Popular Woodworking 2004-04 № 140, страница 32

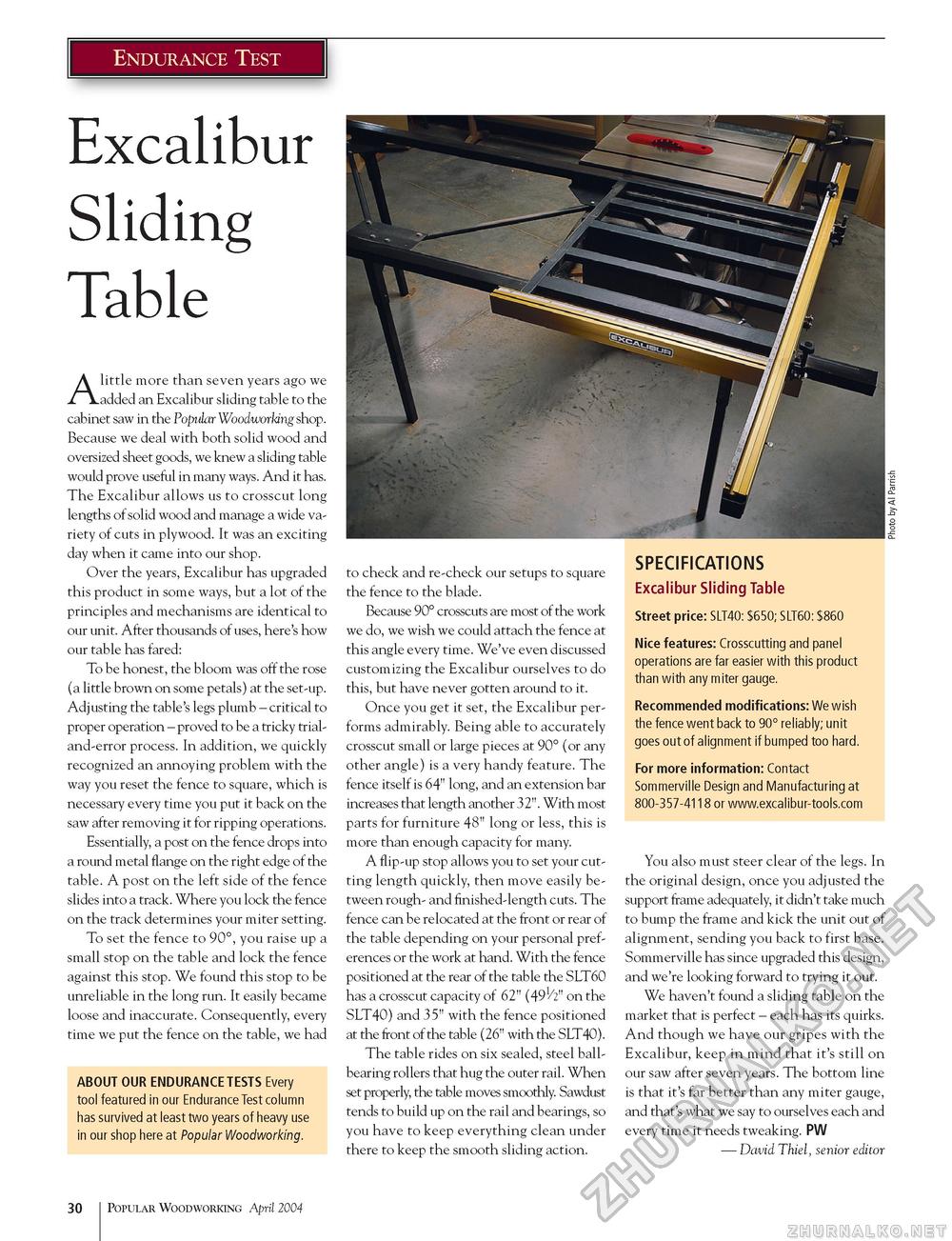

Endurance Test Excalibur Sliding Table A little more than seven years ago we added an Excalibur sliding table to the cabinet saw in the Popular Woodworking shop. Because we deal with both solid wood and oversized sheet goods, we knew a sliding table would prove useful in many ways. And it has. The Excalibur allows us to crosscut long lengths of solid wood and manage a wide variety of cuts in plywood. It was an exciting day when it came into our shop. Over the years, Excalibur has upgraded this product in some ways, but a lot of the principles and mechanisms are identical to our unit. After thousands of uses, here's how our table has fared: To be honest, the bloom was off the rose (a little brown on some petals) at the set-up. Adjusting the table's legs plumb - critical to proper operation - proved to be a tricky trial-and-error process. In addition, we quickly recognized an annoying problem with the way you reset the fence to square, which is necessary every time you put it back on the saw after removing it for ripping operations. Essentially, a post on the fence drops into a round metal flange on the right edge of the table. A post on the left side of the fence slides into a track. Where you lock the fence on the track determines your miter setting. To set the fence to 90°, you raise up a small stop on the table and lock the fence against this stop. We found this stop to be unreliable in the long run. It easily became loose and inaccurate. Consequently, every time we put the fence on the table, we had ABOUT OUR ENDURANCE TESTS Every tool featured in our Endurance Test column has survived at least two years of heavy use in our shop here at Popular Woodworking. to check and re-check our setups to square the fence to the blade. Because 90° crosscuts are most of the work we do, we wish we could attach the fence at this angle every time. We've even discussed customizing the Excalibur ourselves to do this, but have never gotten around to it. Once you get it set, the Excalibur performs admirably. Being able to accurately crosscut small or large pieces at 90° (or any other angle) is a very handy feature. The fence itself is 64" long, and an extension bar increases that length another 32". With most parts for furniture 48" long or less, this is more than enough capacity for many. A flip-up stop allows you to set your cutting length quickly, then move easily between rough- and finished-length cuts. The fence can be relocated at the front or rear of the table depending on your personal preferences or the work at hand. With the fence positioned at the rear of the table the SLT60 has a crosscut capacity of 62 " (491/2" on the SLT40) and 35" with the fence positioned at the front of the table (26" with the SLT40). The table rides on six sealed, steel ballbearing rollers that hug the outer rail. When set properly, the table moves smoothly. Sawdust tends to build up on the rail and bearings, so you have to keep everything clean under there to keep the smooth sliding action. SPECIFICATIONS Excalibur Sliding Table Street price: SLT40: $650; SLT60: $860 Nice features: Crosscutting and panel operations are far easier with this product than with any miter gauge. Recommended modifications: We wish the fence went back to 90° reliably; unit goes out of alignment if bumped too hard. For more information: Contact Sommerville Design and Manufacturing at 800-357-4118 or www.excalibur-tools.com You also must steer clear of the legs. In the original design, once you adjusted the support frame adequately, it didn't take much to bump the frame and kick the unit out of alignment, sending you back to first base. Sommerville has since upgraded this design, and we're looking forward to trying it out. We haven't found a sliding table on the market that is perfect - each has its quirks. And though we have our gripes with the Excalibur, keep in mind that it's still on our saw after seven years. The bottom line is that it's far better than any miter gauge, and that's what we say to ourselves each and every time it needs tweaking. PW — David Thiel, senior editor 30 Popular Woodworking April 2004 |