Popular Woodworking 2004-02 № 139, страница 36

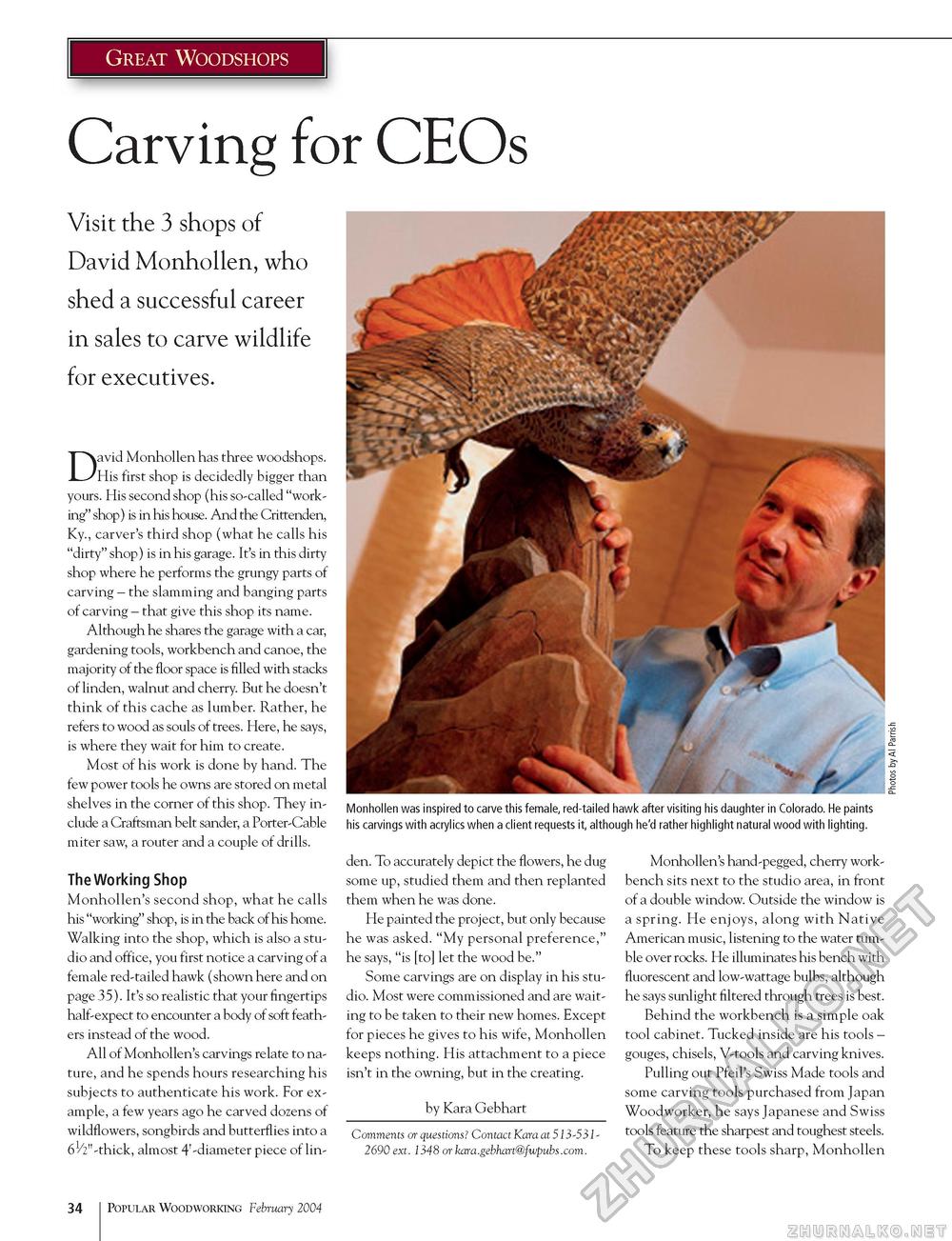

Great Woodshops Carving for CEOs Visit the 3 shops of David Monhollen, who shed a successful career in sales to carve wildlife for executives. David Monhollen has three woodshops. His first shop is decidedly bigger than yours. His second shop (his so-called "working" shop) is in his house. And the Crittenden, Ky., carver's third shop (what he calls his "dirty" shop) is in his garage. It's in this dirty shop where he performs the grungy parts of carving - the slamming and banging parts of carving - that give this shop its name. Although he shares the garage with a car, gardening tools, workbench and canoe, the majority of the floor space is filled with stacks of linden, walnut and cherry. But he doesn't think of this cache as lumber. Rather, he refers to wood as souls of trees. Here, he says, is where they wait for him to create. Most of his work is done by hand. The few power tools he owns are stored on metal shelves in the corner of this shop. They include a Craftsman belt sander, a Porter-Cable miter saw, a router and a couple of drills. The Working Shop Monhollen's second shop, what he calls his "working" shop, is in the back of his home. Walking into the shop, which is also a studio and office, you first notice a carving of a female red-tailed hawk (shown here and on page 35). It's so realistic that your fingertips half-expect to encounter a body of soft feathers instead of the wood. All of Monhollen's carvings relate to nature, and he spends hours researching his subjects to authenticate his work. For example, a few years ago he carved dozens of wildflowers, songbirds and butterflies into a 61/2"-thick, almost 4'-diameter piece of lin Monhollen was inspired to carve this female, red-tailed hawk after visiting his daughter in Colorado. He paints his carvings with acrylics when a client requests it, although he'd rather highlight natural wood with lighting. den. To accurately depict the flowers, he dug some up, studied them and then replanted them when he was done. He painted the project, but only because he was asked. "My personal preference," he says, "is [to] let the wood be." Some carvings are on display in his studio. Most were commissioned and are waiting to be taken to their new homes. Except for pieces he gives to his wife, Monhollen keeps nothing. His attachment to a piece isn't in the owning, but in the creating. by Kara Gebhart Comments or questions? Contact Kara at 513-5312690 ext. 1348 or kara.gebhart@fwpubs.com. Monhollen's hand-pegged, cherry workbench sits next to the studio area, in front of a double window. Outside the window is a spring. He enjoys, along with Native American music, listening to the water tumble over rocks. He illuminates his bench with fluorescent and low-wattage bulbs, although he says sunlight filtered through trees is best. Behind the workbench is a simple oak tool cabinet. Tucked inside are his tools -gouges, chisels, V-tools and carving knives. Pulling out Pfeil's Swiss Made tools and some carving tools purchased from Japan Woodworker, he says Japanese and Swiss tools feature the sharpest and toughest steels. To keep these tools sharp, Monhollen 34 Popular Woodworking February 2004 |