Popular Woodworking 2003-12 № 138, страница 62

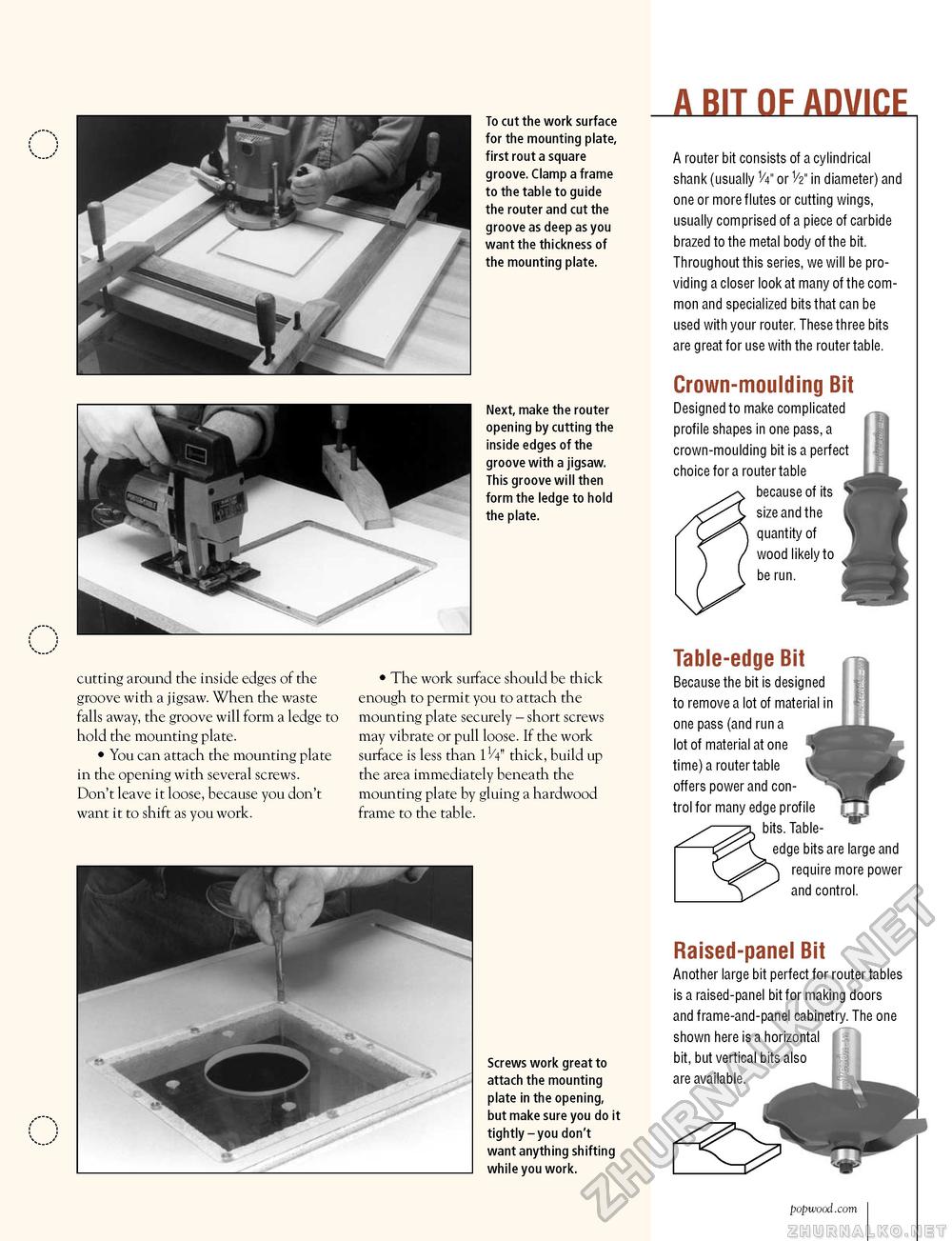

To cut the work surface for the mounting plate, first rout a square groove. Clamp a frame to the table to guide the router and cut the groove as deep as you want the thickness of the mounting plate. Next, make the router opening by cutting the inside edges of the groove with a jigsaw. This groove will then form the ledge to hold the plate. cutting around the inside edges of the groove with a jigsaw. When the waste falls away, the groove will form a ledge to hold the mounting plate. • You can attach the mounting plate in the opening with several screws. Don't leave it loose, because you don't want it to shift as you work. • The work surface should be thick enough to permit you to attach the mounting plate securely - short screws may vibrate or pull loose. If the work surface is less than 11/4" thick, build up the area immediately beneath the mounting plate by gluing a hardwood frame to the table. Screws work great to attach the mounting plate in the opening, but make sure you do it tightly - you don't want anything shifting while you work. A BIT OF ADVICE A router bit consists of a cylindrical shank (usually V4" or 1/2" in diameter) and one or more flutes or cutting wings, usually comprised of a piece of carbide brazed to the metal body of the bit. Throughout this series, we will be providing a closer look at many of the common and specialized bits that can be used with your router. These three bits are great for use with the router table. Crown-moulding Bit Designed to make complicated profile shapes in one pass, a crown-moulding bit is a perfect choice for a router table because of its size and the quantity of wood likely to be run. Table-edge Bit Because the bit is designed to remove a lot of material in one pass (and run a lot of material at one time) a router table M offers power and control for many edge profile bits. Table-edge bits are large and require more power and control. Raised-panel Bit Another large bit perfect for router tables is a raised-panel bit for making doors and frame-and-panel cabinetry. The one shown here is a horizontal bit, but vertical bits also are available. popwood.com 73 |