Popular Woodworking 2004-04 № 140, страница 101

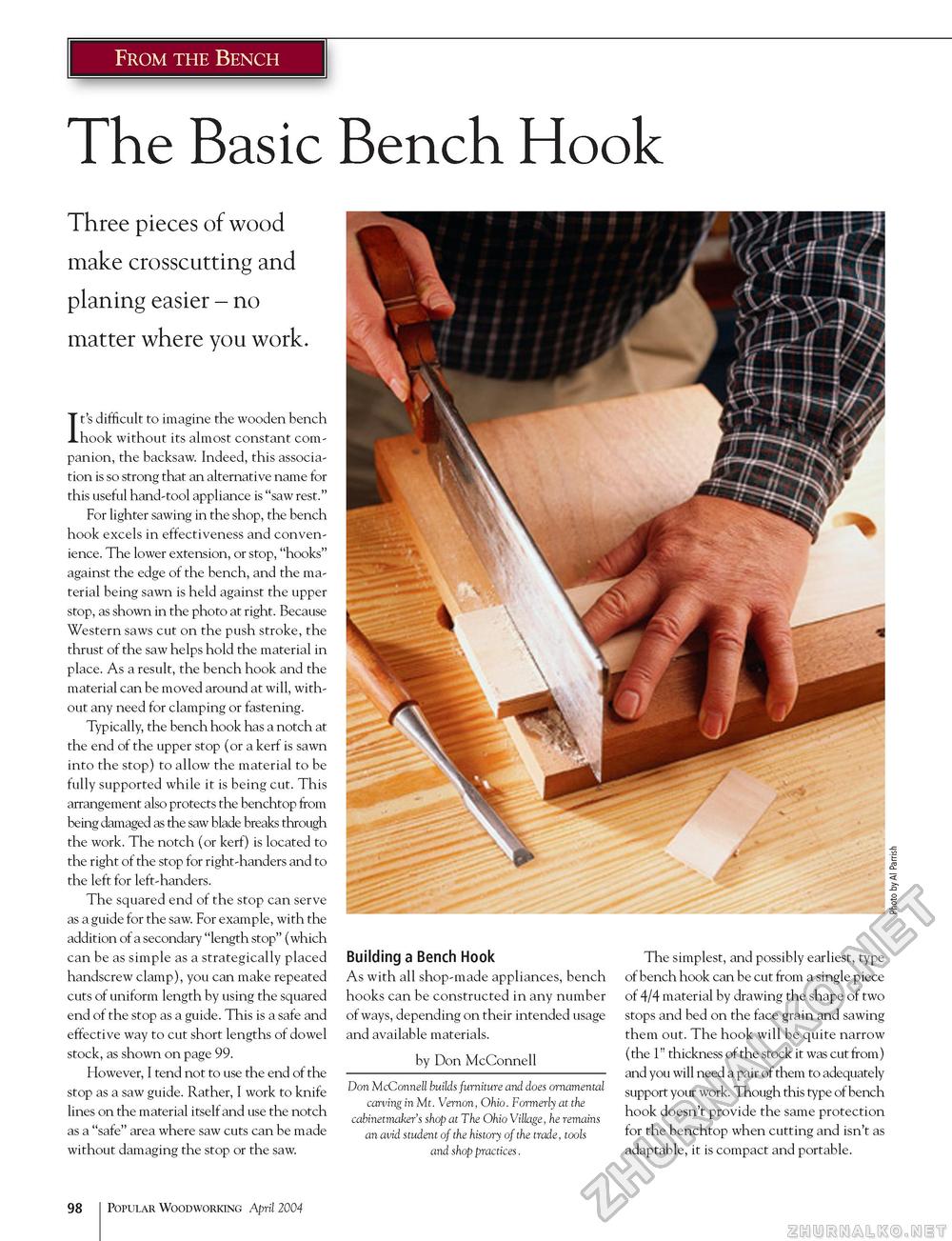

From the Bench The Basic Three pieces of wood make crosscutting and planing easier - no matter where you work. It's difficult to imagine the wooden bench hook without its almost constant companion, the backsaw. Indeed, this association is so strong that an alternative name for this useful hand-tool appliance is "saw rest." For lighter sawing in the shop, the bench hook excels in effectiveness and convenience. The lower extension, or stop, "hooks" against the edge of the bench, and the material being sawn is held against the upper stop, as shown in the photo at right. Because Western saws cut on the push stroke, the thrust of the saw helps hold the material in place. As a result, the bench hook and the material can be moved around at will, without any need for clamping or fastening. Typically, the bench hook has a notch at the end of the upper stop (or a kerf is sawn into the stop) to allow the material to be fully supported while it is being cut. This arrangement also protects the benchtop from being damaged as the saw blade breaks through the work. The notch (or kerf) is located to the right of the stop for right-handers and to the left for left-handers. The squared end of the stop can serve as a guide for the saw. For example, with the addition of a secondary "length stop" (which can be as simple as a strategically placed handscrew clamp), you can make repeated cuts of uniform length by using the squared end of the stop as a guide. This is a safe and effective way to cut short lengths of dowel stock, as shown on page 99. However, I tend not to use the end of the stop as a saw guide. Rather, I work to knife lines on the material itself and use the notch as a "safe" area where saw cuts can be made without damaging the stop or the saw. Bench Hook Building a Bench Hook As with all shop-made appliances, bench hooks can be constructed in any number of ways, depending on their intended usage and available materials. by Don McConnell Don McConnell builds furniture and does ornamental carving in Mt. Vernon, Ohio. Formerly at the cabinetmaker's shop at The Ohio Village, he remains an avid student of the history of the trade, tools and shop practices. The simplest, and possibly earliest, type of bench hook can be cut from a single piece of 4/4 material by drawing the shape of two stops and bed on the face grain and sawing them out. The hook will be quite narrow (the 1" thickness of the stock it was cut from) and you will need a pair of them to adequately support your work. Though this type of bench hook doesn't provide the same protection for the benchtop when cutting and isn't as adaptable, it is compact and portable. 98 Popular Woodworking April 2004 |