Popular Woodworking 2003-12 № 138, страница 22

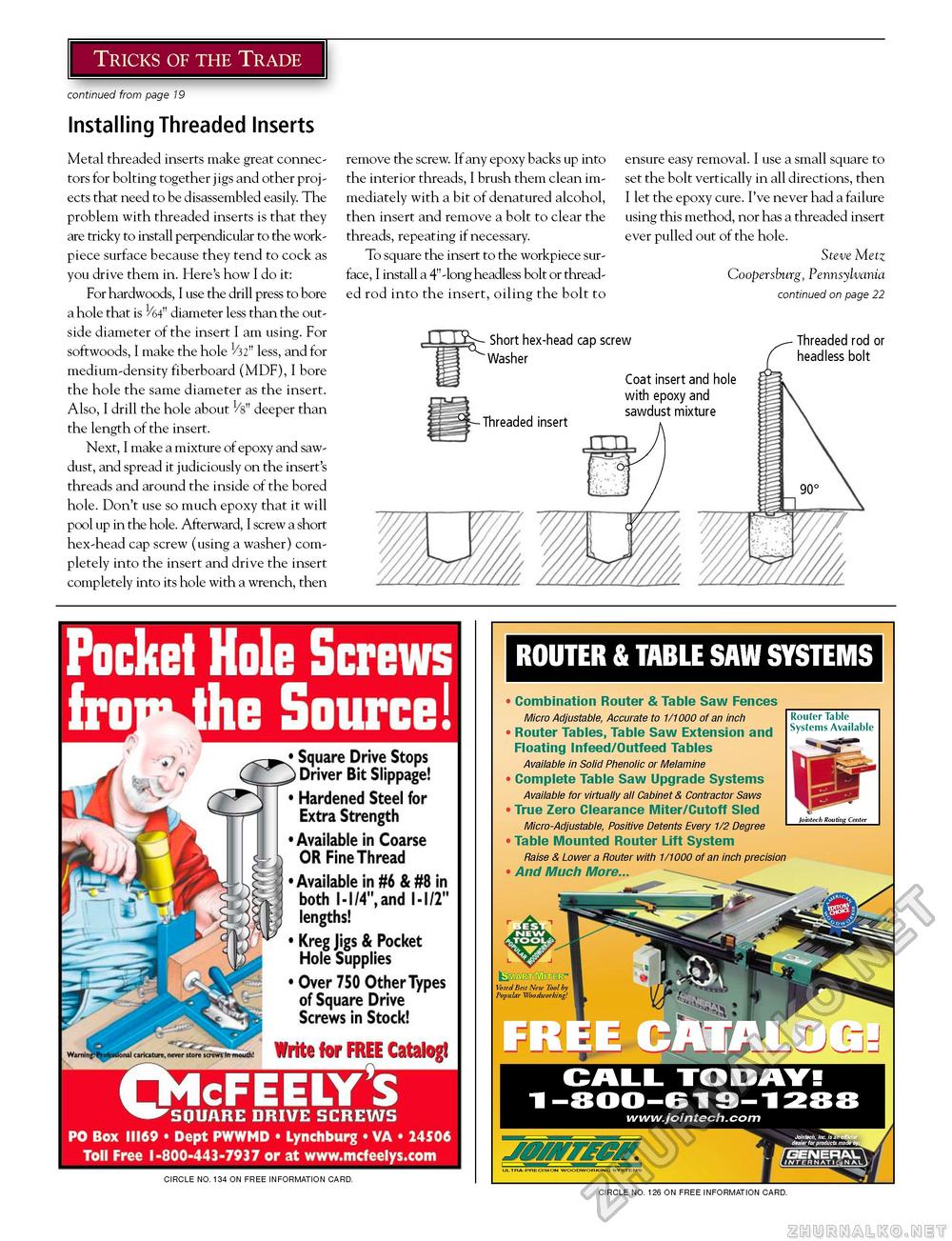

Tricks of the Trade continued from page 19 Installing Threaded Inserts Metal threaded inserts make great connectors for bolting together jigs and other projects that need to be disassembled easily. The problem with threaded inserts is that they are tricky to install perpendicular to the work-piece surface because they tend to cock as you drive them in. Here's how I do it: For hardwoods, I use the drill press to bore a hole that is 1/64" diameter less than the outside diameter of the insert I am using. For softwoods, I make the hole 1/32" less, and for medium-density fiberboard (MDF), I bore the hole the same diameter as the insert. Also, I drill the hole about Vs" deeper than the length of the insert. Next, I make a mixture of epoxy and sawdust, and spread it judiciously on the insert's threads and around the inside of the bored hole. Don't use so much epoxy that it will pool up in the hole. Afterward, I screw a short hex-head cap screw (using a washer) completely into the insert and drive the insert completely into its hole with a wrench, then remove the screw. If any epoxy backs up into the interior threads, I brush them clean immediately with a bit of denatured alcohol, then insert and remove a bolt to clear the threads, repeating if necessary. To square the insert to the workpiece surface, I install a 4"-long headless bolt or threaded rod into the insert, oiling the bolt to ensure easy removal. I use a small square to set the bolt vertically in all directions, then I let the epoxy cure. I've never had a failure using this method, nor has a threaded insert ever pulled out of the hole. Steve Metz Coopersburg, Pennsylvania continued on page 22 Short hex-head cap screw Washer Threaded rod or headless bolt Threaded insert Coat insert and hole with epoxy and sawdust mixture Pocket Hole Screws frouklhe Source! CIRCLE NO. 100 ON FREE INFORMATION CARD. ROUTER & TABLE SAW SYSTEMS Combination Router & Table Saw Fences Micro Adjustable, Accurate to 1/1000 of an inch Router Tables, Table Saw Extension and Floating Infeed/Outfeed Tables Available in Solid Phenolic or Melamine Complete Table Saw Upgrade Systems Available for virtually all Cabinet & Contractor Saws True Zero Clearance Miter/Cutoff Sled Micro-Adjustable, Positive Detents Every 1/2 Degree Table Mounted Router Lift System Raise &Lower a Router with 1/1000 of an inch precision ' And Much More... Router Table Systems Available CIRCLE NO. 126 ON FREE INFORMATION CARD. |