Popular Woodworking 2004-04 № 140, страница 102

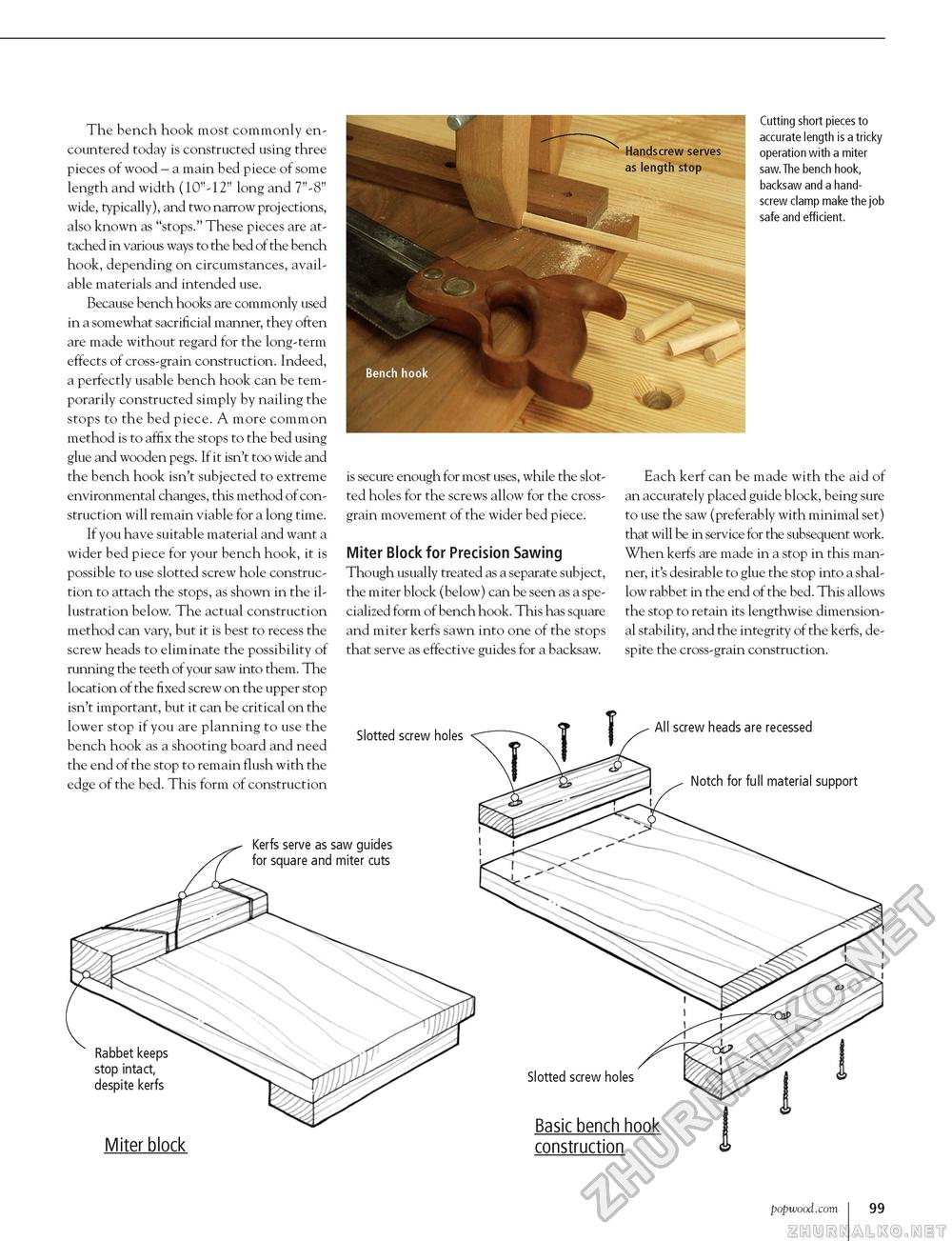

The bench hook most commonly encountered today is constructed using three pieces of wood - a main bed piece of some length and width (10"-12" long and 7"-8" wide, typically), and two narrow projections, also known as "stops." These pieces are attached in various ways to the bed of the bench hook, depending on circumstances, available materials and intended use. Because bench hooks are commonly used in a somewhat sacrificial manner, they often are made without regard for the long-term effects of cross-grain construction. Indeed, a perfectly usable bench hook can be temporarily constructed simply by nailing the stops to the bed piece. A more common method is to affix the stops to the bed using glue and wooden pegs. If it isn't too wide and the bench hook isn't subjected to extreme environmental changes, this method of construction will remain viable for a long time. If you have suitable material and want a wider bed piece for your bench hook, it is possible to use slotted screw hole construction to attach the stops, as shown in the illustration below. The actual construction method can vary, but it is best to recess the screw heads to eliminate the possibility of running the teeth of your saw into them. The location of the fixed screw on the upper stop isn't important, but it can be critical on the lower stop if you are planning to use the bench hook as a shooting board and need the end of the stop to remain flush with the edge of the bed. This form of construction Cutting short pieces to accurate length is a tricky operation with a miter saw. The bench hook, backsaw and a hand-screw clamp make the job safe and efficient. is secure enough for most uses, while the slotted holes for the screws allow for the cross-grain movement of the wider bed piece. Miter Block for Precision Sawing Though usually treated as a separate subject, the miter block (below) can be seen as a specialized form of bench hook. This has square and miter kerfs sawn into one of the stops that serve as effective guides for a backsaw. Slotted screw holes Each kerf can be made with the aid of an accurately placed guide block, being sure to use the saw (preferably with minimal set) that will be in service for the subsequent work. When kerfs are made in a stop in this manner, it's desirable to glue the stop into a shallow rabbet in the end of the bed. This allows the stop to retain its lengthwise dimensional stability, and the integrity of the kerfs, despite the cross-grain construction. All screw heads are recessed Notch for full material support Kerfs serve as saw guides for square and miter cuts Rabbet keeps stop intact, despite kerfs Miter block Slotted screw holes Basic bench hook construction popwood.com 99 |