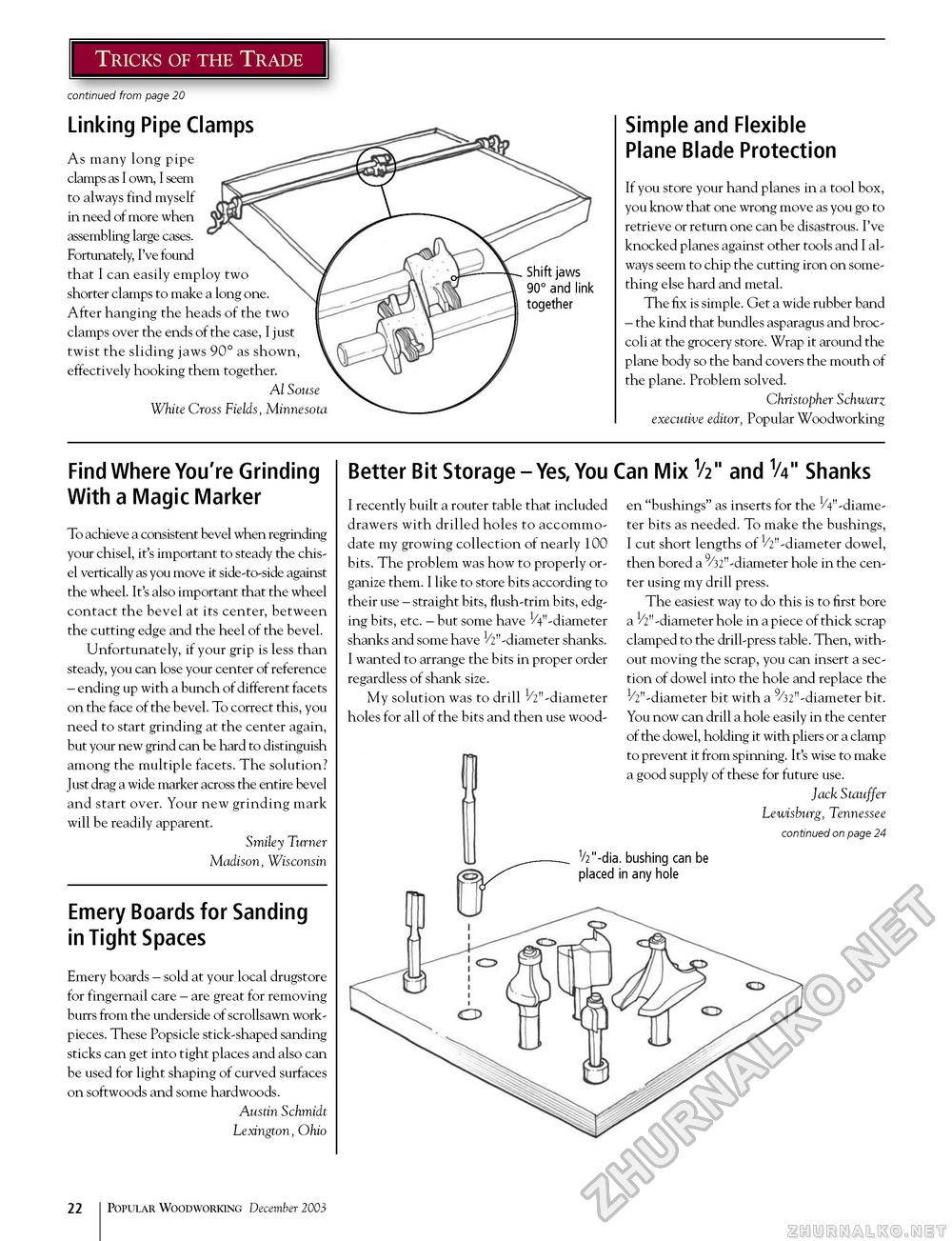

Linking Pipe Clamps As many long pipe clamps as I own, I seem to always find myself in need of more when assembling large cases. Fortunately, I've found that I can easily employ two shorter clamps to make a long one. After hanging the heads of the two clamps over the ends of the case, I just twist the sliding jaws 90° as shown effectively hooking them together. Al Souse White Cross Fields, Minnesota Shift jaws 90° and link together Simple and Flexible Plane Blade Protection If you store your hand planes in a tool box, you know that one wrong move as you go to retrieve or return one can be disastrous. I've knocked planes against other tools and I always seem to chip the cutting iron on something else hard and metal. The fix is simple. Get a wide rubber band - the kind that bundles asparagus and broccoli at the grocery store. Wrap it around the plane body so the band covers the mouth of the plane. Problem solved. Christopher Schwarz executive editor, Popular Woodworking Find Where You're Grinding With a Magic Marker To achieve a consistent bevel when regrinding your chisel, it's important to steady the chisel vertically as you move it side-to-side against the wheel. It's also important that the wheel contact the bevel at its center, between the cutting edge and the heel of the bevel. Unfortunately, if your grip is less than steady, you can lose your center of reference - ending up with a bunch of different facets on the face of the bevel. To correct this, you need to start grinding at the center again, but your new grind can be hard to distinguish among the multiple facets. The solution? Just drag a wide marker across the entire bevel and start over. Your new grinding mark will be readily apparent. Smiley Turner Madison, Wisconsin Emery Boards for Sanding in Tight Spaces Emery boards - sold at your local drugstore for fingernail care - are great for removing burrs from the underside of scrollsawn work-pieces. These Popsicle stick-shaped sanding sticks can get into tight places and also can be used for light shaping of curved surfaces on softwoods and some hardwoods. Austin Schmidt Lexngton, Ohio Better Bit Storage - Yes, You I recently built a router table that included drawers with drilled holes to accommodate my growing collection of nearly 100 bits. The problem was how to properly organize them. I like to store bits according to their use - straight bits, flush-trim bits, edging bits, etc. - but some have ^"-diameter shanks and some have ^"-diameter shanks. I wanted to arrange the bits in proper order regardless of shank size. My solution was to drill 1/2" -diameter holes for all of the bits and then use wood- 0 Can Mix V2" and V4" Shanks en "bushings" as inserts for the 1/4"-diame-ter bits as needed. To make the bushings, I cut short lengths of ^"-diameter dowel, then bored a 9/32" -diameter hole in the center using my drill press. The easiest way to do this is to first bore a 1/2"-diameter hole in a piece of thick scrap clamped to the drill-press table. Then, without moving the scrap, you can insert a section of dowel into the hole and replace the 1/2"-diameter bit with a 9/32" -diameter bit. You now can drill a hole easily in the center of the dowel, holding it with pliers or a clamp to prevent it from spinning. It's wise to make a good supply of these for future use. Jack Stauffer Lewisburg, Tennessee continued on page 24 72 Popular Woodworking December 2003 |