Popular Woodworking 2004-06 № 141, страница 18

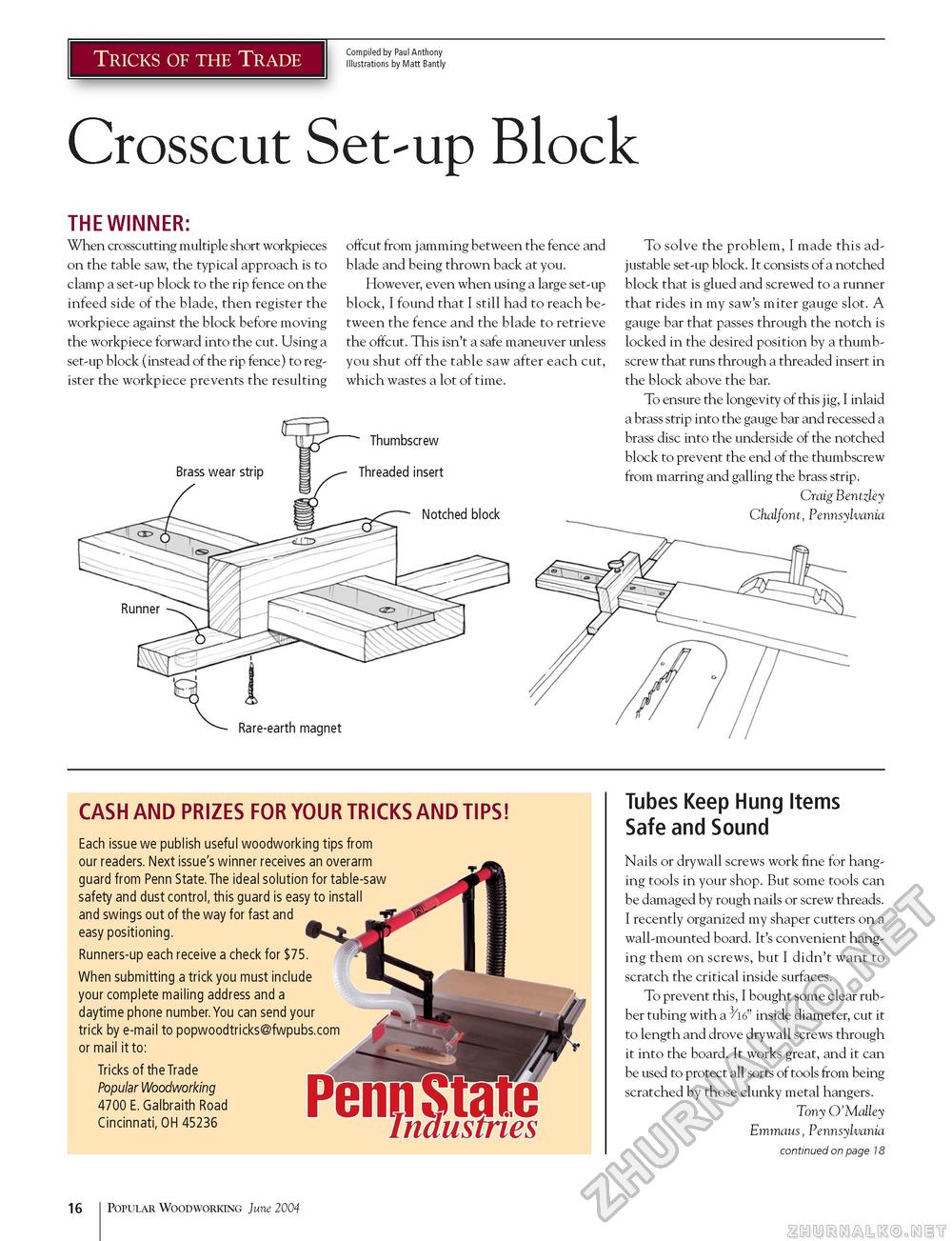

Tricks of the Trade Compiled by Paul Anthony Illustrations by Matt Bantly Crosscut Set-up Block THE WINNER: When crosscutting multiple short workpieces on the table saw, the typical approach is to clamp a set-up block to the rip fence on the infeed side of the blade, then register the workpiece against the block before moving the workpiece forward into the cut. Using a set-up block (instead of the rip fence) to register the workpiece prevents the resulting offcut from jamming between the fence and blade and being thrown back at you. However, even when using a large set-up block, I found that I still had to reach between the fence and the blade to retrieve the offcut. This isn't a safe maneuver unless you shut off the table saw after each cut, which wastes a lot of time. To solve the problem, I made this adjustable set-up block. It consists of a notched block that is glued and screwed to a runner that rides in my saw's miter gauge slot. A gauge bar that passes through the notch is locked in the desired position by a thumbscrew that runs through a threaded insert in the block above the bar. To ensure the longevity of this jig, I inlaid a brass strip into the gauge bar and recessed a brass disc into the underside of the notched block to prevent the end of the thumbscrew from marring and galling the brass strip. Craig Bentzley Chalfont, Pennsylvania Rare-earth magnet CASH AND PRIZES FOR YOUR TRICKS AND TIPS! Each issue we publish useful woodworking tips from our readers. Next issue's winner receives an overarm guard from Penn State. The ideal solution for table-saw safety and dust control, this guard is easy to install and swings out of the way for fast and easy positioning. Runners-up each receive a check for $75. When submitting a trick you must include your complete mailing address and a daytime phone number. You can send your trick by e-mail to popwoodtricks@fwpubs.com or mail it to: Tricks of the Trade Popular Woodworking 4700 E. Galbraith Road Cincinnati, OH 45236 Penn State Industries Tubes Keep Hung Items Safe and Sound Nails or drywall screws work fine for hanging tools in your shop. But some tools can be damaged by rough nails or screw threads. I recently organized my shaper cutters on a wall-mounted board. It's convenient hanging them on screws, but I didn't want to scratch the critical inside surfaces. To prevent this, I bought some clear rubber tubing with a inside diameter, cut it to length and drove drywall screws through it into the board. It works great, and it can be used to protect all sorts of tools from being scratched by those clunky metal hangers. Tony O'Malley Emmaus, Pennsylvania continued on page 18 16 Popular Woodworking June 2004 |