Popular Woodworking 2004-04 № 140, страница 30

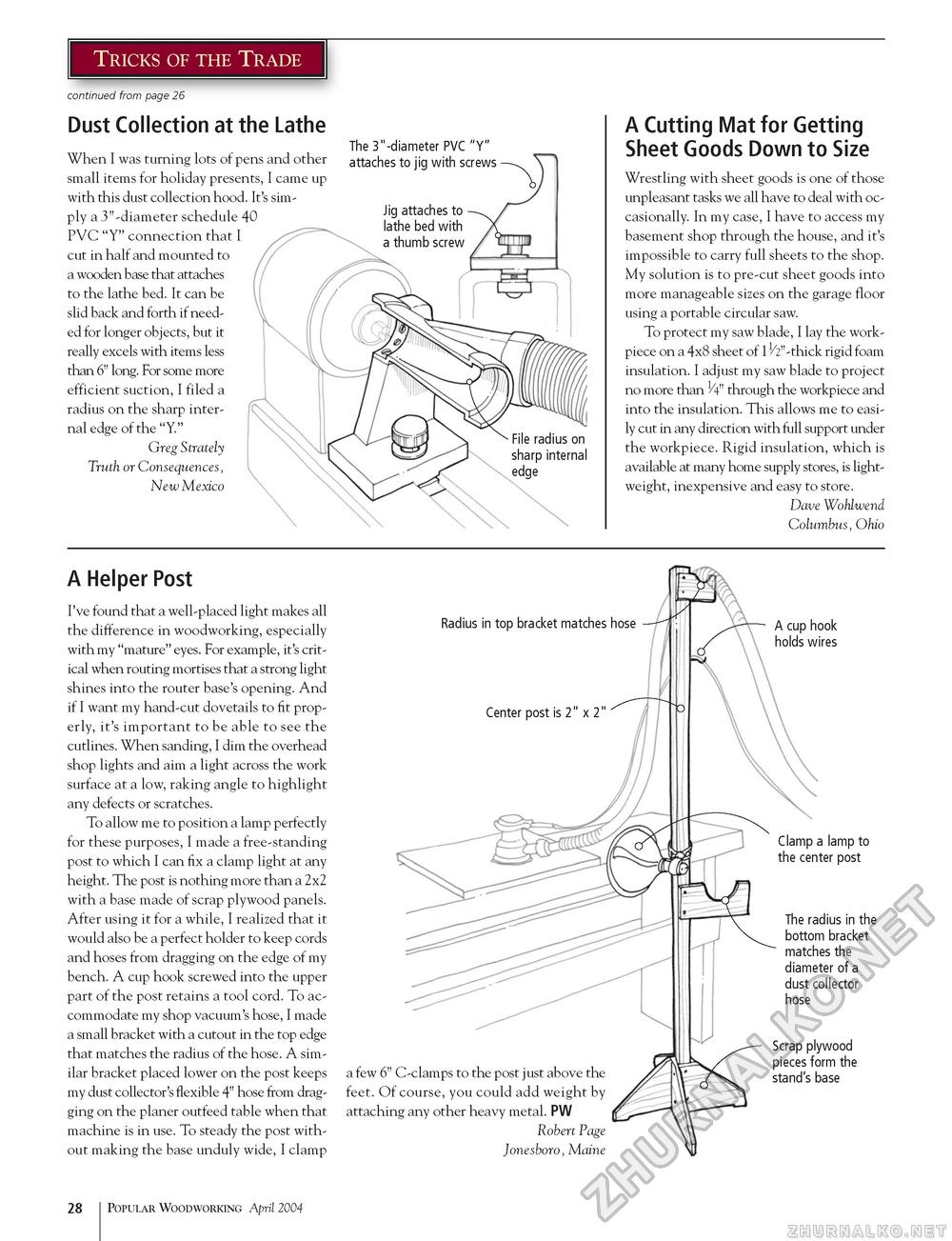

Dust Collection at the Lathe When I was turning lots of pens and other small items for holiday presents, I came up with this dust collection hood. It's simply a 3" -diameter schedule 40 PVC "Y" connection that I cut in half and mounted to a wooden base that attaches to the lathe bed. It can be slid back and forth if needed for longer objects, but it really excels with items less than 6" long. For some more efficient suction, I filed a radius on the sharp internal edge of the "Y." Greg Strately Truth or Consequences, New Mexico The 3"-diameter PVC "Y" attaches to jig with screws Jig attaches to lathe bed with a thumb screw A Cutting Mat for Getting Sheet Goods Down to Size Wrestling with sheet goods is one of those unpleasant tasks we all have to deal with occasionally. In my case, I have to access my basement shop through the house, and it's impossible to carry full sheets to the shop. My solution is to pre-cut sheet goods into more manageable sizes on the garage floor using a portable circular saw. To protect my saw blade, I lay the work-piece on a 4x8 sheet of 11/2"-thick rigid foam insulation. I adjust my saw blade to project no more than 1/4" through the workpiece and into the insulation. This allows me to easily cut in any direction with full support under the workpiece. Rigid insulation, which is available at many home supply stores, is lightweight, inexpensive and easy to store. Dave Wohlwend Columbus, Ohio A Helper Post I've found that a well-placed light makes all the difference in woodworking, especially with my "mature" eyes. For example, it's critical when routing mortises that a strong light shines into the router base's opening. And if I want my hand-cut dovetails to fit properly, it's important to be able to see the cutlines. When sanding, I dim the overhead shop lights and aim a light across the work surface at a low, raking angle to highlight any defects or scratches. To allow me to position a lamp perfectly for these purposes, I made a free-standing post to which I can fix a clamp light at any height. The post is nothing more than a 2x2 with a base made of scrap plywood panels. After using it for a while, I realized that it would also be a perfect holder to keep cords and hoses from dragging on the edge of my bench. A cup hook screwed into the upper part of the post retains a tool cord. To accommodate my shop vacuum's hose, I made a small bracket with a cutout in the top edge that matches the radius of the hose. A similar bracket placed lower on the post keeps my dust collector's flexible 4" hose from dragging on the planer outfeed table when that machine is in use. To steady the post without making the base unduly wide, I clamp Radius in top bracket matches hose Center post is 2" x 2" A cup hook holds wires a few 6" C-clamps to the post just above the feet. Of course, you could add weight by attaching any other heavy metal. PW Robert Page Jonesboro, Maine Clamp a lamp to the center post The radius in the bottom bracket matches the diameter of a dust collector hose Scrap plywood pieces form the stand's base 28 Popular Woodworking April 2004 |